Stone Studio: This Second-Generation Business is an Example of Careful Planning and Community Service

Peter J. Marcucci

Photos Courtesy Stone Studio

|

|

Sample as well as workspace: Dustin Hughes’ Stone Studio office features a Golden Crystal waterfall desk and a Titanium granite wall feature. |

In 1980 Dexter Hughes opened the doors to his custom cabinetry shop in Nash, Texas. Dexter’s son, Dustin, was also born around this same time.

As the years progressed, young Dustin would spend his time off from school learning how to finish cabinets, he recalled. “From the time I was six, my dad would take me to work with him. Back then, our cabinet shop was down the hill from our house, and I would get off the school bus and go to work sanding and finishing. I liked to work with my hands and liked streamlining the process to make it more efficient. I’m still passionate about this.”

Continuing to work side-by-side with his dad, Dustin’s love and passion for quality craftsmanship continued to grow in lock-step with the company’s products and clientele.

Digital Technology Brings Opportunity & Challenges

By his early teens, Dustin’s love and passion had increased to include a vision of automation for the family business. Dustin was developing into a born leader, and by age eighteen had become an important part of Contemporary Concepts (CCI). During this time, the company’s cabinets were sold to the residential market. In 2001, CCI additionally became a commercial supplier. With Dustin at the controls of their first CNC, the extra volume needed could be produced, as well as allow the company to expand its product line, he explained.

“I wanted to grow the company, and in 2003 I bought my dad out. At the time, we were bidding on the stone tops that were sold with our cabinets, even though we were outsourcing them. This got to be a nightmare just from the coordination factor, but in 2015, we got a large project at the Walmart corporate headquarters, and I decided that this was the time to take the plunge and get into the stone business.”

Dustin took the plunge in 2016, and bought a Park Industries Yukon bridge saw. in 2018, the stone division was officially christened Stone Studio. He and his team of craftsmen offered a full line of first-quality materials and products into the residential and commercial market, and didn’t look back. The company quickly outgrew its current space in Texarkana, Texas, and a new, more efficient space was needed, he continued.

“We had looked at a building to buy in downtown Texarkana, Arkansas. It was where an old Coors beer distributor had been. It had everything we were looking for, including a 6,000-square-foot showroom space, and an 8,000-square-foot shop space. Luckily, we had a great team of guys, but none of them had any experience with digital equipment.

“It was pro hockey player Wayne Gretzky who once said, ‘You miss 100 percent of the shots you didn’t take,’ so we took our shot at going fully digital, and bought a Park Industries Saberjet XP 5-axis CNC, and a Park Industries Fastback 2 Edge Polishing Machine. We also went from hard templates to digital templating and a Slabsmith. This process was like going from a horse and buggy to a jet. It was a little painful in the beginning, but our people were very motivated to learn it, and they liked getting away from the manual labor.”

A Sasso K-Lux single head surface polisher was next on the list to be purchased, but due to the COVID-19 crisis in full bloom at the time of this interview, the K-Lux has been put on hold indefinitely.

|

|

“Our fabrication shop is outfitted with a Park Saberjet, a combination saw that cuts with a diamond blade and a water jet. We also have a Fastback II line polisher which can polish all our flat edges at 50 inches per minute. We handle all our material with two Weha A1500 vacuum lifters. All of our inventory is digitally logged in our Slabsmith software, allowing the customers to view our inventory online, also allowing us to do precision grain matching.” – Victor Swithenbank |

|

Call to Duty

Speaking of COVID-19, Stone Studio has currently taken on the fabrication of something with a different twist, continued Dustin. “A while back, the Governor of Texas contacted all of the in-state manufacturers, and asked them to look at their operation to see if there was anything they could do to help with making medical supplies. I had thought about the fabric side and making masks, but that wasn’t for us and we couldn’t help. But I’m in an association, and one of my peers posted a picture of an intubation hood. It’s a Plexiglas box that goes over the patient’s head, so that when they cough, it keeps the cough vapor contained. It has holes in it, so that the doctor’s arms can reach through to do an exam or to install a ventilator. Anyway, a friend of mine is an ER doctor at a local hospital, and I asked him about making these hoods and he said, ‘Yeah, man! That would be great!’

“I then asked our people one Saturday morning what they thought of the idea. We got the specs, had some Plexiglas delivered from a local glass shop, switched gears and put the intubation hoods into production. By the end of the day that Monday we had built four, and sent them to a local hospital. Soon after, they called us back and wanted another four. The first person they tried it on tested positive for COVID-19, and it made us feel good knowing that we had helped a little bit. After that, we posted it on social media and the news caught wind of it, and then a lot of people called us asking us for one.”

|

|

Above, left: Stone Studio fabricator Justin Moore finishes an aerosol protection box to be used by health care providers when intubating COVID-19 patients. |

People, Safety and Logistics

Not including Dustin, Stone Studio’s production staff consists of three shop craftsmen, four installers, one programmer, two sales people and an office manager. This small but efficient team produces an average of one kitchen per day. According to Dustin, time-consuming edges such as large mitered or waterfall are quite popular in their service area at the moment.

