Manufacturing Impacts: Natural Stone vs. Porcelain

Stephanie Vierra

Assoc. AIA, LEED AP BD+C

Vierra Design & Education Services, LLC

Reprinted by Permission usenaturalstone.org

Porcelain is a hardwearing material that is suitable for both indoor and outdoor design projects. Porcelain slabs or tile are often used for kitchen and bathroom counters, flooring, stairs, and windowsills. It is a fairly thin material, typically manufactured to be only ½-inch thick.

The basic ingredients that go into the process of manufacturing porcelain are clays, sands, and different feldspar minerals. Because it contains some natural materials, porcelain is often marketed as a sustainable material. Porcelain is also produced to emulate the beauty and veining of marble. But as you will see from the manufacturing process outlined below, the use of many materials and additives, and the energy intensive processes involved in its manufacturing create a much larger environmental footprint for porcelain than natural stone.

|

|

Left: Porcelain is often printed to mimic the beauty and veining of genuine marble. Photo courtesy of Stephanie Vierra.

Right: Arabescato marble, showing the natural formation and veining present in crystalline marble. |

Manufacturing Porcelain vs. Natural Stone

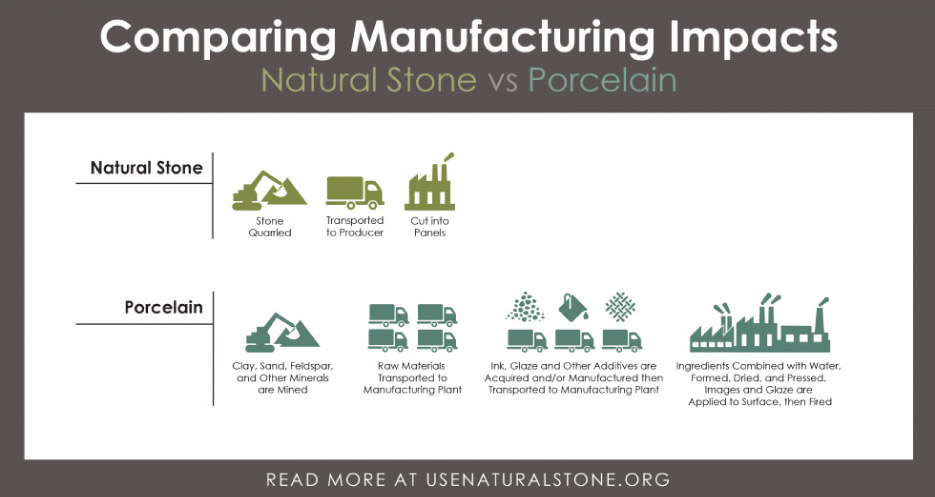

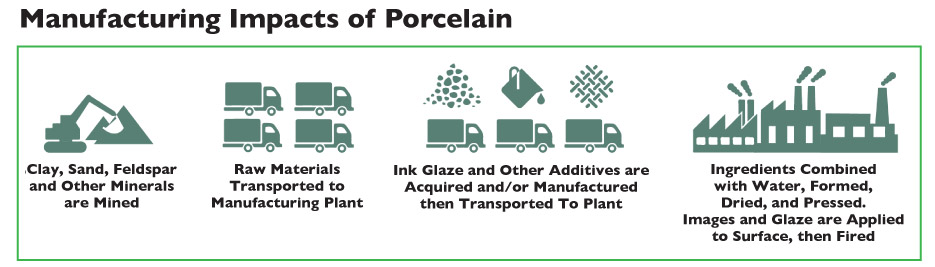

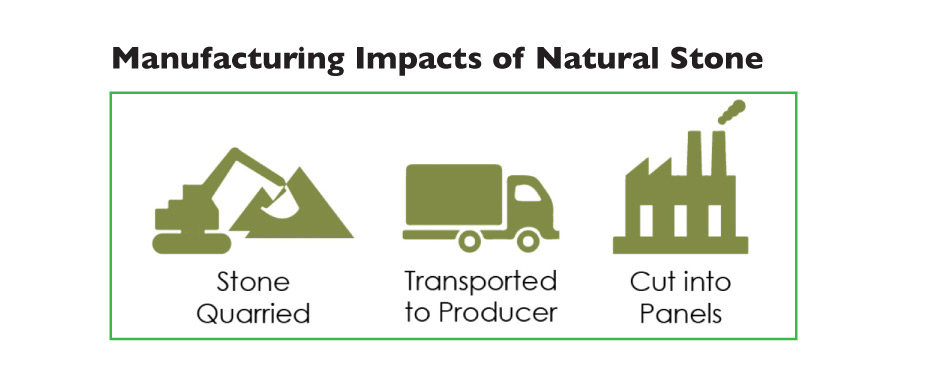

Raw materials like clay, feldspar, and other materials must first be mined out of the ground and then transported to a manufacturing plant. The next step in the process is the intake, storage, and sorting of the required raw materials. Additives such as inks and glazes must also be transported to the manufacturing plant, where they undergo further sorting, mixing, forming, drying, and pressing. Images and glazes are applied to the porcelain surface at this stage. Then, extreme heat is required to fire and glaze the materials into the final porcelain product.

|

|

|

|

|

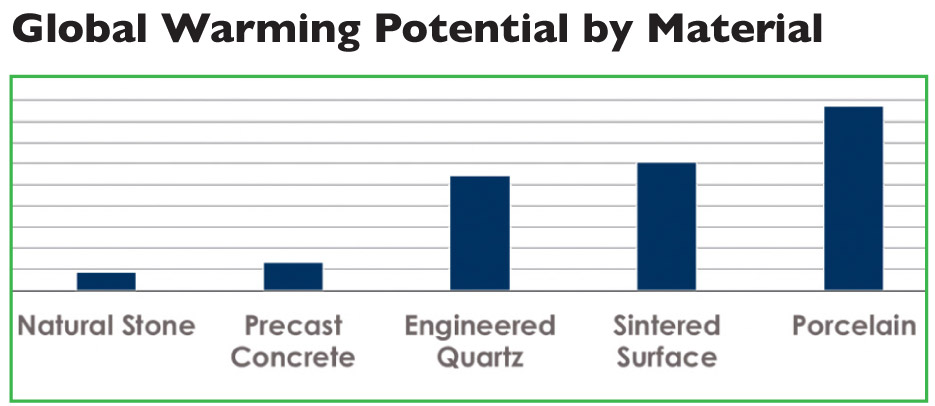

Below: This chart compares the Global Warming Potential (expressed as kg CO2 eq) of the product manufacturing phase (A1-A3) documented in the LCA results published within EPDs, for a variety of products. Data averaged when multiple EPDs were used. All functional units converted to 1 ton. |

|

Sustainability Concerns

