Prioritize – Focus – Finish

Rick Phelps

Synchronous Solutions

“What gets measured gets done” – a timeless adage that is always relevant.

Our Synchronous Flow Operating System (SFOS) is a management system and structure that forces countertop fabricators to align their business so that “what gets measured” is driving what actually is what is most important “to get done” for the success of the business.

Far too often, there is little to no connection between what is being measured/worked on, and what is required for success. In many cases, nothing is actually measured at all because of the owner’s belief that “my team knows what to do, and gets it done’!” Rarely is that the truth.

In other cases, the leadership team makes the effort, identifying things they think they should work on every quarter, and then don’t, because frankly, they just were not important enough to merit the effort.

I recently observed a review meeting of one such team. They were most of the way through the quarter and virtually no work had been performed on their “rocks”(key projects). At the end of meeting, they all rated the meeting a “9” or “10”. I was in the back corner thinking “…and from the Russian judge, ‘2’,” and about how much fun it was going to be to teach this team how to create goals aligned with the needs of their business – projects aligned with achieving those goals – and how to hold each other to account!

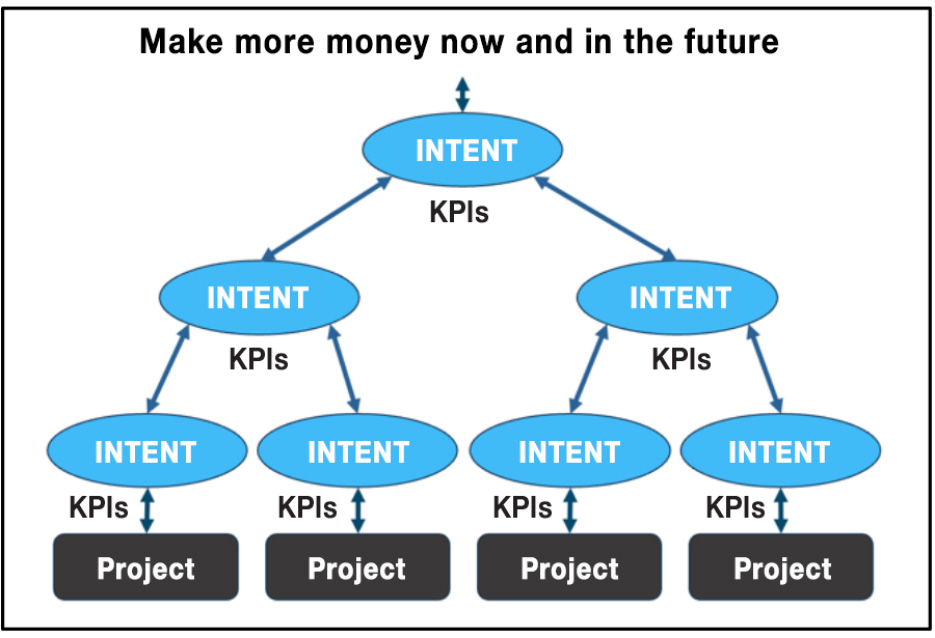

When we align a business, we talk in terms of “Intent,” and start with the generic Intent of every business: “To make more money now and in the future.” We then cascade that Intent down through the business to align all management roles, and eventually ALL roles with that Intent of the business. The idea here is that everyone in the business can look up at the stated intent of the business, or their department, and develop a clear understanding of what their intent needs to be contribute to the overall success of the business.

