The Goal

A Process of Ongoing Improvement

Ed Hill

Synchronous Solutions

What is the goal of your company?

- Producing quality products?

- Delivering excellent customer service?

- Providing short process times?

- Maintaining a pleasant work environment for your people?

- Sales growth every year?

- Lower costs?

- Survival?

The fact is, your company is in business to make money. If you were excellent at every item in the list above, but you were not profitable, you would go out of business. Your business should be organized to “make more money now and in the future.” Earn a reasonable profit in the present conditions and set your company up to make more money in the future. It is all about continuous improvement. This is the message in The Goal, a book written by Dr. Eliyahu Goldratt, which in my opinion is one of best business books ever published.

The Goal is written as a novel and explains the business approach called The Theory of Constraints (TOC), now known as Synchronous Flow. It is the story of application of the TOC principles to transform an underperforming company to an excellent one. Moreover, it is the story of how continuous improvement can be a systematic approach to business management.

If you haven’t read this book, I encourage you to do so. If you haven’t read it recently, I encourage you to read it again. It is available from any book seller in hard copy, digital or audio formats.

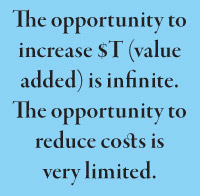

One of the key principles of Synchronous Flow is Throughput Accounting, which is a simple, yet extraordinary, way to look at a company’s finances. It focuses on revenue generation, not product costing. As such, it focuses on the positive potential of a company (the generation of wealth) and not on the reduction of costs. That is not to say that good stewardship of resources is ignored. It’s just that the focus is on generating revenue, not cutting costs.

An important aspect of Throughput Accounting is that the metrics are derived using the same data as in the existing cost accounting system. This means that there is no investment in additional accounting software or resources. No additional entries have to be made. The numbers are simply calculated in a different way and presented in a different report format. The bottom line is always the same in either accounting system.

Throughput Accounting focuses on creating more profit now and in the future

There are three important metrics regarding “making money.”

- Net Profit (NP) is an absolute measure. If your income exceeds your expenses, you made money. Earnings before interest, tax, depreciation and amortization (EBITDA) is a common measure of a company’s operating performance.

- Return on Sales (ROS) is a relative measure. Making $100,000 on ten million in annual sales is only a 1% ROS. Not very good. In fact, a privately owned company should expect at least a 10% ROS every year.

- Cash Flow is a survival measure. If you have enough cash flow, it may not be an important metric. If you don’t have enough cash flow, it is the only important metric.

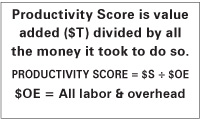

Throughput (expressed as $T) is the rate at which a company earns money through sales. It is the measure of value added. A company buys raw materials, transforms them into finished products and sells them to their customers. Throughput is the measure of value added due to the transformation of raw materials into finished products. The formula for Throughput calculation is:

Throughput = Sales – Truly Variable Expenses

Truly variable expenses (expressed as TVE) are those outflows of cash associated directly with a specific product or job. They are “variable” in that changes in TVE are directly associated with changes in sales.

Typical variable expenses are:

- Raw materials

- Transportation costs for the raw materials

- Outsourcing (farming out manufacturing to another company)

- Sales commissions (paid per sale, not per time period)

If all four were active, the formula for $T would be:

Throughput = Sales – (raw materials + freight + outsourcing + commissions)

The continuing objective should be that Throughput is always trending up.

$T Scheduling

Rather than using square feet, which is often not reflective of actual labor content (see The Art of Scheduling in the February 2019 edition of SRG), we use $T as the primary metric for scheduling. Daily “buckets” are filled to a predetermined amount to meet the market demand and to achieve the financial goals of the company.

Your vehicle runs best with the proper mixture of gasoline (fuel) and air (oxygen). If that mixture is not correct, the engine will not run well, if at all. Scheduling is much the same. A good schedule requires the proper mix of volume (how much) and velocity (how fast). The volume should be “Level Loaded” using $T to assure the labor content is about the same day to day. A level load by itself will increase business productivity. The velocity, or time allowed, must be controlled too. A desirable and common process time for the countertop industry is one week from template through install. Template Monday; install the following Monday. A good schedule will allow the same process time for all jobs. In fact, scheduling jobs with different process times will cause manufacturing disruptions and chaos. The best schedule is one that is level loaded and all jobs planned to flow at the same pace.

