EasedEdge Software: Born & Raised at Sarto Countertops

Peter J. Marcucci

Photos Courtesy Sarto Countertops and EasedEdge

It has been almost two years since EasedEdge software made its public debut, and by all indications is exemplary of what software designed to create synchronicity should be. What is synchronicity, you ask? Well, in the context of production, it’s the coordination of events that result in a smoother and more productive work flow from beginning to end. (Editor’s note: please see Creating Synchronicity with EasedEdge Software in our September 2020 issue, for Ben Strong’s commentary on EasedEdge’s development and features.)

|

|

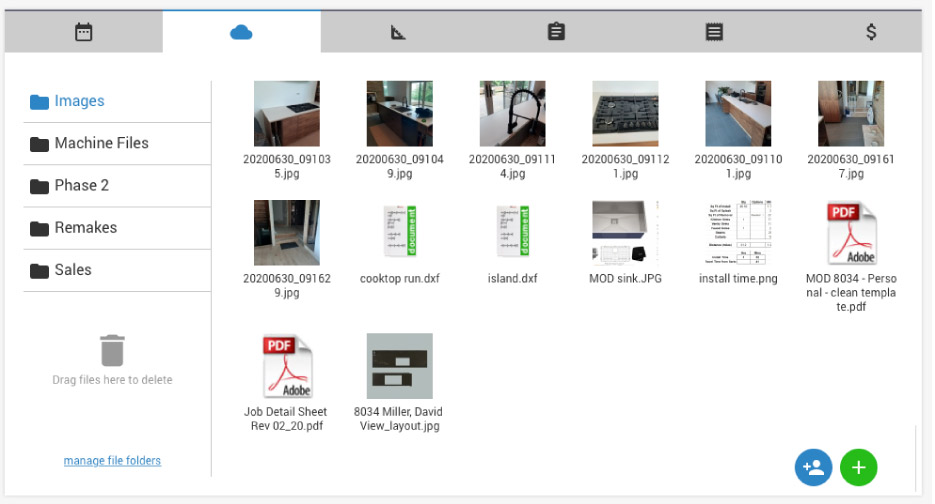

Online resource sharing and file storage within the EasedEdge interface enable every member of the team to quickly access details about a job. “Everyone is on the same page with Job plans, from initial layout and materials to installation,” said Ben Strong. |

|

|

|

From left: Robert Wiemann and Guiseppi Vanderputten of Sarto Countertops developed EasedEdge production and communication software for use in their own growing shop. |

Going with the Flow

Developed by software engineer Ben Strong and the owners of Sarto Countertops, EasedEdge was created, tested and proven in real world conditions. Sarto Countertops is fairly new to the fabrication scene, and is owned by Guiseppi Vanderputten (Sep) and Robert Wiemann. It is staffed with forty professionals throughout all departments, and features a shop outfitted with a full array of Park Industries machinery, including a Saberjet waterjet.

The shop is well managed, well stocked with direct imported slabs, and has had an earth-shattering growth rate averaging 150 percent per year, but it was missing one thing, explained Sep Vanderputten: comprehensive client/employee communication.

“Our philosophy from the get-go was to make ourselves replaceable, and to step away and expect everything to get done as if we were there. Neither my partner nor I wanted to be so key that we had to be here running the company. However, the first couple of years in business, most of the information was in my head, but doing business this way became less and less doable as our volume grew.

“We eventually began using simple tools such as a wall calendar and Dropbox, as well as QuickBooks, but as we got busier and busier, even this wasn’t enough, especially with our philosophy about wanting to be replaceable. So the first thing we did was to pull the trigger on some industry-specific software that’s been around for a long time, but because of our growth, we weren’t very happy with it at all. It did not accomplish what we wanted, which was a robust and comprehensive system that was very easy to use, and when you put those wants together, none of the available software actually fulfilled that. You could get complex and robust, but it was hard to use, or you could get simple, but it didn’t function the way we wanted it to.

“Fortunately, though, we were blessed in a way, because my partner had done a project previously with a software developer, and in our third year in business, he concluded that using the available software was ridiculous, and because of our digital production process we should just develop our own. We were a young company, and not set in our ways, unlike so many older companies that have had a way that’s worked for them for many years. But this industry is changing so rapidly and, again, being so new in the industry, we were excited to be able to develop software.”

The Advent of EasedEdge

Being so busy with a fledgling but growing company, Sep and Robert put the idea of home-built software aside, at least for a little while, until it became an absolute necessity by the beginning of year four. It’s also when they got together with software engineer Ben Strong, recalled Sep.