“Our people are very involved and detail-oriented, and passionate about our stone fabrication business. They love it even more than me, and I really appreciate that. I’ve shown them trust, and it’s been reciprocal. I also think it’s really helpful to ask our people what they think we need, and what we can do for them. It also shows that you trust them to help you make decisions, instead of just making them on your own. They take great care of our customers. It’s almost scary how rarely I hear about a problem, because they don’t want me to hear about it. And, heck, it makes me feel good that they solve it!”

For safety’s sake, Dustin has a voluntary OSHA consultation every year, he continued. “At first, I was very nervous about doing it, but it’s been a great relationship, and hugely beneficial. There were some things that we didn’t know and seemed trivial to us, but it was important to OSHA, and it provides us with a layer of confidence, because if we do have an accident, we know that we did our best to prevent it from happening. Our insurance company likes this, as well.”

An approximate sales ratio of materials for the company’s 50/50 mix of residential and commercial clients is 25 percent granite and 30 percent quartz, with the remaining being a mix of quartzite and marble. Custom products consisting of countertops, showers, furniture and fireplaces are the norm.

Many of Stone Studio’s clients are obtained through word of mouth, said Dustin, however, he is not one to sit and wait when it comes to acquiring new work, he explained. “For residential, we invest heavily in Facebook, Instagram, Houzz and Google. On the commercial side, we network with all the local contractors, where one thing leads to another, especially with their estimators. We will work with a company in one location, and when they move to another, they bring us with them. We’ve worked as far as Miami, Florida, San Francisco, California and Denver, Colorado. As for our residential side, we will travel as far as one hundred miles from Texarkana.

“We want to sell an experience when people buy here, and not just make a sale that’s based on price. We offer seven-day turnaround if their material is in stock, and if they are ready for us to install. We also survey our residential clients after the installation, to know if we are doing our job.”

As for Stone Studio’s showroom, it features large format samples displayed like art throughout the 6,000 square foot space, said Dustin, adding, “I went to Brazil in 2017, when we had opened our showroom. Everything we stocked it with at that time was bought from Brazil. Lately, though, much of the granite, marble and quartz we buy is from a local company called the Triton Stone Group. However, we do import the higher-end quartzites from Brazil.”

|

|

Above: Bar and engraved panel with the word “Formation,” for the Dallas Cowboys Football Club, at the Star in Frisco, Texas. Below: This 3/4 slab mitered quartzite top showcases Stone Studio’s mastery of fabrication skills. |

|

|

|

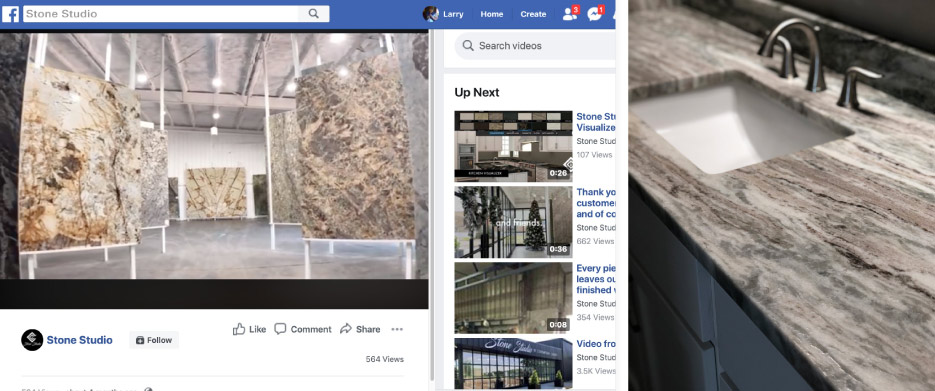

Above, left: Video from the Stone Studio Facebook page with a tour of the Brazilian slab layout in their showroom. These beautiful slabs are the stars and focal point of this part of the showroom. Above, right: Granite vanity top, leathered finish to accentuate the grain. |

Dustin’s Take on Porcelain

“Victor, our shop manager who also does the programming, has given me a lot of perspective on large format porcelain, so whenever I talk to distributors and ask what percentage their customers are doing with porcelain compared to three years ago, they tell me that it’s growing in popularity. We are actually looking at our first porcelain job now, because we are putting together a tile package on a commercial project, and in their bathrooms, they want porcelain slabs. We are also going to do our bathroom here with it, just to get our feet wet. We’ve talked to a couple of guys out west that do really well with porcelain, and we are either going to send our guys out there to train on it, or have them come here. Porcelain has a lot of drawbacks, but if the customer wants it, I want to give them what they want, especially when no one else in this area wants to. It’s a good opportunity.”

“What has helped us make this company a success is our determination and innovation. It’s also from going to trade shows and seeing what’s new or what’s changing, and talking to industry people three or four times a year to learn from each other. It’s also being an open book, and asking for help when there’s something we don’t know.

“As for the future, we have a vision. We want to expand our operation, and put showrooms like we have here in different parts of the country as far away as five hours drive time. Additionally, we will continue to stay on the edge of the latest and greatest technology with the most value. We are not afraid to take on a challenge.

“There’s a famous quote that goes, ‘In business, always stay uncomfortable.’ Well, I’ve been uncomfortable a lot lately. But it’s a good uncomfortable.”

Stone Studio is a member of the Stone Fabricators Alliance and the Texarkana Chamber of Commerce, and regularly volunteers for local charities.

For more information visit www.ccimill.com and visit them on facebook.com/ccimill .