Communication and Accountability

Both are Essential for an Effective Business System

Ed Hill

Synchronous Solutions

In my work over the years with companies in myriad industries, I have noticed a common issue that affects virtually every organization. People tell me:

In my work over the years with companies in myriad industries, I have noticed a common issue that affects virtually every organization. People tell me:

- “We just don’t communicate well. I never know what’s going on. Sometimes I find out things after it is too late to avoid serious issues.”

- “We don’t hold people accountable. We keep making the same mistakes and fighting the same fires day after day.”

According to Merriam-Webster, communication is defined as a process by which information is exchanged between individuals through a common system of symbols, signs, or behavior.

Note that the definition uses the terms “process” and “system.” This is important. Certainly between close friends and (perhaps) married couples, some communication occurs without words, either verbal or written.

Note that the definition uses the terms “process” and “system.” This is important. Certainly between close friends and (perhaps) married couples, some communication occurs without words, either verbal or written.

In the military world, communication systems are set using silent hand signals, for obvious reasons.

But, in the business world, we need clarity. We need absolute certainty that the message has been effectively communicated and understood. It is important to note that communication has occurred only when the receiver understands the message clearly. As such, the burden of communication is on the sender, not the receiver.

Accountability is defined as an obligation or willingness to accept responsibility or to account for one’s actions. Key words in this definition are obligation and responsibility. Consider this example:

If Bob works for (reports to) Tom, then Bob would be responsible to do what Tom tells him to do. It would be Tom’s job to hold Bob accountable for doing those things. The very first time Tom does not address something Bob has done incorrectly, then the clear message is that Bob is no longer responsible to follow Tom’s direction. Bob is no longer accountable to Tom. Moreover, every other employee who witnesses this situation is also no longer accountable to Tom either. Tom has just lost all management authority. It really takes only one time of bad accountability management to destroy a manager’s usefulness.

Most companies have daily production meetings designed to discuss the current issues that should be addressed. These daily meetings usually concentrate on responses to problems that have already occurred. They are reactive in nature (aka Firefighting). The situation is that the problem already exists, and the objective is to determine what must be done to correct it. They also often evolve into a “finger pointing” session as people seek to find someone to blame for the problem.

The stone processing industry is mostly a custom manufacturing challenge. Virtually every order is unique. Each one must be designed and manufactured as an individual process and different than every other. Unlike other industries like automotive and printing that produce thousands of the same order, the stone industry must manage a system that is not able to gain the efficiencies of mass production. Moreover, this individual production environment opens the door for an infinite number of single issues (aka attacks by Murphy). If a company seeks only to address these frequent issues after they occur, then you are doomed to live a life of “firefighting.” That is no fun.

There is a better way.

There is a better way.

