Protective Capacity

Ed Hill

Synchronous Solutions

“Murphy lives.” Particularly in a custom maufacturing business, unplanned disruptions will occur. Equipment issues, material issues, people issues, information issues and more will happen in our businesses. Of course, we will strive to minimize attacks by Murphy, but it is unrealistic to expect that we can eliminate all of them. Therefore, we must employ an approach that will recognize that reality.

“Murphy lives.” Particularly in a custom maufacturing business, unplanned disruptions will occur. Equipment issues, material issues, people issues, information issues and more will happen in our businesses. Of course, we will strive to minimize attacks by Murphy, but it is unrealistic to expect that we can eliminate all of them. Therefore, we must employ an approach that will recognize that reality.

Most of the manufacturing science approaches are made for the production of widgets. If you make thousands of the same item (like automotive, printing, electronics, pharmaceuticals, or any mass production industry), then Lean Manufacturing, The Toyota Production System, Just-in-Time, Demand Flow Technologies…are for you.

But if you are more of a “job shop” business in which:

- Every order is unique from every other…or

- Much of your raw material is a product from nature…or

- Your business is reliant on skilled employees (rather than full automation) to get the work done…or

- You work directly with the ultimate consumer who is quite likely to change his/her mind on a whim…

Then, you need a manufacturing system that is designed to accommodate those realities.

The key elements of the Synchronous Flow system are processes designed to deal with the inevitable appearance of Murphy. It is called Protective Capacity.

“Required” means that Protective Capacity is not an option. It means that you must plan for the absorption of the inevitable disruptions caused by normal occurrences every day:

- Machines will break down.

- Materials will have defects.

- Workers will be absent.

- Customer information will change.

Unless you operate a system that deals with these certainties, you will constantly be reacting to their effects. Dealing with those realities in a proactive manner is a much better approach.

Protective Capacity is also called an unbalanced system. Imagine that…we actually seek to remain unbalanced rather than operating a balanced system. A balanced system will never reach its designed productivity because there is no accommodation for “Murphy.”

Balanced capacity systems always result in the following undesirable effects:

Balanced capacity systems always result in the following undesirable effects:

- Nameplate capacity is never achieved

- Expediting is a common tactic

- Lead times are longer than desired

- Chaos is high

- Overtime might help, but…

– It is expensive

– It has diminishing returns

– It is usually reactive in nature

– It can create a dependency

– It adds to the chaos.

Sound familiar? Given all that, there must be a better way. And there is.

The truth is that all systems are inherently and naturally unbalanced. If excessive inventory and long process times are present in your system, Protective Capacity already exists. There is no need to hire people or buy equipment to create Protective Capacity. It is all about how you manage the capacities that currently exist.

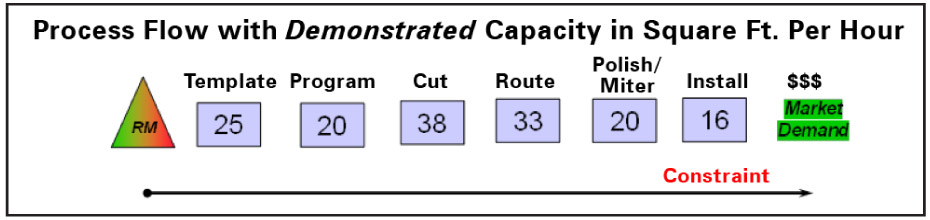

Routinely, managers and supervisors erroneously take actions that move the system back to a balanced capacity state resulting in the undesirable effects just listed. While every company is unique and capacities at each resource step are highly variable, the following is typical across the industry.

In the Process Flow diagram, the capacity of the system is sixteen square feet per hour. “A chain is only as strong as its weakest link.” While every other process step has more demonstrated capacity, the system is limited by the capacity at the system’s constraint. The constraint can be anywhere in the system. Our process will measure demonstrated capacity to identify the true system’s constraint.

It is important to note that processes having Protective Capacity cannot work at full capability throughout the day. Doing so will only create piles of excess and unneeded inventory. Conversely, workers there should produce with Roadrunner Mentality. Like the Warner Brothers cartoon, roadrunners have two speeds: Wide open and stop.

This means that they should work at full capacity until they have met the needed schedule and then they should stop on that operation. They should, like a Roadrunner, move to another location in the process that needs their productive capacity.

Protective Capacity can be abused in two ways:

- Process steps can be allowed to produce beyond the demand creating unneeded work-in-process inventory. The capacity used to produce that excess inventory is no longer available to address recovery when Murphy attacks.

