The Elberton Granite Association

Keeping Elberton, Georgia’s World Market Position Strong and Focused Since 1951

Peter J. Marcucci

Special Contributor

Photos used courtesy EGA

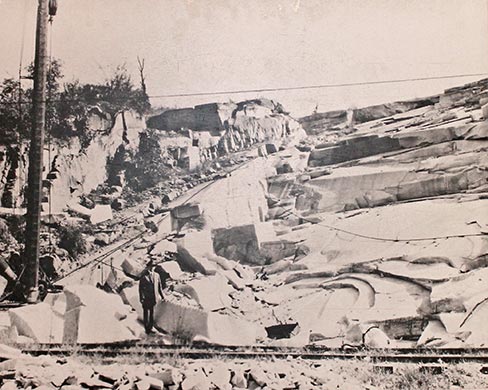

Nestled within the scenic rich counties of Elbert, Oglethorpe, Madison, Wilkes and Green, lies a supremely hard deposit of granite 35 miles long, 6 miles wide and 3 miles deep known as Georgia Gray.

Nestled within the scenic rich counties of Elbert, Oglethorpe, Madison, Wilkes and Green, lies a supremely hard deposit of granite 35 miles long, 6 miles wide and 3 miles deep known as Georgia Gray.

This deposit, composed mainly of gray feldspar, quartz and mica, has unquestionably set the benchmark for uniformity and durability while carving its way into a legacy of time-honored history, and into our hearts.

This deposit, composed mainly of gray feldspar, quartz and mica, has unquestionably set the benchmark for uniformity and durability while carving its way into a legacy of time-honored history, and into our hearts.

It was the late 1870s that this legacy began.

It was the late 1870s that this legacy began.

The sluggish post American Civil War economy that had held a grip on the southern states for a decade was now thankfully rebounding throughout.

Likewise at this time and due mainly to the newly discovered granite deposit, the rural farming community of Elberton, Georgia, was also moving forward; so far though, no one at this time knew the size of this deposit; they only knew the hard facts of the quality of the stone by what now stood unearthed and naked.

The quantity of the hard gray that lay buried would continue to remain one of nature’s secrets—at least for a while longer.

In 1882, a small quarry had opened to supply the area with needed gravel for railroad construction and dimensional blocks for home construction.

In 1882, a small quarry had opened to supply the area with needed gravel for railroad construction and dimensional blocks for home construction.

Within seven years later, the opening of a quarry by Dr. Nathaniel, saw the influx of craftsmen and artists to the area beginning with sculptors Arthur Beter and Peter Bertoni, who began using the gray for monument work somewhere around the turn of the 20th century.

As the quarry and manufacturing operations grew throughout the five counties, so grew the population, and by 1930 the granite rich Elberton district had also grown talent rich with American and European artisans pursuing the American dream of prosperity. The stage was set, and the Elberton district was close to accepting its destiny as “Granite Capitol Of The World.”

As the quarry and manufacturing operations grew throughout the five counties, so grew the population, and by 1930 the granite rich Elberton district had also grown talent rich with American and European artisans pursuing the American dream of prosperity. The stage was set, and the Elberton district was close to accepting its destiny as “Granite Capitol Of The World.”

By 1947, an America still basking in its World War II victory was eager to get back to work.

By 1947, an America still basking in its World War II victory was eager to get back to work.

Manufacturing plants that had built tanks and guns were now building cars and construction equipment, and a country awash in new technologies was poised to burst at the seams, and according to the records, so was Elberton.

Stone quarriers and manufacturers big and small were cutting rock around the clock to keep up with consumer demand, and the previous Elberton of yesteryear, had now grown into a Mecca of quarries and manufacturers and the largest supplier of monuments and mausoleums in the world.

Stone quarriers and manufacturers big and small were cutting rock around the clock to keep up with consumer demand, and the previous Elberton of yesteryear, had now grown into a Mecca of quarries and manufacturers and the largest supplier of monuments and mausoleums in the world.

Now more than ever an organization was needed to keep the quarriers and manufacturers unified and productive—enter, the Elberton Granite Association (EGA).

