Indiana Limestone Company – Going Forward Into Another Century of Growth

Torin Dixon

Special Correspondent

Created By Nature. Crafted By Man” is the tag line of the Indiana Limestone Company (ILC) located in the heart of limestone country: Oolitic, Indiana.

Created By Nature. Crafted By Man” is the tag line of the Indiana Limestone Company (ILC) located in the heart of limestone country: Oolitic, Indiana.

South Central Indiana is home to one of the largest Limestone deposits in the world. The town, incorporated in 1901, took its name from the Oolite (egg stone) sedimentary rock formed from ooids, or spherical grains composed of concentric layers. Indiana Limestone is composed of calcium carbonate, magnesium carbonate and quartz. This resource was formed during the Mississippian age, where the entire region was once an inland sea.

The high-quality, color and consistency of the limestone soon became a favorite building material in the area.

The high-quality, color and consistency of the limestone soon became a favorite building material in the area.

The first quarry opened in 1827 and with the completion of the New Albany and Salem railroad in 1853, work began on the first major building constructed of Indiana Limestone, that being the Unites States Custom House and Courthouse in Louisville, Kentucky.

The railroads also made it easier to ship limestone out to eastern markets. Since these early days, numerous limestone quarries and factories have been in continuous operation ever since.

An early 1855 account from the Indiana Bedrock Industry time-line describes the early quarry process. “All work done by hand and horse: pick and shovel; wheelbarrow; horse-drawn dump-cart; 10-20 feet long hand drills, as many as 10-20 aligned 34 inch holes for black powder charges blasted simultaneously to loosen a large rock ledge; broken into blocks using hand drills, tap hammers and wedges; slabs sawn 10-12 feet long by 2-man crosscut saws; lifting of blocks up to 80 cubic feet done by wooden derricks and booms; steel guy rods or manila guy ropes; and hoisting by hand or horse-power.”

An early 1855 account from the Indiana Bedrock Industry time-line describes the early quarry process. “All work done by hand and horse: pick and shovel; wheelbarrow; horse-drawn dump-cart; 10-20 feet long hand drills, as many as 10-20 aligned 34 inch holes for black powder charges blasted simultaneously to loosen a large rock ledge; broken into blocks using hand drills, tap hammers and wedges; slabs sawn 10-12 feet long by 2-man crosscut saws; lifting of blocks up to 80 cubic feet done by wooden derricks and booms; steel guy rods or manila guy ropes; and hoisting by hand or horse-power.”

Oh, how times have changed.

In 1926, with the continued and widespread use of this quality resource, twenty-four area companies merged to form Indiana Limestone Company. This merger represented nearly 90% of the area limestone producers. This seems to be quite an interesting event given that so many diverse companies, owners and managers were both willing and able to set aside their personal interests for the sake of the collective whole.

In 1926, with the continued and widespread use of this quality resource, twenty-four area companies merged to form Indiana Limestone Company. This merger represented nearly 90% of the area limestone producers. This seems to be quite an interesting event given that so many diverse companies, owners and managers were both willing and able to set aside their personal interests for the sake of the collective whole.

It seems that our modern day politicians could learn a great lesson from this form of cooperation.

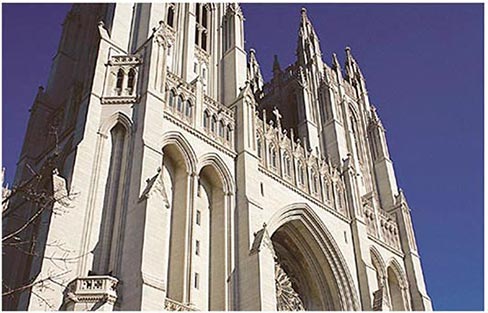

Since its 1926 inception, Indiana Limestone Company has been the limestone producer for many famous buildings including the Empire State Building, the National Cathedral, and the Pentagon, where Indiana Limestone Company pulled 460,000 cubic feet out of the ground for the original construction.

Since its 1926 inception, Indiana Limestone Company has been the limestone producer for many famous buildings including the Empire State Building, the National Cathedral, and the Pentagon, where Indiana Limestone Company pulled 460,000 cubic feet out of the ground for the original construction.

Following the September 11th attack on the Pentagon, Bybee Stone was chosen to reproduce the original shot-saw finish to match the original stone texture.

