How Lean is Your Shop?

Advice on Optimizing Your Shop from CNC Expert Peter Hauser

Times are tough, but our industry is tougher. The Coronavirus pandemic is temporary, but the businesses we have all built up for decades are lasting. We are all running lean, and that is not necessarily a bad thing.

During the Coronavirus event– or during any business slowdown–is a good time to evaluate your shop and processes, and look for ways to streamline operations to be ready, leaner and better when business is back to normal.

So what are some things you can do improve efficiencies or eliminate waste and disorder? According to Braxton-Bragg’s new CNC Director, Peter Hauser, who is implementing the company’s new shop optimization program suggests the following:

|

|

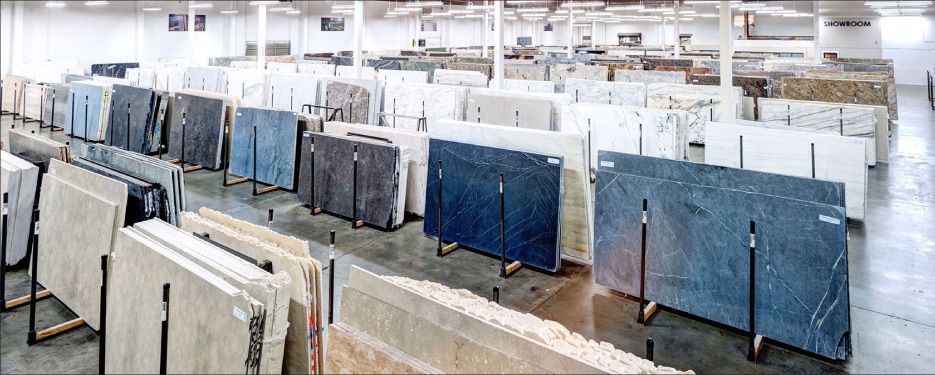

Use down time or slack time to photograph and organize your material and create your own virtual showroom. |

Safety First

Always take safety into account in all you do. From the way you move and store your slabs to the way you clean your facility, safety is top priority. Evaluate your shop and its ability to run safely. Can you move stone more efficiently? There are tons of material handling tools on the market, and enhanced protective gear and products to organize and make your job simpler and safer.

Sort It Out

Take inventory with a fresh set of eyes and remove all non-essential items and materials. This includes scanning all desks, fabrication stations, machines, mezzanines, and the addition. Store non-critical items for a few weeks and if the items have not utilized in that time, remove or discard.

Display It

Slabs are one of the most expensive investments in a shop, but many times they are unorganized and displayed like they are not important. Take this time to photograph and organize your material and create your virtual showroom for customer viewing.

Automate

Are you doing some tasks manually that you can automate or use machinery to complete them in a more efficient manner? Identify activities consuming your high labor hours and try find alternative options. Polishing all your flat edges by hand? Why not put the tops through a horizontal/vertical inline machine 1st or utilize your CNC more if the capacity is available.

Straighten It

Your team should determine the proper spot for everything in your facility, down to carts and A-frames. Determine the proper flow of materials in order to ensure the most efficient spot. Map each station with the location for each tool, cart, supply, etc. to create a complete facility layout.

Shine On

Clean everything top to bottom, because a clean work environment is a safe and healthy work environment. This step improves team morale and productivity. Keep it clean daily, so it doesn’t get overwhelming.

“You can think of your shop as a junk drawer. The more you have stuffed in there, the more difficult it is to find things you need, and not drop things. If you clean the drawer out to your key essential equipment and streamline your processes, things run smoothly and you get the result you want for your customers, employees and your bottom line,” said Hauser.

Maintenance

A slowdown is great time to review and implement an equipment maintenance program. Whether hand tools or CNC routers, everything runs better and longer when properly maintained. For example: carts might need new wheels, work tables or saw beds might need resurfacing – any tool or piece of equipment requiring maintenance is fair game for some TLC.

Standardized Procedures

Are all policies and procedures up to date? From unloading stone, through all stages of fabrication, to loading a completed top onto the install truck, there should be a standard operating procedure to ensure everyone is on the same page and operating at the highest efficiencies.

Slowdowns in business are scary and stressful. They can also provide opportunities for owners and managers to work on the business rather than in the business, allowing you to come out a better, stronger, and ultimately a more profitable company.

For more information on a shop optimization program, contact Peter Hauser, p.hauser@braxtonbragg.com or call 815-275-0366.