“The biggest advantage to us building this software was because we were fabricators and we knew exactly what we wanted, and as we grew in leaps and bounds and our needs and wants evolved quickly, we felt that software had to do that also, and not hinder our growth. Robert and I are very flexible and very quick to realize that if an idea doesn’t work, we will change it, revamp it or scrap it! At no point are we ever set on what a good idea is, and not afraid to admit when something doesn’t work. Our industry is unique, because not only do we have to estimate and invoice, we also have to keep track of inventory, template, fabricate and install while tracking the job from start to finish. So there’s a bunch of different departments and lots of information, and being able to put all that information in one place minimizes mistakes.”

It took about eight months of development before EasedEdge was rolled out within the company and all departments were switched over. According to Sep, it immediately made a huge, huge difference.

|

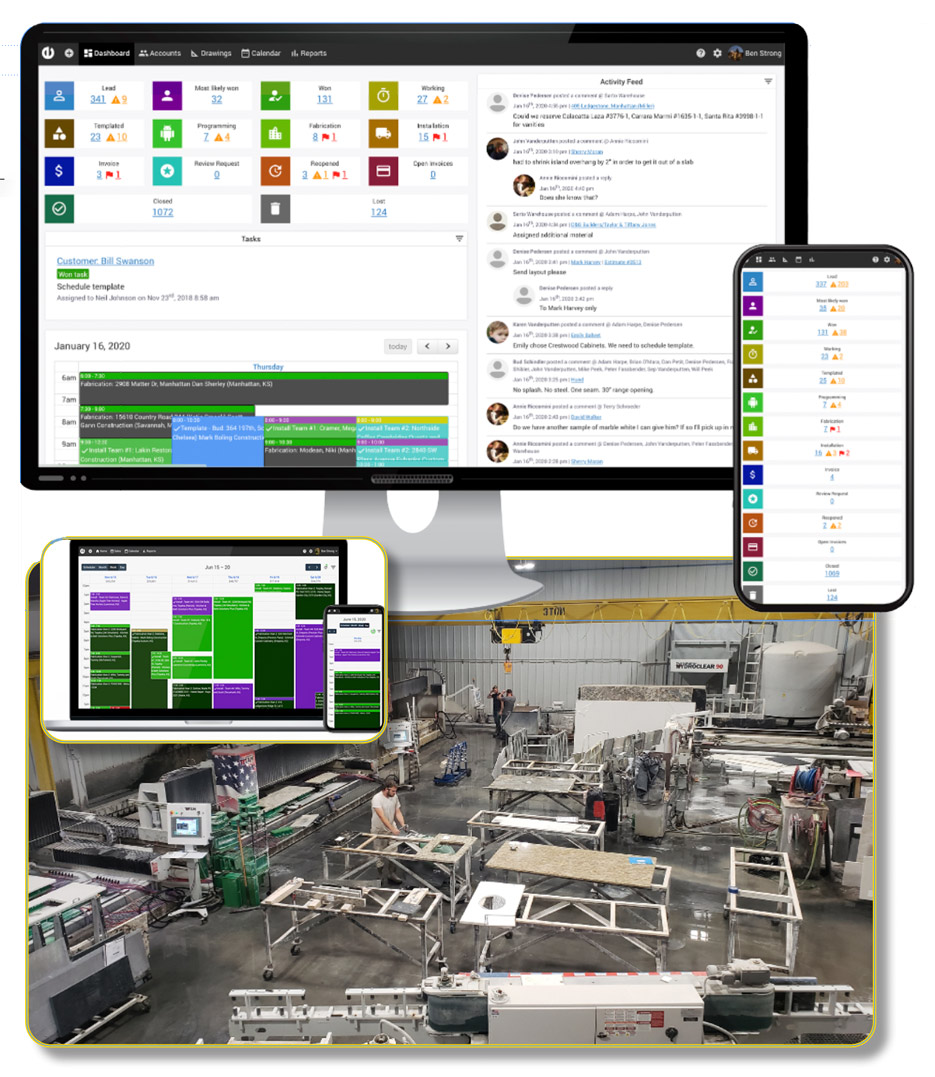

| Ben Strong: "When you launch the app, the first thing that comes on screen is the dashboard – a snapshot of where all the jobs are. At a glance, you can see how many jobs are on leads, how many are getting old, and you also can see how many jobs have alerts or holdups.” Inset: This screen shows a typical week of jobs scheduled for install. If a customer calls or emails wanting to know when their kitchen is going to be installed, the person scheduling does not have to walk out to the shop to find out what stage a job is at. That information is just a mouse click away. |

|

|

Sarto Countertops currently has about 40 employees, throughout all departments. All are connected through the EasedEdge portal, whether on desktop or their smart phone. |

|

“Being able to consolidate everything in one place was key for everyone to know what they needed to do next. This feature alone is the biggest thing that sets EasedEdge apart from other software, and when combined with other information, has allowed us to get our CNC and waterjet production to its peak and continue to grow our bottom line at a 150 percent per year pace. Furthermore, it’s allowed me and my partner to reach our goal of us not having to be a daily part of the process, because we built the whole process into the software. No one needs to pick my brain for information anymore, because EasedEdge is a holding place for all of our information and processes, and all we have to do is grow and modify and tweak that process inside the software to accommodate the new level of volume that we reach every month. It’s all-encompassing, easy to use and mobile friendly, and it’s been an absolute game changer. It has built-in flexibility that can grow with you or be scaled back to accommodate your specific needs, whether your shop output is three kitchens per day or twenty kitchens per day. Furthermore, as for pricing, be it wholesale, retail, homeowner or commercial, is also broken down for ease of estimating.