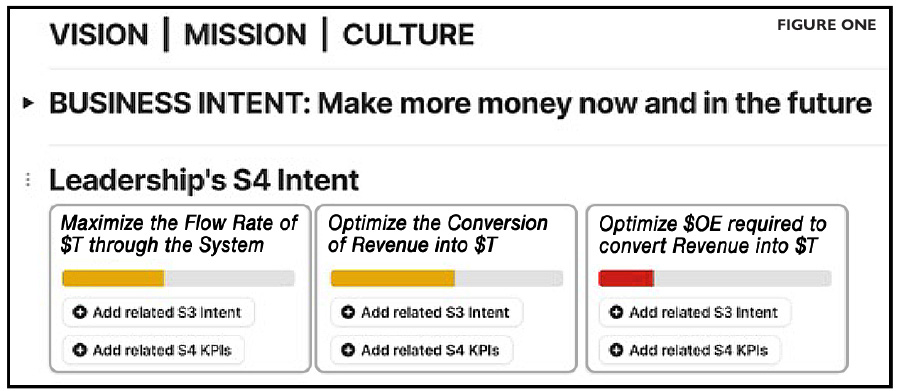

For the General Manager (S4) role, the generic Intent of the business can be broken into three core Intents that need to be true to achieve “making more money now and in the future.” These are shown in Figure One.

Sticking with the first Intent: “Maximize the Flow Rate of $T through the system,” we can follow the logic tree for this core Intent down through the business.

To achieve this Intent, what would the Fabrication Shop Manager’s ‘intent’ need to be?

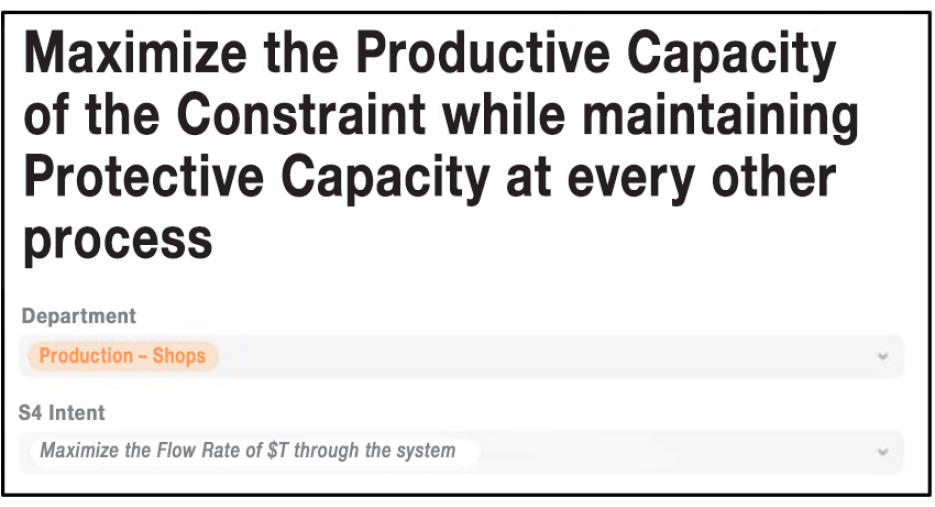

The Shop Area Manager’s Intent would logically be “to maximize the production process that limits the flow of jobs through the shop,” and looks like this in our SFOS software:

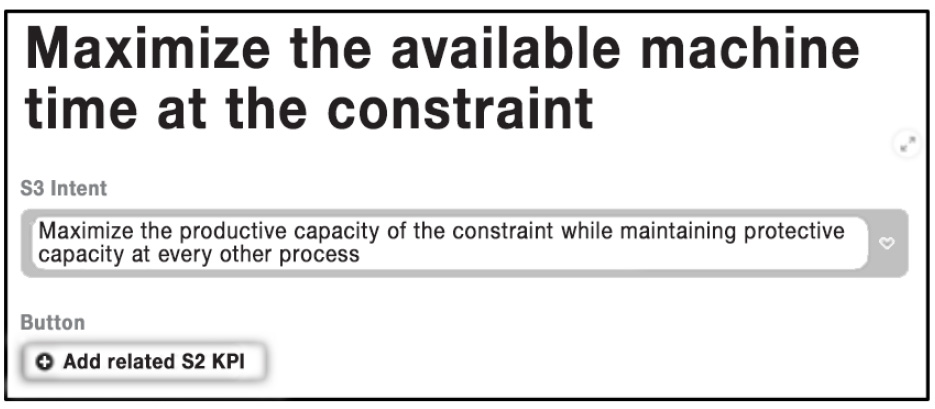

This in turn translates to the Section Manager in charge of Constraint to have the Intent:

The team working at the Constraint Process can look at this ‘Intent’ and translate it into what they need to do to maximize the time available at this critical process: things like fast changeovers, preventive maintenance, etcetera.

