Stoney Creek Granite: Bedrock of America

How an American quarry became part of the fabric of our country

How an American quarry became part of the fabric of our country

– and continues to honor that legacy

Karin Kirk

usenaturalstone.com

|

|

The massive granite base for this iconic statue is Stoney Creek Granite. |

|

|

Block trimming at the Stoney Creek quarry. Historically and currently, the quarry can produce very large and dimensionally stable blocks of granite. |

Diagrams and photos © Karin Kirk.

Every block of stone holds a story. Not just in its geologic past, but also in the ways that stone becomes part of human history. In 1886 the Statue of Liberty presided over New York harbor to greet waves of immigrants earnest for their chance to pursue the American dream. Lady Liberty stands on a pedestal built from American granite, quarried 80 miles away, off of Long Island Sound. The stone is from Branford Connecticut, which was home to more than a dozen quarries and a workforce of skilled stonemasons and quarriers from around the world. Families from Italy, Sweden, Germany, England, Ireland, Scotland, and Finland settled in Connecticut to work in the dusty, noisy, and prosperous quarries. These immigrants built the very foundation of one of the defining symbols of America, which in turn, welcomed thousands of new immigrants to American shores.

Darrell Petit, who’s worked at the Stony Creek Quarry for over 30 years, admires how “the great immigration workforce” played a large role in launching the Stony Creek granite into prominence. Over 160 years later, Stony Creek’s legacy shines as brightly as ever, upholding tradition while keeping a clear eye on the future.

“We have a really patriotic story,” says Tom Cleveland, Director of Sustainability at Stony Creek Quarry. Behind every successful quarry is a collaboration between the forces of nature that created the stone, and human inventiveness that built it into a successful venture. What better time to celebrate American ingenuity and craftsmanship than right now.

A Granite Capable of ‘Monumental-Scale Work’

Although granite is a common stone in New England, the Stony Creek granite has an ability few can match. “If architects need huge blocks, this quarry can make them,” says Cleveland. Petit describes the quarry’s output as “colossally large scale blocks” that make “monumental-scale work.” Petit praises the stone as “capable of interacting with the world’s great designers.”

In addition to the Statue of Liberty pedestal, Stony Creek granite forms the Battle Monument of the United States Military Academy at West Point, New York, designed by Stanford White (McKim, Meade & White) made from a single, seamless piece of stone of astonishing scale: 46 feet tall and 5 feet in diameter and 96 tons. Dealing with stone that large is no mean feat in any era, much less in 1897.

Stony Creek’s combination of an impressive stone and the creative efforts of designers has produced scores of iconic works, particularly in the Northeastern U.S. The classic variegated pink, black, and white granite can be found on the campus of Columbia University, Battery Park, the Smithsonian, and the landmark Phillip Johnson designed former AT&T corporate headquarters, as well as sidewalks, parks, and facades throughout New York City, Boston, Philadelphia, and Washington D.C.

Petit appreciates the outsized role of Stony Creek granite: “We’re part of the legacy of classic American quarries that built the foundation of this country’s architecture.”

Early Adopters of Sustainability

“Sustainability is a cornerstone of our brand,” says Cleveland with equal parts pride and enthusiasm. “We want to exert leadership by promoting natural stone as the sustainable building material.” The stone industry’s standard for sustainability is called ANSI/NSC 373, which sets various benchmarks for ethical and environmental performance throughout a quarrying operation. The Stony Creek quarry obtained Gold-level sustainability certification in 2018.

Ariel Russ worked on Stony Creek’s original sustainability certification as part of her graduate degree in environmental management from Yale University School of Forestry, located just 20 minutes away from the quarry. “It was really cool to get boots on the ground – literally – and to see the whole operation,” she says. The first step toward managing one’s footprint is to understand where the big draws of energy and resources are occurring. So Russ compiled and analyzed baseline data on the amount of electricity, gasoline, diesel, water, and chemicals used in the operation.

Russ describes quarrying as “a very slow, natural process. It didn’t feel deleterious.” She came away with an affinity for the small and careful operation. “It doesn’t feel as industrial as I’d originally anticipated. It’s not super loud, it doesn’t feel aggressive,” she says.

