Artisan Group Member Fox Marble Consolidates California Facilities

Peter J. Marcucci

Photos Courtesy Fox Marble and Evolv Surfaces

Most of us can honestly say there was widespread disruption to business conditions in 2020. One trend the SRG noticed is that where shops were able to, they took the downtime to complete needed safety and production upgrades and repairs. Looking back at some of the shops we visited in the past two years, we wondered what changes they had experienced.

It was just a year ago that we featured Fox Marble, one of four divisions of a group of stone industry-related companies, located in San Francisco, California. Fox Marble was created by Charley McLaughlin over three decades ago to serve a demographic wanting custom fabrication for their homes. As the company grew, it expanded its output, divided its services, and grew its markets to the point of over one quarter of California and to the powerhouse it is today.

Fox Stone Care, a second division, is a very successful unit, serving a huge swath of clients from San Francisco and beyond in need of repairs and maintenance.

Evolv Surfaces, a third division, also located in San Francisco at the time, is a materials distributor that sells to distributors throughout America, as well as directly to west coast fabrication shops. The company is a combination showroom/warehouse facility well known for its sintered materials, such as Neolith and Diresco, and its first-quality natural stone materials imported from around the world. This prolific division was slated to be uprooted many years ago, and was newly transplanted in Berkley, California just a year ago. It is happy in its new environment, and is doing just fine.

Fourth and finally, is Fox Hensley, a 50,000 square foot facility that produces custom fabrication. This division was and still is located in Richmond, California, a location that would soon see two of its sister divisions under the same roof.

|

|

Above, left: Production by the Fox Marble Custom division is highly automated, but sometimes there’s no mechanical substitute for hand-finishing a project to perfection. Above, right: A 100,000 square foot building now houses the three divisions including ample production and admin space. Other facility upgrades include a 260 kW solar generating system on the roof, a state-of-the-art ventilation system and a new water treatment system. |

The Risks Versus Benefits of Moving

In early 2019, the writing was on the wall that a move was needed. Profits were good, but expenses and regulations were excessive and growing. The decision was made to sell the existing property and implement a move that would take seven months, recalled Founder and President Charley McLaughlin. “It was an opportunity that we took to make some much needed changes and reorganization. San Francisco is in deep trouble. The city doesn’t really care about businesses, unless you are a sales force or a Microsoft. We were paying $70,000 a year just in city wage taxes, and for what? Additionally, our labor force couldn’t afford to live there. Richmond is more business-friendly, and the labor force here is much more conducive. So, those were our primary reasons.”

By late 2019, the stage was set, and the logistics of moving were in place, but they hadn’t fully finished the sale of Fox Marble’s property to consummate the move. Luckily, by early 2020, the sale was finalized, and the transition could now begin, continued McLaughlin. “We purchased the 5.4 acres that Fox Hensley had been leasing in Richmond, and spent several million dollars upgrading the building and the electrical system, as well as installing a 260 kW solar generating system on the roof. We are now fully up and running in the 100,000 square foot building. Fortunately, during the move, the home improvement business remained viable. I don’t take any credit for that. It was just good fortune at the time. But the hospitality industry and the restaurants at the time – Oh, my goodness! So we were really fortunate and blessed.”

According to McLaughlin, the divisions did lose some people during the transition and to the COVID shutdown. They also did not bring some management staff, due to some much needed reorganizing. Not major, but some did occur, said McLaughlin, adding, “When you go into combat, you never know how people are going to react until you’re in the thick of it, and we were in the thick of it, especially in spring of last year. Fortunately, because we have such a good leadership team, I didn’t have to personally spend that much time coordinating things at a higher level. Our V.P. of operations, our controller, all the administrators and all the team leaders at the management level just rolled up their sleeves and did it. The cream rose to the top and really flushed out those that weren’t ready for prime time. It was wonderful to experience that. These are the leaders who will take the company beyond my days. They did an amazing job. I can’t say enough.”