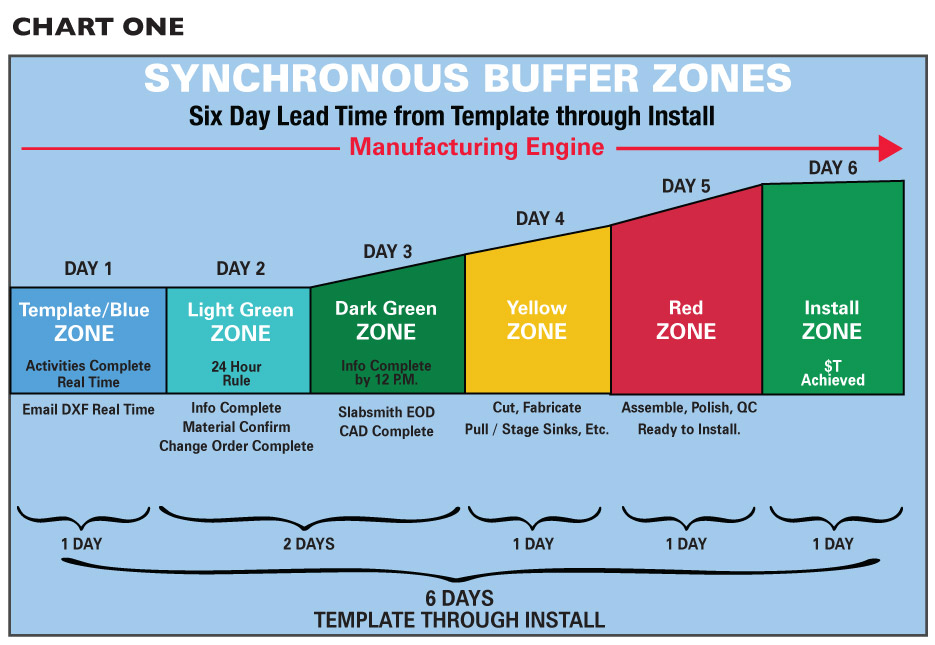

A system of proactive management is possible. Consider Chart One. Buffer Management is the process of addressing identifiable issues before they become a crisis. This is done by analyzing the status of all jobs each day relative to the day they are to be finished (installed or shipped). If a job is not in the zone that it should be each day, corrective (and preventative) steps should be taken to get it back on track quickly. This proactive action is much better than crisis actions after the problem has manifested.

Three important things must occur in each case of an identified issue with effective Buffer Management behaviors. The key is that this is done before the issue becomes a crisis by detecting the cause at its origin.

- The issue must be defined. This includes the job name and/or number and a brief statement of the actual problem.

- The core cause of the issue must be identified. This is the most important (and most difficult) step. We need to know what happened or didn’t happen to cause the problem. We do not want to know how or why the problem occurred. Very importantly, we do not want to discuss who created the problem. If the process ever deteriorates into a “blame game,” then the process will ultimately fail. People participating in the process must know that they can be fully honest and forthright in their reports without fearing that blame will be assigned.

- One person should be assigned as the “owner” of each issue identified. This is the person who will be held accountable for its resolution. He/she may involve other people, but this is the go-to person on the issue for resolution. At the next Buffer Meeting, this is the name to be called for the report on the resolution of the issue assigned. Resolution means that the problem has been addressed and that the job is now in the correct zone for completion on time.

By making a follow-up note as the first agenda item on the Buffer Meeting the next day, a firm accountability process is assured.