“The other big benefit is getting everyone onboard. With EasedEdge there is no more printing out paperwork, sending out emails or communicating verbally to pass information to others in the company.

|

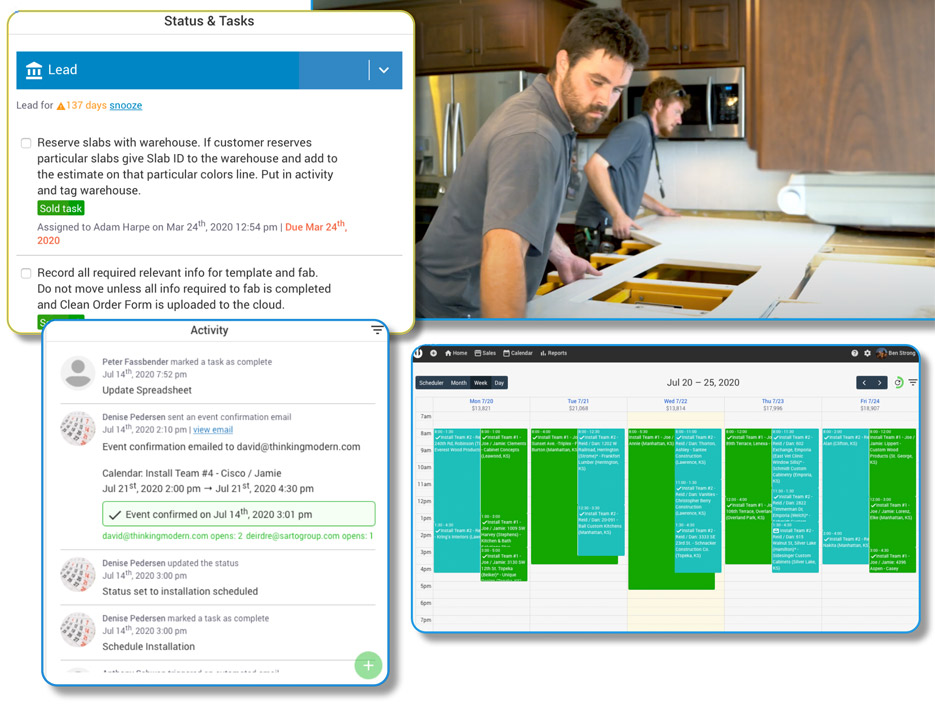

| EasedEdge offers absolute clarity on what days and times are open in coming weeks for an installation, no matter how many install teams a company has. You have the option of sending a confirmation email directly from the software to the customer. EasedEdge also notifies the person scheduling, so he or she can place the installation, big or small, with the correct installation team. |

If EasedEdge is used properly, the goal of it is that everyone has access to the information that they need, and only the information they need to do their job, and nothing more.

So you’re accomplishing all of your company’s functions on one digital platform. Whether it’s text, drawings to generate a quote or photo images, the process begins by tracking sales leads and what needs to be done with those leads, including what information has been passed on to the company.

“From there, it’s moved to the scheduling side. You’ve then got your calendar, your estimating, your invoicing and your payments all in one place, minimizing confusion and the payroll nightmare of double entries. Every action is recorded, and things like how many square feet used per week with dollar amounts, who is doing the most sales, or what jobs are having the most issues are all clearly visible. There’s also a place for digital templates that were uploaded from the customer’s house, and downloaded into the customer’s file. It’s at this point that programmers can have access to it, even before the template maker leaves the jobsite, and because EasedEdge is totally mobile-friendly and everyone is using the same platform, your fabricators now know what to cut next and what slabs to use. Once fabrication is complete, the installers then get the heads-up when the job is scheduled for installation. All the tasks for everyone in the company are broken out and at their fingertips, and when one job task is finished, EasedEdge creates the next task with the work flow totally visible to that job’s account manager. As a plus, during these processes, auto-emails are simultaneously telling your customers that their material is in, their job is being fabricated, it is ready for installation, or better yet, it’s installed.

“So to sum it up, everything the company does from start to finish is stored, and all the functions you want to create specific for your company’s needs are all doable.”

In closing, if unlimited mobile users, unlimited file storage, unlimited updates, and unlimited consultations sounds good to you,

visit www.EasedEdge.com to schedule a demo or to talk to a representative.

For examples of the quality fabrication Sarto Countertops is producing, visit www.sartocountertops.com.