From an overall sustainability perspective, natural stone has a much lower environmental footprint than porcelain due to the minimal resources used to quarry, fabricate, finish, and transport it. In fact, it has been demonstrated that porcelain has the highest global warming potential (GWP) among several other building materials. All of the steps in the manufacturing process of porcelain require the use of a lot of water and energy which contribute to a large GWP. The larger the GWP, the more that a given gas warms the Earth compared to CO2 over that same time-frame.

The impacts of these processes have been documented and systematically compared against other materials using the same environmental criteria. This information is a valuable resource when selecting a sustainable material, especially natural stone, for a project.

These characteristics and attributes also make natural stone a great choice when seeking a green building rating certification within the U.S. Green Building Council’s Leadership in Energy and Environmental Design (LEED) or the International Living Future Institute’s Living Building Challenge (LBC). To further advance these issues, the natural stone industry has been working diligently over the years to make continuous improvements in each area and step of the production process. This includes reducing water use, energy use, improving the efficiency of the transportation of natural stone, properly managing and adaptively reusing quarry sites, and many others.

|

|

Halibut Point State Park in Massachusetts is a former granite quarry reclaimed into a public park. Photo by Toby McGuire |

The natural stone industry has created a certification system that determines if a quarry or fabricator meets defined sustainability standards in key areas of importance. This makes it easier to find and use natural stones that meet the standard, simplifying the process of choosing the right material that not only looks and performs well, but also has the least amount of impact on the environment. The standard is also accepted within the LBC, further ensuring its use in sustainable building projects. Even if a natural stone is not yet certified to the standard, the information can be used to vet stone suppliers and ask important questions to help choose the optimal natural stone for your project.

More information is available via the Natural Stone Institute or NSF International.

Stephanie Vierra is a consultant specializing in curriculum development, project management, and research in sustainability and holistic design. This article is part of a series, and will be continued in the April SRG.