$T Tracking

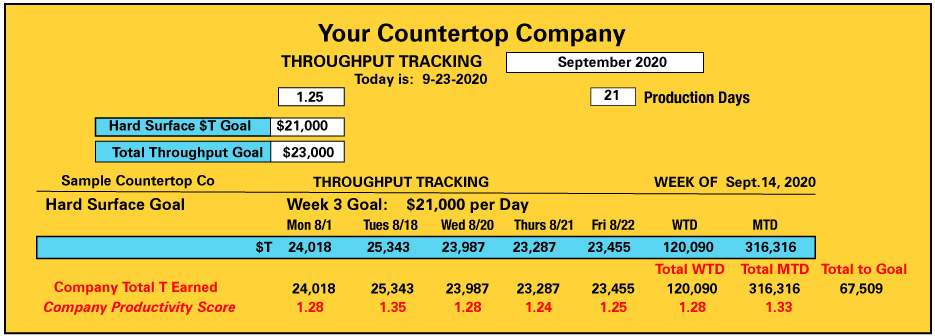

The best business performance is one that creates a plan for action in advance of each month. You should know how much value added ($T) you need per day in order to make a given level of profit. You should set up these goals for your scheduling department to load that amount of $T for each product line each day of the month. And, you will need to track this performance plan every day to assure that the goals can be met at the end of the month. Chart One is a daily $T Tracking Report indicating the status to the monthly goals.

In this example, the daily $T Goal is $23,500 with a Productivity Score Goal of 1.25. The current score is 1.33 which is $67,509 ahead of the goal so far, that month.

Buffer Management

The fundamental behavioral change in Synchronous Flow is Buffer Management. The purpose of the daily Buffer Meeting is to identify and record buffer status issues and assign responsibility to address them. The meetings are held once per day at a designated time and place for a maximum of 15 minutes. Everyone is expected to be on time and prepared to discuss the status of the Buffers for which each is responsible.

The status of WIP orders is reported and any issues are identified including the Core Causes of each. All actions items and person responsible are communicated. At the next meeting the following day, accountability for previous assignments is discussed. This is the essence of proactive management.

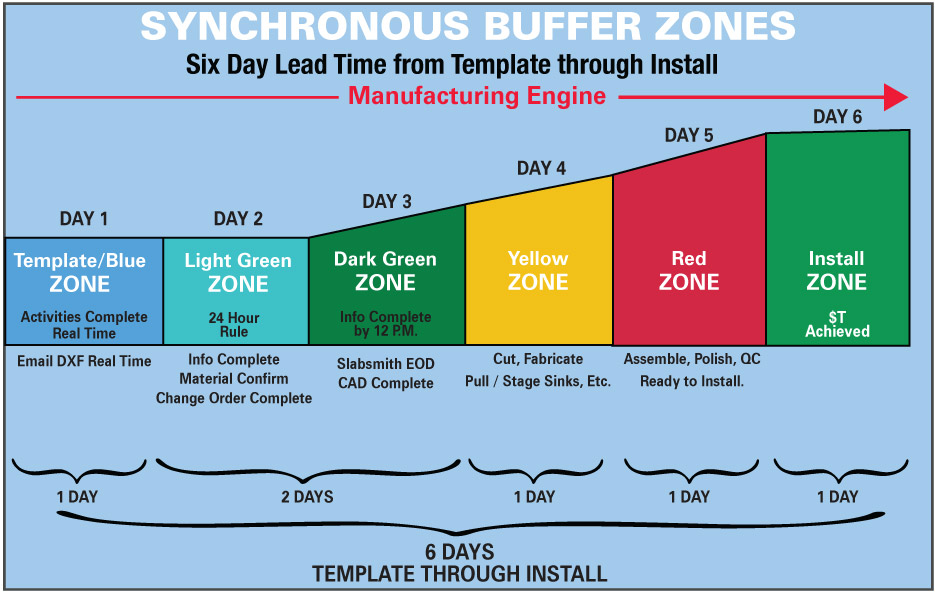

Buffers are color-coded zones covering the entire process flow from sales through installation and income collection (Chart Two). Normally, each Buffer Zone represents one day of process time. Buffers are measured in time rather than volume. The total time for all Buffers equals the time planned for processing from Template through Install. The standard process time we advocate is one week.

Buffers are like shock absorbers or insurance policies for the system. The primary focus of the Manager becomes controlling the Buffers more than efficiencies of the people. This is all about proactive steps to prevent crisis.

The concepts of Synchronous Flow are explained in a clever manner in The Goal. I encourage you to read it and visit www.SynchronousSolutions.com to learn how it is applied to the countertop industry.

For more information on continuous improvement and the principles of Synchronous Flow, contact Ed Hill at Synchronous Solutions, www.SynchronousSolutions.com or call 704-560-1536.