Russ passed the baton to Cleveland, who now spearheads Stony Creek’s sustainability program. Cleveland is part of a new focus to quantify ‘embodied carbon,’ which is a tally of the amount of energy and greenhouse emissions used during the manufacturing of materials. Although buildings typically employ ways to save energy during the structure’s lifespan, the up-front energy that’s inherent in the materials is sometimes overlooked. Cleveland would like to change that, and he emphasized that since natural stone was created by the earth, naturally, the amount of energy required to make it is smaller than other materials. “We’re in a race to reduce carbon emissions,” says Cleveland. “The most important thing is just not putting it into the air.”

|

|

Above, left, from left: Darell Petit, Tom Kennedy, and Ariel Russ. Above, right: Tom Cleveland: sustainability watchdog for Stoney Creek operations. |

Cleveland went on to describe some of the company’s sustainability efforts, such as reducing the use of blasting in the quarry and instead using diamond wire saws to remove blocks from the quarry face. Compared to blasting, using a wire saw generates less dust, is less disruptive, and is safer for quarriers. Stony Creek has also managed to reduce their use of toxic chemicals, dramatically shrink their solid waste output, and has adopted a more deliberate planning process throughout their company so that the impacts on the surrounding landscape can be minimized. The sustainability standard requires public communication and transparency, so you can read about Stony Creek’s benchmarks in their corporate sustainability report.

Both Cleveland and Russ are excited about larger shifts in the industry, where customers and architects are helping to drive improvements in environmental stewardship. “A quarry is at the root of the supply chain,” says Russ, and what better place to start improving the environmental impact of a project.

|

|

Above: 303 Park West Avenue - Polished Stoney Creek granite base. |

|

|

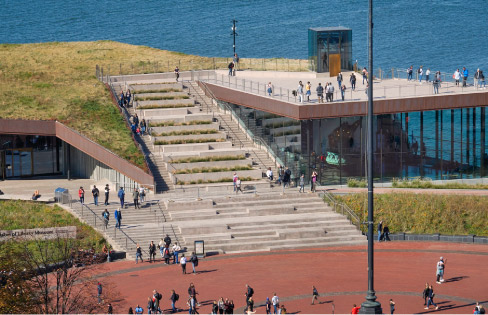

Above: The Statue of Liberty Museum, features new construction using Stoney Creek granite. |

|

|

Above: Smithsonian National Museum of the American Indian – New York City: Columns turned from Stoney Creek granite |

|

|

Above: Stoney Creek uses wire saws to economically separate blocks from the quarry face. Less dust, less waste, and it’s safer, too. |

Managing Stony Creek’s ‘Ongoing Legacy’

Petit speaks to a different type of sustainability – the ability of the quarry to continue to generate stone for historical projects. For these “ongoing legacies,” new stone has to match the original stone. When historic projects undergo expansions or renovations, the quarry can ensure that the correct stone is in continuous supply. For example, the floors of some buildings of the Metropolitan Museum of Art are made from Stony Creek Granite. As the museum expands, the same stone can be matched to existing stone.

The Statue of Liberty is another chapter in Stony Creek’s enduring story. More than 130 years after the original granite pedestal was built, about 450 tons of freshly quarried Stony Creek granite was installed throughout the brand new Statue of Liberty Museum, which opened in 2019.

These historic projects require more care and planning than when starting with a blank slate. Getting the details just right is a major focus for Petit and his colleagues. “It leverages our knowledge and experience,” he says.

Projects Great and Small

Not every project involves 25-ton blocks of stone or 100-year-old architecture. Stony Creek granite is used for more typical projects, too. “We’re open to the community,” says Petit. Homeowners, contractors, architects, landscapers are welcome to visit. “If you’re looking for stone, go to the source,” he advises. Stony Creek granite can be used as countertops, veneer, stair treads, building stone, and landscaping stone. In any case, Petit would be happy to lend advice on how to best use the stone.

“There’s no better phone call to make than to the origin, instead of 3rd-, 4th-, or 5th-hand information,” says Petit. “We’re an educational resource.”

Stewardship of the Stone

For a stone that’s made such a big impact, the quarry is surprisingly small. “It takes like 10 minutes to drive around the whole thing,” says Russ. “It’s very tangible.”

The 55-acre site is “completely surrounded by civilization,” says Petit. “We have to operate as environmental stewards.”

And while the massive blocks are the hallmark of the operation, every piece of stone that comes out of the quarry has a purpose. From 30-foot long blocks, down to crushed gravel, “everything on this property is a material that has its use,” says Petit.

Petit explains that sustainability can’t be an afterthought – it’s at the forefront of the business. “You’re after the choice blocks,” he says, which take time, experience, and care to extract. The ethos of a sculptor shines through in his comments. “There’s no need to proceed recklessly or carelessly,” he says. “We’re working with the utmost respect.”

A Tectonic Cataclysm

While a 160-year old quarry is noteworthy, the Stony Creek granite is far older than that, of course.

New England is the geologic equivalent of one of those disastrous traffic-accident videos one sees on YouTube, where at first one car smashes into bridge abutment, and then cars from behind skid into the scene, adding layer upon steaming layer to the carnage. On a continental scale, New England took shape as one landmass after another slid into the coastline, crumpling up the existing rock layers, wedging oncoming rocks into the midst of existing rocks, and re-melting old rocks into newer versions of themselves.