Now more than ever an organization was needed to keep the quarriers and manufacturers unified and productive—enter, the Elberton Granite Association (EGA).

“The EGA was established in 1951 because a lot of area quarriers and manufacturers had the foresight to realize that they had a great product and a lot of it,” said EGA Executive Vice President Doyle Johnson, explaining that cemetery memorials are 90% of what they do in the Elberton district.

“They knew if they were going to realize the full potential of this area, their granite products would need to be promoted nationally as well as internationally, and that is the main reason we exist.”

In regard to why Elberton granite is so popular, Johnson said it is mainly due to the size and consistency of the deposit, and that area quarriers have barely scratched the surface, adding, “Geologists have estimated it is about 2-3 miles in depth.

In regard to why Elberton granite is so popular, Johnson said it is mainly due to the size and consistency of the deposit, and that area quarriers have barely scratched the surface, adding, “Geologists have estimated it is about 2-3 miles in depth.

We’ve been quarrying this material since the 1880s, and it is now 2013, and our deepest quarry is not more that 175 feet deep. It just goes to show you that there is a seemingly endless supply.”

A seemingly endless supply, indeed! Elberton produces about a third of the memorials used in the United States as well as holding a consistent major market share internationally. To accomplish this, the EGA attends 10-11 tradeshows per year in order to represent every one of their members, even if those members are at the same show representing themselves.

The EGA also produces a quarterly magazine called the Elberton Graniteer. And as if this wasn’t enough, the EGA offers a one week monument retailers basic course where they allow industry people from Anywhere USA to improve their knowledge and techniques, and also learn about symbolism and nomenclature, and additionally the process from quarry to finished product.

During this week, visitors also get to tour a local mausoleum plant and etching studio and visit the many Elberton district supply houses and transportation companies.

“We are still the largest association in the United States,” Johnson said, “and our members are entitled to benefits such as workers’ compensation, as well as the Mine Safety and Health Administration’s (MSHA) compulsory first aid and CPR training.

“Forklift and explosive training as well as dust and noise monitoring are also services that we provide. We have 35-40 quarries operating at any given time, but some of these, believe it or not, are run by one owner and only two employees.

“Then you’ve got the larger ones that employ fifty people, but the fact of the matter is that the majority employ about 5-8 people, and when you’ve got the actual owner out there operating the crane or doing whatever, he has no time for human resource duties to interfere with his production.

That’s where we come into play. The EGA provides to the smaller operator what ordinarily larger corporations’ human resources would do.”

Johnson then explained that for quarriers or manufacturers to be a considered for a voting, sustaining, or associate membership to the EGA, they must fit the following criteria: operate a store front within the Elberton district’s five counties and also produce at least 70% of their income from the district.

That being said, after approval, members must keep up with all EGA requirements and obligations, including the mandatory yearly dues.

A Prosperous Future

“Our quarry operators and manufacturers are constantly upgrading equipment to save time and produce the highest quality product for their customers. In our quarries, new diamond wire saws have been installed, which allow more rock to be extracted with less dust and noise, thereby creating a much safer environment for the employees.

“The same technology is being used in manufacturing plants, enabling manufacturers to create unique shapes and cuts for custom designs. Over the years, laser etchers have made vast improvements, and these machines get faster and the quality improves with each new model.

“Our quarry operators and manufacturers are always looking to use the newest and best equipment to not only benefit their customers by creating top notch products in a reasonable amount of time, but to also benefit their employees with safer and more efficient working conditions.”

It’s true that competing with imported cost-cut stone has been difficult for the Elberton district over the last decade, and many of the companies that were hanging on, hoping that the overall economy of the country would improve, have either fallen by the wayside or been consumed by the stronger, larger ones.

It’s also true that in the world of business, especially the stone business, change is inevitable, and having tough skin to stay in the game is vital.

The Elberton Granite Association has had that skin in the game since 1951, and out of necessity will continue to be the Elberton district’s preeminent leader by building partnerships nationally and internationally for countless years to come.

Peter J. Marcucci has over 25 years of fabrication experience in the stone industry. Send your comments to our Contacts page here at the SRG website.