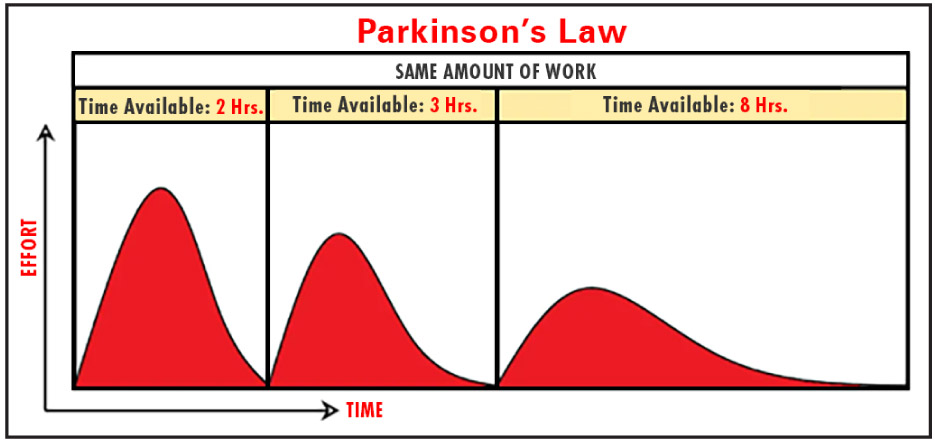

- Parkinson’s Law: “Work expands to fill the time available.” Without effective management, six hours of work can be expanded to consume eight hours of time. In other words, the same amount of labor content can be spread over more time by simply reducing the effort expended to do it.

This is a management issue. Allowing the work to be stretched to consume all available time or allowing any process step to produce excess inventory will eliminate the availability of Protective Capacity when it is needed to overcome Murphy.

In the Synchronous Flow approach there are three types of Capacity:

Productive Capacity is the pure capacity required to meet the projected market demand. This is the minimum needed to satisfy orders and has no accommodation for Murphy.

Protective Capacity is productive capacity plus an accommodation for Murphy. The accommodation for that variability is calculable, meaning that where there is little variability there is little need for Protective Capacity. Where there is high variability, there is need for more Protective Capacity. With adequate records on production and variability, this can be planned accurately. Protective Capacity does not mean higher costs. This cushion of additional capacity is essential to meeting the market demand given the known levels of variability (aka Murphy). Business is all about creating value (Throughput), not just reducing costs.

Excess Capacity

This is the amount of capacity beyond the needed amount to meet the demand including an accommodation for Murphy. Excessive capacity means excessive costs. Therefore, when you know it exists, you will need to plan the utilization of these resources to assure adequate control of this excess cost.

If you have read The Goal by Dr. Eli Goldratt, you will recall that the primary principle of Synchronous Flow is that non-constraints must maintain enough protective capacity to maintain a consistent and smooth flow of material and information throughout the system. The entire business system must support the control point (install) and every other resource must maintain a level of Protective Capacity so the control point can operate at a consistent pace. Protective capacity is not excess capacity, rather it is the required capacity that will make the entire system work.

Non-constraints, by definition and design, cannot be working at full capacity throughout the workday. Non-constraints need only to produce enough to maintain the desired buffer to protect the control point.

A common approach of balanced systems is to keep everyone busy all of the time with no wasted capacity. This is a fallacy. Balanced systems will not produce the desired results and, in fact, are a practical impossibility. Maintaining the appropriate levels of Protective Capacity will produce desired results and will also reduce the chaos that afflicts the attempts to create balanced systems. Improving the quality of life for your employees is a valuable bonus for any business.

An important principle of Synchronous Manufacturing is that you should not focus on balancing capacities but, instead, focus on synchronizing the flow of both materials and information throughout the overall process. Like water flowing down a mountain river, the orders should move at a consistent rate. The boulders that interrupt that river flow are not unlike the “Murphy” events that interrupt your process flow. The water always finds a way around those boulders. Your managers need to do the same thing to address the “Murphy” events. To do that, they will need a planned level of Protective Capacity to absorb that variability.

An important principle of Synchronous Manufacturing is that you should not focus on balancing capacities but, instead, focus on synchronizing the flow of both materials and information throughout the overall process. Like water flowing down a mountain river, the orders should move at a consistent rate. The boulders that interrupt that river flow are not unlike the “Murphy” events that interrupt your process flow. The water always finds a way around those boulders. Your managers need to do the same thing to address the “Murphy” events. To do that, they will need a planned level of Protective Capacity to absorb that variability.

Without an appropriate amount of Protective Capacity, the ability to create value Throughput ($T) will be negatively impacted. As the schedule begins to deteriorate, the inevitable result will be more overtime and growing chaos. The reality is that ultimately, all manufacturing systems are unbalanced. Given that, it is a much better strategy to plan for that reality than to fight it.

We have proof that attempting to maintain a balanced capacity system where each resource operates at maximum efficiency would create high inventories, long lead times and poor delivery performance, all of which are unacceptable in today’s manufacturing world.

An unbalanced manufacturing system may seem odd, but the results of this strategy can be outstanding.

Synchronous Solutions, LLC has developed programs specifically for the stone processing industry. For more information, contact Ed Hill at (704) 560-1536, email EdHill@SynchronousSolutions or visit the website www.SynchronousSolutions.com