At the end of a 200 million-year sequence of tectonic cataclysm, all the world’s continents stood fused as one colossal landmass: Pangea. During this moment in Earth’s history, the Stony Creek Granite was beginning to cool off for at least the second time.

The deep history of the Stony Creek granite is told by some of its tiniest ingredients. Minerals called zircons are geology’s storykeepers. These minerals crystallize from liquid magma, and have a remarkable way of preserving the telltale clues of subsequent events that have taken place, packing a huge expanse of space and time down into a tiny grain.

“Go to Figure 5,” says Robert Wintsch, as he guided me through his research paper. Wintsch is a geologist who has spent years solving the puzzle of the Stony Creek granite and similar rocks that dot southern New England. In the paper, Figure 5 showed magnified images of zircon crystals that are about the size of a small gain of sugar. Detail by intricate detail, Wintsch narrated his way through the image, pointing out the original core of the crystal that first cooled around 360 million years ago in the Devonian Period, around the same time as the first four-legged animals nosed out of the sea and began to explore the land.

But the story doesn’t end there. The texture of the zircon crystals revealed a spider’s web of cracks running through them. In some cases the crystals had become “dismembered,” says Wintsch, as the stone was fractured. This microscopic evidence spoke to a landscape-scale event, as the Stony Creek Granite got caught at the “tip of the spear” of an oncoming landmass called Avalon. The collision shattered the rock and shoved Stony Creek granite deep into Earth’s crust, where it melted somewhat, but not completely. As the rock cooled off, large, blocky feldspar crystals formed. The zircon crystals, which survived the re-melting event, received a fresh layer of material around their edges, not unlike a tree ring. At this point in geologic time, 288 million years ago, the supercontinent of Pangea had finally taken shape. A Himalayan-scale mountain range loomed over New England. This was the last tectonic collision endured by the eastern U.S.

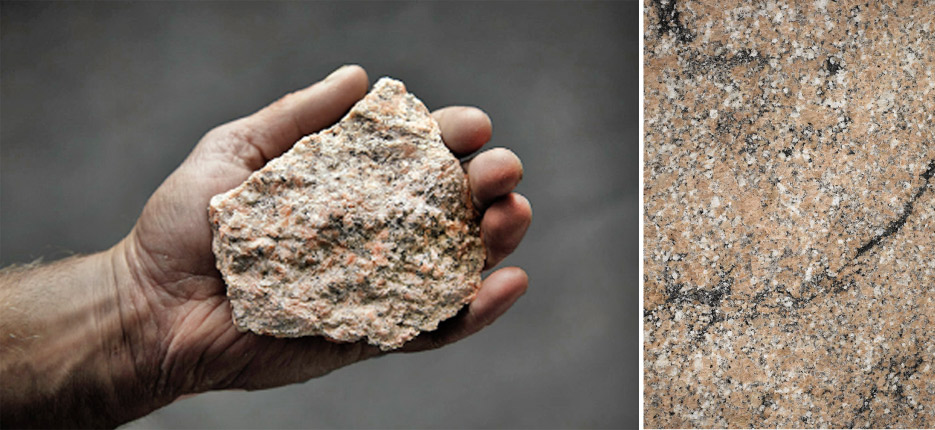

|

|

Polished or rough – Stoney Creek granite's texture and mineral composition reveals its fiery geologic formation. |

Geology Holds the Key to Stony Creek’s Large Blocks

Wintsch speaks with a sense of affection as he describes the Stony Creek granite. “Like cirrus clouds,” he says, of the wispy bands of black mica that give the stone a hint of a wavy, linear grain to it. The subtle movement is leftover from the stone’s original texture, and it gives the stone character. But when the stone was partially re-melted it erased most of the stone’s linear flow and replaced it with a blockier texture, which has no particular direction to the grain. This lack of grain is what allows the Stony Creek to be quarried in large blocks, free from planes of weakness. Stony Creek’s re-melting turned out to be its 288-million-year-old secret to success.

While Wintsch looks for clues buried deep in the past, Petit asserts that even in the relatively short span of human history, Stony Creek granite has made a lasting contribution. When it comes to sustainability and long-term use, “there is no better material than stone,” he says. “Our legacy is in terms of centuries.”

Karin Kirk is a geologist and science educator with over 20 years of experience and brings a different perspective to the stone industry. Karin is a regular contributor to usenaturalstone.com and the Slippery Rock Gazette.

This article is the first in a series Karin Kirk is writing about American quarries. If you work for a quarry that’s a member of the Natural Stone Institute and you’d like your quarry to be featured here, contact Karin Kirk, karinkirk at gmail.com.