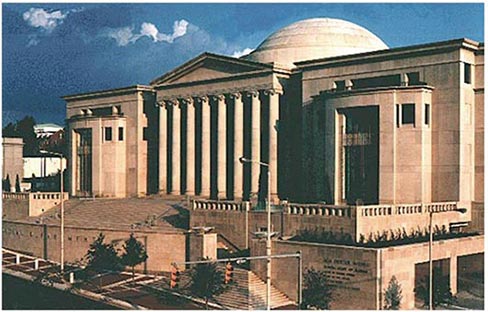

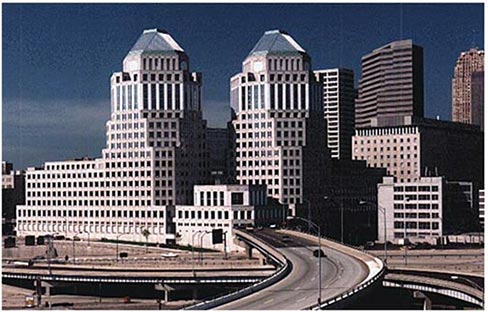

For decades since, Indiana Limestone Company has produced limestone for hundreds of institutional buildings like the Ronald Reagan Building & International Trade Center, the National Archives, and the Alabama Judicial Center.

For decades since, Indiana Limestone Company has produced limestone for hundreds of institutional buildings like the Ronald Reagan Building & International Trade Center, the National Archives, and the Alabama Judicial Center.

Countless high-end residential projects have used Indiana limestone for cladding, columns, quoins, paving, sills and other architectural elements, both for the consistent colors and beauty, as well as its lasting durability. Used in cut as well as split finishes, Indiana Limestone is also a highly sought after material for landscape elements.

Countless high-end residential projects have used Indiana limestone for cladding, columns, quoins, paving, sills and other architectural elements, both for the consistent colors and beauty, as well as its lasting durability. Used in cut as well as split finishes, Indiana Limestone is also a highly sought after material for landscape elements.

Features such as stone walls, garden paving, pool coping, and steps and stairs. There seems to be no limit to the uses of Indiana Limestone, and ILC has been one of America’s most consistent limestone producers.

In 2003, Indiana Limestone Company was acquired by Johnson Ventures, Inc. Dick Johnson spent two decades building one of the largest convenience store chains in America. In 2001, Johnson sold the 225 store chain to a Canadian retailer and started Johnson Ventures.

In 2003, Indiana Limestone Company was acquired by Johnson Ventures, Inc. Dick Johnson spent two decades building one of the largest convenience store chains in America. In 2001, Johnson sold the 225 store chain to a Canadian retailer and started Johnson Ventures.

The investment group held and developed Indiana Limestone Company until 2010 when it was sold to Resilience Capital Partners, an equity group, who in 2009 previously acquired Victor Oolitic Stone Company in a Chapter 11 auction. This acquisition firmly solidified Resilience Capital Partners North Coast Minerals portfolio as a major U.S. Player in minerals and mining.

Now with quarries covering more than 4,000 acres, and with more than 100 years of proven reserves, the combined companies are now situated to be the largest producer of limestone building materials in North America, capitalizing on the collective knowledge of generations of highly skilled workers.

Now with quarries covering more than 4,000 acres, and with more than 100 years of proven reserves, the combined companies are now situated to be the largest producer of limestone building materials in North America, capitalizing on the collective knowledge of generations of highly skilled workers.

Speaking with ILC’s Vice President of Operations, Mr. Duffe Elkins about the 2010 purchase by Resilience Capital Partners, he indicated there were some adjustments to be made in facilities and personnel, but they have worked through those challenges.

This past winter, Indiana Limestone Company operations were slowed by a labor dispute that was settled in January. Last November, Millworkers voted to strike, rejecting work rules concessions demands by the equity group. ILC’s Millworkers prevailed in winning key demands.

At the same time, Indiana became the 23rd state to adopt “Right to Work” rules. Now, workers will not be forced to join a union as a condition of employment, along with other rights and provisions.

Going forward with new labor contracts in place and the new Right to Work dynamics at play, it is uncertain what effect this may have on continued operations, or how these changes may effect the objectives of the owners.

I asked Mr. Elkins how the economic decline had affected ILC’s business. He indicated that they are doing less government building projects, but are quite busy with major institutional projects including Grand Valley State University, the First Presbyterian Church of Tulsa, and a major expansion of the School of Business on the campus of Indiana University.

Additionally, they are always busy producing blocks and slabs for both their Fabricator and Distributor networks.

With more than 170 employees currently working at the end of their busiest season, Indiana Limestone Company is looking into the future and stands poised to capitalize on future rebuilding opportunities. They are facing current economic challenges head-on, and continuing to craft a legacy that will endure for generations to come.

For more than 85 years, Indiana Limestone Company has quarried, cut, shaped, and installed quality limestone into countless American architectural projects bringing beauty, durability, and lasting value to property owners, architects and developers.

In the process, the ILC provided hundreds of well-paying jobs to several generations of Indiana’s area citizens.

These workers “Built It” and are a part of an energetic and enduring industrial American workforce.