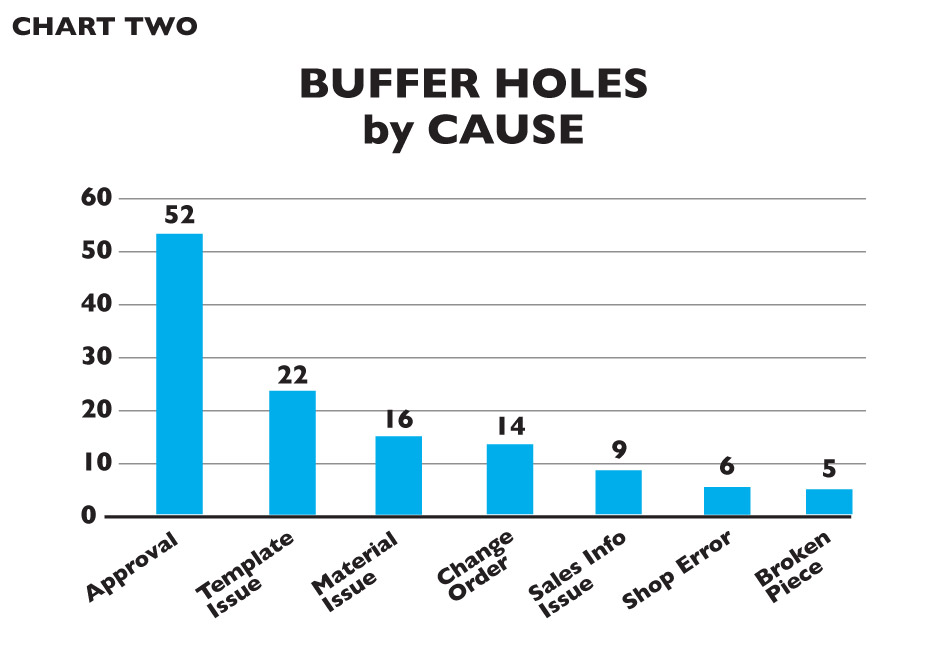

At least once a month, the logbook in which all the Buffer Management data has been collected should be statistically analyzed. This information is now produced automatically by creating a graphic Pareto Chart (aka “tall tent pole”) indicating the most common and chronic core causes that occurred during the recent period. Formal assignments are then made to proactively address each of the assigned projects with the goal of preventing their reoccurrence.

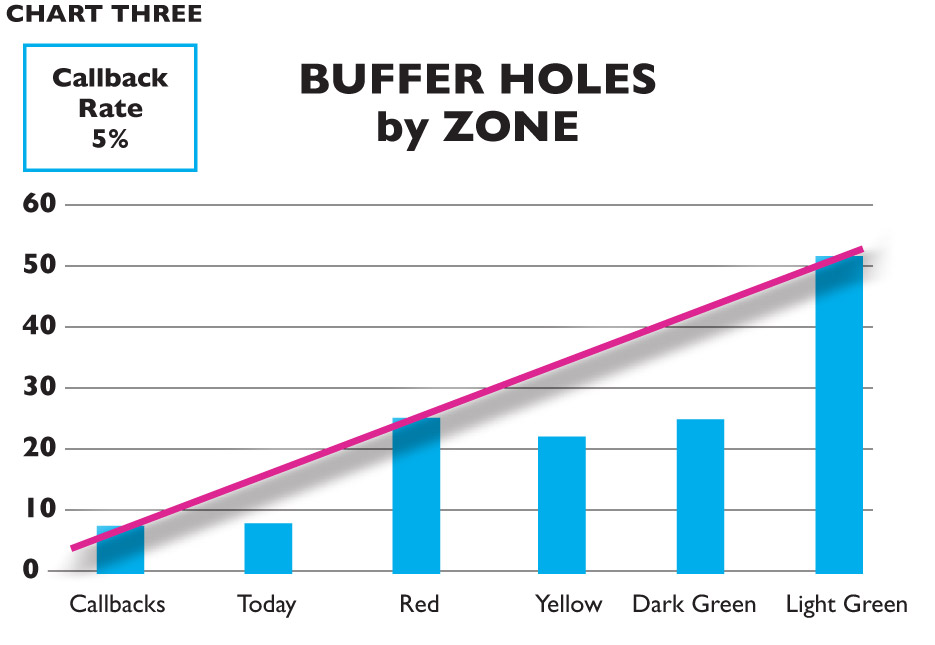

In Chart Three, the same data is presented in the “Buffer Holes by Zone” relative to the Synchronous Buffer Zone diagram. In this chart the bars indicate the location of the issues recorded during the month. We accept that there will be issues occurring in a custom fabrication business. But we desire those issues to be identified early in the process before they can become a crisis right before installation. The red line indicates the desired slope of the issues to be recorded. The Callback Rate box indicates the percentage of all jobs that required an unplanned trip to the jobsite to correct a problem.

Identification and tracking of inevitable issues (Communication) and daily follow up on those issues toward quick resolution (Accountability) is the essence of proactive management.

These are the fundamentals of an effective processes to achieve both communication and accountability. There are many more details of the approach, but this is the basic outline. It takes diligence to the process and consistent leadership. Done right, this will transform your company.

For more information on the Buffer Management and the Synchronous Flow process, contact Ed Hill, Synchronous Solutions, LLC, 704-560-1536. Visit www.SynchronousSolutions.com .