Pillars of the Industry: An Interview with Tony Malisani

Peter J. Marcucci

Special Contributor

(Hover over photos for captions)

The Marble Institute of America (MIA) has been the preeminent resource of information for the natural stone industry for over six decades.

The Marble Institute of America (MIA) has been the preeminent resource of information for the natural stone industry for over six decades.

With nearly 2,000 worldwide members, the MIA is the voice and oracle for the many quarries, importers, distributors and fabricators including the architectural and design sector. It is, and will remain, the most committed organization with the highest standards of workmanship and principles in our industry.

With nearly 2,000 worldwide members, the MIA is the voice and oracle for the many quarries, importers, distributors and fabricators including the architectural and design sector. It is, and will remain, the most committed organization with the highest standards of workmanship and principles in our industry.

Directing the MIA is newly elected President Tony Malisani. His company, Malisani Inc., was started in 1928 by Art Malisani, and since then the company has produced some of the finest fabrication work in Montana.

Directing the MIA is newly elected President Tony Malisani. His company, Malisani Inc., was started in 1928 by Art Malisani, and since then the company has produced some of the finest fabrication work in Montana.

Tony, congratulations on your appointment as 2014 President of the Marble Institute of America. Could you please explain more about your background in the stone industry?

“I am an owner, along with my brother Art, of Malisani Inc. in Great Falls, Montana. We are a third generation contracting firm that specializes in stone, ceramic tile and terrazzo. I tell people that we are a company that measures, cuts, polishes and sets hard products. We like to focus on what we can accomplish with the employees and the tools that we have as opposed to products we produce.

“I am an owner, along with my brother Art, of Malisani Inc. in Great Falls, Montana. We are a third generation contracting firm that specializes in stone, ceramic tile and terrazzo. I tell people that we are a company that measures, cuts, polishes and sets hard products. We like to focus on what we can accomplish with the employees and the tools that we have as opposed to products we produce.

“I have been at Malisani Inc. full-time for the past 26 years and also have many childhood memories of helping out my father, uncle, and brother with projects. Pulling weeds in our storage yard was a rite of passage. We do work in both the commercial and residential markets and are very proud of both our long history and the quality of projects Malisani Inc. has produced all these years.

“In the past, I served on the MIA committee that designed the accreditation program. We were the seventh company to receive the MIA Accredited Natural Stone Fabricator designation. Additionally, I have spoken around the country and at StonExpo and Coverings for the last 5 years. My wife, who is my best friend, is a Lieutenant Colonel in the Army Reserves and has served on three deployments. We have four children; two of them are cadets in the ROTC program.”

So where do you see our industry at this point in time?

“I see our industry more closely aligned than it has been in many years and possibly ever. The MIA Board of Directors attended the Natural Stone Council annual meeting at StonExpo in Las Vegas January 27, 2014. Almost every stone association in the country had representation in that room.

“The topics discussed were timely and relevant. This type of collaboration is what will be needed in our industry if we are to challenge burdensome regulations, effect related legislation, maintain standards, and educate the public about the beauty and value of natural stone. The MIA board has also charged the staff to look for collaboration opportunities – it is the future.”

Where do you see the industry going in the next ten years?

“I think that, if we can continue to leverage the high level of cooperation and collaboration addressed earlier, we will have a united industry that has the organizational capacity to not only defend our industry but also to promote the ultimate natural resource, stone. We will have sustainable, ethical standards for production, installation and restoration of stone that are recognized internationally.

“As long as we focus on the common interests of the different segments of the industry, I believe that there is no end to what we can accomplish. The establishment of guidelines and standards to communicate between companies leads to better understanding and successful commerce. It is in the promotion of our industry and education of the public that the most potential exists.”

These days I cannot watch a night’s worth of news without hearing that employment has fallen behind and that those left behind in this lackluster labor market need to further their education to qualify to get the jobs that are becoming available. Yet in my interviews with so many owners and CEOs of fabrication companies this past year, many are desperately looking for experienced, or at least trainable new employees to fill their growing needs.

Can the MIA assist in this search and training, or is it solely up to these fabrication companies to find or give their new team members on-the-job-training? How does the MIA square on this?

