Continuous Improvement

Ed Hill

Synchronous Solutions

Continuous means it never ends. It means forever. It means “there is no finish line.” Improvement means realizing an advance in performance. It means striving for excellence. It means that measurable Key Performance Indicators (KPI) are getting better.

To continually improve business performance should be the objective of every manager and every owner. Certainly, business leaders have daily duties to perform, but overall, their objective in life should be to meet established goals and achieve continuous improvement performance for the company. Forever.

The classic roles of business managers include:

- Planning. Establishing performance goals and preparing a written method to achieve them.

- Organizing. Forming a coordinated system of interdependent elements necessary to meet performance goals.

- Staffing. Hiring and training a group of employees with the necessary skills to complete the work of the company toward company goals.

- Directing. To guide through instruction, advice, regulation, and order toward achieving company goals.

- Controlling. To promote self-discipline and to assure accountability over the activities of the staff toward achieving company goals.

- Follow-up. Taking action to increase the effectiveness of a previous decision or assignment relative to company goals.

Those are the generic duties of a manager. Every job description should follow those guidelines. Notice how much they are focused on establishing and achieving company goals.

Goals Should be SMART

Use a simple process like this to set the standards for good company goals. They should be:

- Specific. Including a detailed description of what you want to accomplish.

- Measurable. Quantifiable so that you can track progress and so that you can know when you have achieved success.

- Attainable. Meaning that the specific objectives are realistic and possible to accomplish.

- Relevant. Meaning that goals are in alignment with the company's mission and vision.

- Time-bound. Meaning that there is a time limit for completion of each objective.

Goals must be clear, understood by all and published. Goals that are not written down and shared with everyone can become only a wish list. Ask any football coach about that and they will confirm that reality.

Having set goals, you should then have a clear description of “where you want to go.” At that point you need to know exactly where you currently are relative to each of those goals. You need to document the base line for your current status on each of the goals and the specific objectives within them.

If you are not satisfied with your current performance results, you must make systemic changes within your system. Your existing system is designed to give you the results you are currently getting.

If you want different results, you must make systemic changes in your business processes.

Lasting Improvement Requires Systemic Change

Systemic change is about how your business operates. Just “reading the riot act” to your employees may generate slight improvements, but that will not last. Lasting improvements require real changes to your system.

If you are not satisfied with your current performance results, you must make systemic changes within your system. Your existing system is designed to give you the results you are currently getting.

If you want different results, you must make systemic changes in your business processes.

Systemic change is about how your business operates. Just “reading the riot act” to your employees may generate slight improvements, but that will not last. Lasting improvements require real changes to your system.

If you always do what You’ve always done, then you’ll always get what you’ve always got.

Continuous improvement means being focused on the right priorities; it is not just working on the squeaky wheel. What to change must be based on data, not opinion. Every business system has a constraint and you will need to know where yours is or, more importantly, where you want it to be. A business, like the links of a chain, are only as strong as the weakest link. Working on a process that is not your systems constraint will not improve your system. Your process will always have a constraint (a weakest link) so it is better to know where yours is rather than chasing it around every day. That is the difference between proactive and reactive management.

Imagine a football game without a scorecard. The correct strategies and tactics require knowing the score every day.

Goal Tracking

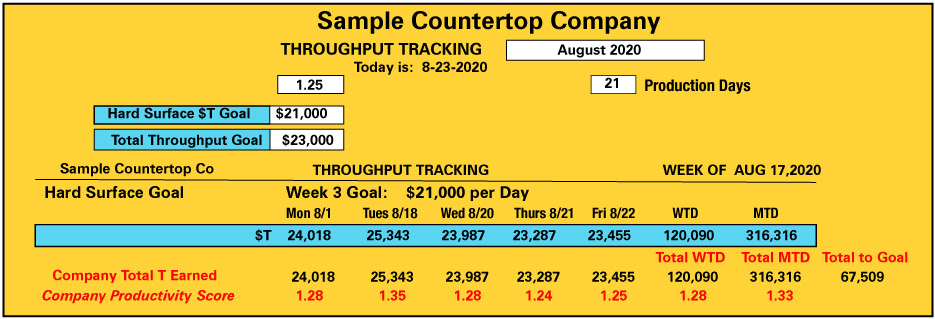

Goal tracking has to do with daily reporting of the performance status toward your goals. We advocate using a financial metric called Throughput ($T) which is the measure of value added. $T is the difference between the price your customers pay for the finished product and your investment in raw materials for that product. You can set a goal at the beginning of a month for an amount of $T to be earned, then track it every day to know the status to that goal. It’s recommendend to do a daily report showing that performance status.

The Company Productivity Score is the financial performance reduced to a single number, which can be shared with everyone in the company. For example, the Goal is a score of 1.25 and the month-to-date score is 1.33, so the company is $67,509 ahead of the goal as of this date. This report allows managers to take action every day if the company is falling behind the monthly goal. Waiting until the financial report for the month, which comes out a couple of weeks into the next month, is too late. Continuous Improvement requires knowing the status to goals every day.