By using “Intent” instead of the terms “Objectives” or “Goals,” we make the alignment process more approachable, relatable, or perhaps “human.”

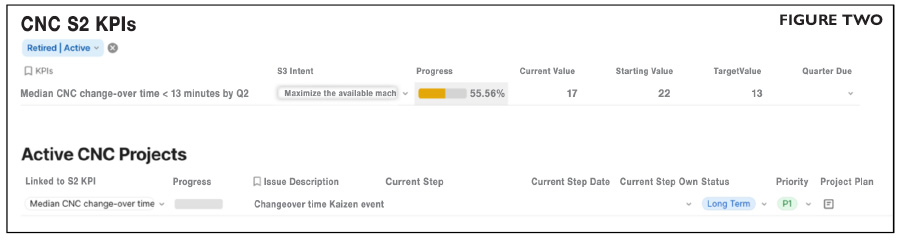

From Figure Two, you can see we set up KPIs (Key Performance Indicators) for each Intent. We do this by asking the question: “What would we measure to tell us if we are moving toward our Intent or away from it?” We also identify specific projects to be executed to drive the KPIs toward their goals.

You can see from these examples that every KPI is explicitly linked to an Intent, and every project linked to a KPI. This creates a direct connection between every role’s KPIs and projects to the Intent of the business.

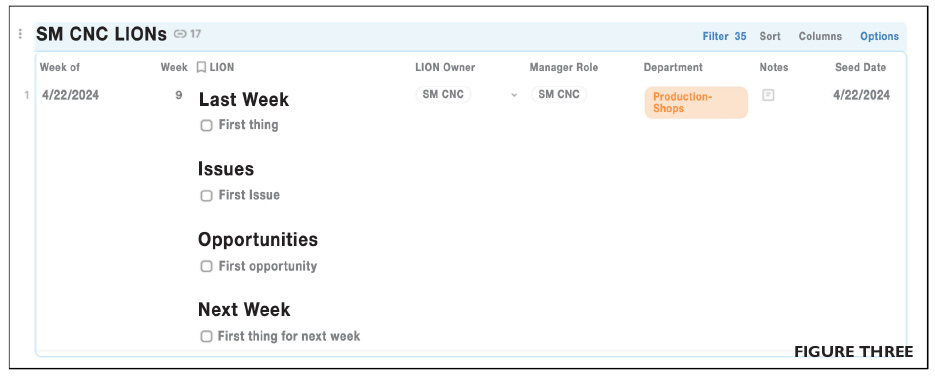

Toward the end of every week every manager meets with their boss (the General Manager meets with their Executive Coach) for a LION meeting to review what was accomplished Last week in moving their projects forward, what Issues they encountered that need to be elevated to the team, what Opportunities they identified, and what their work plan is for Next week to move their projects forward.

Every Monday morning, each team, starting with the General Manager’s team, quickly goes over their plan for the week so that everyone is in tune with what is being worked on, and what cross functional issues need to be addressed to keep the work progressing.

Shops that have implemented the rigor of this system are relentless in their pursuit of the continuous improvement of their businesses. All project work is clearly linked to the business objectives and prioritized. Only three active projects per manager are allowed. We want the businesses we work with to Prioritize, Focus and Finish their project work. There is no “partial credit” in the business world. There is also no credit for doing projects that do not connect to the Intent of the business!

If you would like to align your business and Prioritize and Focus your team’s efforts so they actually Finish projects in a timely manner, Contact us at www.synchronoussolutions.com .

Rick Phelps – Synchronous Solutions