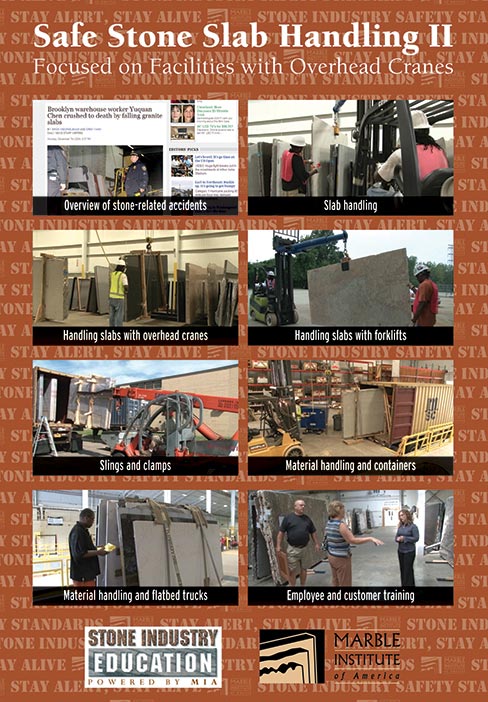

“We have been leaders and innovators in this aspect of business development for many years. My company uses some of the safety and promotional videos as initial training aids for new hires. The Stone Industry Education series has helped many contractors and fabricators with the process of developing not only entry level employees but also those who want to advance their careers.

“We are now starting work on new educational resources (such as online classes) that will be available to help guide [new to the industry workers] with basic knowledge acquisition. I also feel that we as an industry need to raise our standing in the construction industry. We need to demand good work so that we are seen as a trade to aspire to, and not as a last resort.

“The growth of the accreditation program for contractors and fabricators will give the public and potential employees the confidence that this is truly a noble profession that is worth the time and effort required to become a true craftsman.”

The MIA sets the standard with guidelines for shop safety as well as fabrication and installation—even for stone flooring. Many years ago I personally witnessed the MIA going to bat for a fabrication company that had completed a marble floor installation adhering to those guidelines, but due to the fault of another contractor, that company was dragged into litigation by the homeowner.

Due to the MIA’s support in the courtroom, that fabrication company was released of any liability. That was a big relief for them and they were very happy they were an MIA member. In what other ways can the MIA help its members, be it with standards, guidelines or litigation?

“The MIA was developed solely to help its members and we do that in many different ways with many different resources. The safety resources are possibly the most important training resource the MIA has to offer. We offer training videos, safety meeting guides and more. There are more concerns and legal issues with safety in our current environment than with many other business activities. We also offer business development resources for the member companies and offer many educational opportunities for managers and staff.

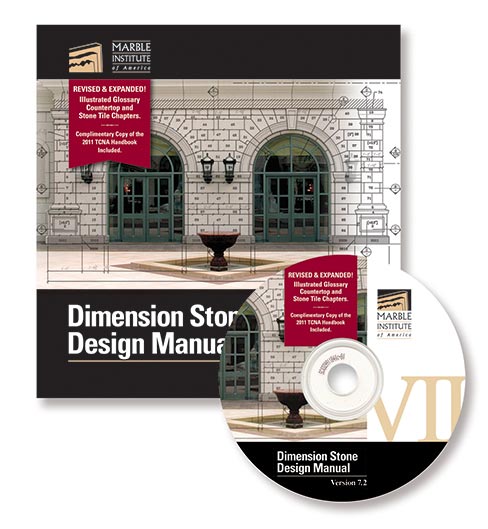

“One of the most important functions of the MIA is to continue to update the Dimensional Stone Design Manual and the other technical modules we have published over the years. If you are in compliance with the standards, you will not have problems with clients or their lawyers. The standards we produce are not the measures of a perfect job. They are a guide to what level of performance should be achieved no matter how difficult the materials or the conditions. They ensure clear communication of performance, appearance and expectations.

“I am amazed that more contractors and fabricators do not reference the standards of the Dimensional Stone Design Manual in their specifications, transmittals, contracts and purchase orders. Many lawsuits and misunderstandings could be avoided by clear communications and that is what a standard does.

“For the member that wants to put themselves out in front of the competition, we offer the only credentialing programs in the stone industry. An MIA accreditation tells the world that the company has proven itself and is an ethical, well-run, knowledgeable enterprise.