|

|

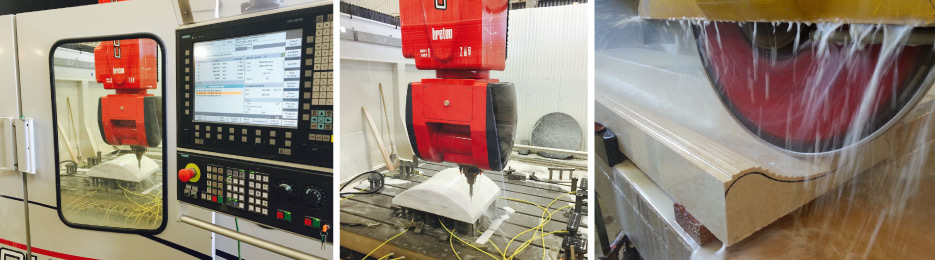

Above, left and center: With its 3-D capabilities, the Breton dual-table 5-axis CNC is a workhorse for Fox Marble Custom production. Above, right: Their BACA Robo Sawjet step-cuts a fireplace surround. |

|

|

Above: White Macaubas quartzite bar top features a faceted miter edge. Produced and installed for Avow, a restaurant in Napa, San Francisco, all the table tops feature the White Macaubas quartzite. |

|

|

Black Moon marble fireplace surround fabricated by the Fox Marble Custom division, which excels in fabricating large, 3-D projects |

A New Location, New Branding and More

With all production now under one roof, the situation still required that all companies continue to be independently managed and accounted. In other words, Fox Marble (now Fox Marble Production) and Fox Hensley (now Fox Marble Custom) are all separately staffed and supervised by separate teams. However, all divisions are overlooked from a high level by division CEOs and McLaughlin.

As for production machinery, both McLaughlin and management felt the best thing to do was to liquidate the old waterjets, bridge saws and CNCs, and stock the new facility with all new equipment… sort of. “We brought in new BACA robots, a Breton CNC and other new equipment. We did, however, bring one machine from the old shop with us. It is a Breton 5-axis, dual table CNC. I didn’t want to do that, but the team talked me into it, because Fox Marble Custom produces some very intricate and expensive 3-dimensional products. It was worth it, though, and the machine was still relatively new.”

Additionally, safety and efficiency have always been hallmarks of the Fox divisions, so while they were at it, their new production line was also outfitted with a state-of-the-art ventilation system and a new water treatment system, said McLaughlin. “All of this new equipment really upgraded and streamlined our processes as well as created a safe environment.”

|

| Above: Fox Stone Care division has been very successful offering diverse services to residential and commercial clients in the Greater San Francisco Bay Area. |

|

| Above: Residential project in Las Vegas includes a custom game room bar, great room fireplace surround, and interior Neolith Flooring; on the exterior, the overhang cladding and facade, and an infinity pool facade also feature Neolith. |

|

|

Above, left: Neolith cladding on the Las Vegas boutique Feature storefront. The store interior also uses a coordinating Neolith wall cladding. Above, right: Vent cover produced with their Breton CNC. |

Closing Words by McLaughlin

“Natural stone is never going to go away. Granite seems to be waning in popularity here, but classic marbles and quartzites are always going to be around. We have 35 years of sourcing from the best suppliers in Italy, Spain and Brazil, so we are very well positioned with natural stone. Our growth will continue, and every division now has a new budget for 2021. The only division that will not grow, and it’s no surprise, is Fox Marble Custom. Nevertheless, Fox Marble Production, Fox Stone Care, and Evolv Surfaces all have very healthy growth budgets, and I see no reason why they’re not going to accomplish their budgets.

“Furthermore, even though Fox Marble Custom is still the least profitable, the manufacturing volume has grown, because we’ve taken on a few other national accounts. So the custom work is always going to be there. It’s our core business, and how we started, but it’s getting harder and harder to stay in the black, no matter how much we charge. You can have the best labor and the best designs, but the coordination it takes is really, really difficult. The barriers of entry are high, and the profit margins are low. As for Fox Marble Production, the competition is harder, but it’s okay, because the stone work here is growing in leaps and bounds and our manufacturing is going gangbusters, and we are happy.

“Moving our divisions was an amazing accomplishment, especially during a pandemic and being shut down for two months during March and April, but somehow we did it, and it’s working out wonderfully.”

For more information please visit www.fox-marble.com .