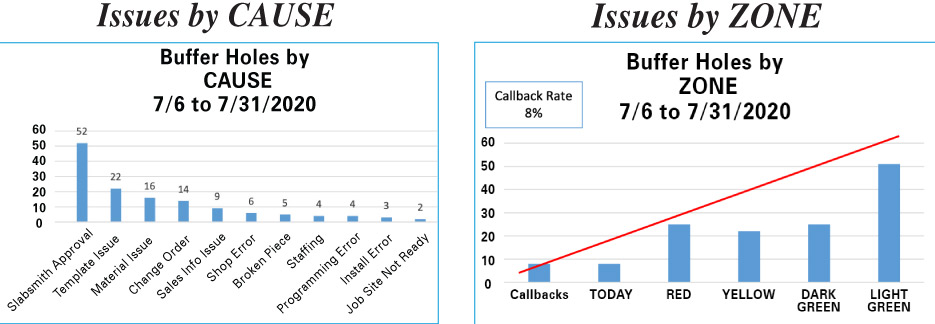

Issue Tracking

“Murphy lives.” The fact is, things go wrong in every business, particularly custom businesses like construction and remodeling. Some of the issues are frequent and even predictable and are called “common cause” variations. These issues can become chronic when allowed to persist. Tracking these issues allows the managers to focus on the most common and to initiate corrective actions to prevent them. More importantly, tracking the common cause issues throughout the pipeline allows a focus on priority of action. An issue identified early in the pipeline, while important, would not have the same priority as an issue near the end of the pipeline which would be a greater threat to the completion of the job and service to the customer.

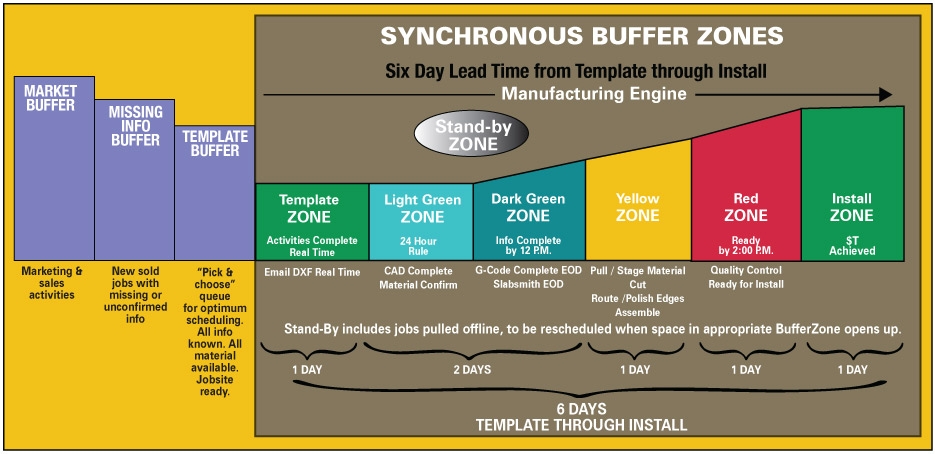

Issue tracking can be accomplished from sales through job completion by dividing the process into colored zones (called Buffers) covering the flow of materials and information from beginning to end. The Synchronous Buffer Zones diagram is an example of a Buffer Chart for a countertop manufacturer.

The Buffer Management Meeting

Purpose: to identify and record buffer problems and assign responsibility to fix them.

- Meetings are held at least once per day at a designated time and place, for a minimum of 15 minutes.

- Everyone should be on time and prepared

- The status of each zone is reported, relative to where every job should be in the pipeline

- Action items and the person responsible for each is communicated at each meeting

- Data is maintained to allow analysis of the most chronic issues affecting a smooth flow of jobs.

This is the essence of proactive management. During the month, this data can be plotted by cause and by zone. Using an automated report format, preparation of this information can be systematic and requiring no administrative burden at all.

This is the essence of proactive management. During the month, this data can be plotted by cause and by zone. Using an automated report format, preparation of this information can be systematic and requiring no administrative burden at all.

This is a way to respond to issues in a proactive (not reactive) manner and with priority of effort. This is a way to establish a robust continuous improvement program that will bring enormous dividends to your business.

In Summary: Plan, Schedule, Track and then ACT on the data.

Plan based on reasonable projections and set SMART goals. Schedule the necessary dollars every day to meet those goals. Track performance every day relative to the established goals. Collect data on shop and field operations to identify the chronic issues that are consuming the time of your people. Then act on the information you have collected to prevent the most chronic of the issues.

Keep doing it forever. Never become satisfied. There is no finish line.

For more information on establishing a robust Continuous Improvement program and how to be prepared for the coming resurgence of the economy, contact Ed Hill at Synchronous Solutions, www.synchronoussolutions , 704-560-1536 .