“The best thing a company can do is to realize when they need help and to seek it out before it becomes an issue. The MIA is a definitive source for information on techniques, processes, procedures, standards, and safety.

“Finally, for those that need it, we have a highly qualified technical director who can help them with questions and do inspections if required.”

In the past, the MIA has taken on some tough issues such as radon. What other key issues is the MIA currently working on?

“The EPA has been working to decrease the allowable levels of free silica in the air at worksites and fabrication facilities. These decreases would be extremely difficult to comply with. Many of the members of various affected industries have succeeded in getting the comment period extended.

“The cases of silicosis have been extremely low since the last change in levels took effect. So low in fact, that we do not believe that the implementation of this onerous new threshold will make a difference, and we have been working to get this proposed new threshold thrown out.

“It has become apparent to us that we are in need of a coordinated effort to represent our industry in the legislative and regulatory arenas. To that end we have started to build a legislative outreach program for members of our industry to get involved. We are looking for politically inclined individuals and companies that would be willing to maintain a communications conduit to our various representatives.

“We need to make sure that in the halls of power in our industry our story is being told. I would encourage anyone who has an interest in politics to contact us at legislative@marble-institute.com. Our goal is to have a volunteer who will serve as contact for every congressperson or their staff.”

What other issues or regulations await on the horizon to be grappled with?

“I am sure that we will have an ever increasing burden of regulations from MSHA, OHSA and the EPA with every new year. I have been in this business for a long time, and I am still amazed by all of the advances in safety and environmental controls that we have made through the years.

“Our quarries, warehouses, jobsites and fabrication facilities, are vastly improved over those of ages past and even those of ten years ago. I think that we as an industry will need the innovation and creativity of our members to continue to improve our workplaces and our workspaces.

“The one thing that has changed is that we are now a more proactive industry. In 2013 the MIA, with the help of over a hundred donors, went through the process of having a new scientific study of radon exposure to granite quarriers and fabricators peer reviewed and published as a white paper last year. This means that the only documented recognized scientific proof of radon levels in granite shows that there is no danger from exposure to granite countertops in a home, as well as the workplace. This process was barely completed when we had to use the white paper to refute false claims made on The Doctors talk show.

“Years ago something like this would have caused people to rethink their choice of stone or to take a Geiger counter to pick out countertops. The future will no doubt hold more environmental regulations and guidelines. That is why we are fully committed to helping the National Stone Council develop the sustainability standard for the dimension stone industry.”

So what can people like myself as well as the many owners of quarries, distributors and fabricators do to help promote sustainability in the industry?

“By joining one of the associations that make up the National Stone Council, you are helping with the effort. Donations to fund this initiative can be sent directly to the National Stone Council at www.naturalstonecouncil.org.”

So why should owners of new or existing fabrication companies (especially smaller ones) become members of the MIA?

“The companies that benefit the most from MIA membership are those without the money and expertise to develop the resources that make a company operate more efficiently and profitably. The cost of membership is easily recouped by any company that takes advantage of the safety, human resources, educational, and technical resources that are available to them.

“If you need forms for complaint resolution processes, we have them. If you are not sure what mortar meets an ANSI spec on a paving project, we can help you figure that out. Can a particular limestone be used in a steamer shower? We can help you with that. The MIA is what helps smaller and new companies successfully complete projects. Companies that can be successful become bigger, older companies.”

What new directions, if any, would you like to see the MIA take in the near future, and as President how will you accomplish them?

“The MIA is an association of stone industry companies. Our membership covers the entire industry from quarrying to installation and restoration. As an association we are charged to represent the interests of our members of whom I am only one. As President I can only accomplish what you as members support. So I would encourage everyone who is reading my words to become a member of the MIA.

“We have payment programs that make membership achievable for everyone. Your support comes not only in the form of dues but also in your advocacy, so I would ask that you please volunteer to help in whatever way you can. Our volunteers are our most valuable resource.

“I look at my position as President as a service position. I welcome your comments and suggestions and encourage you to contact me directly at miaexecbod@marble-institute.com.”

Tony, thank you for taking the time to be part of this story.

Peter J. Marcucci has over 25 years of fabrication experience in the stone industry. Send your comments to our Contacts page.