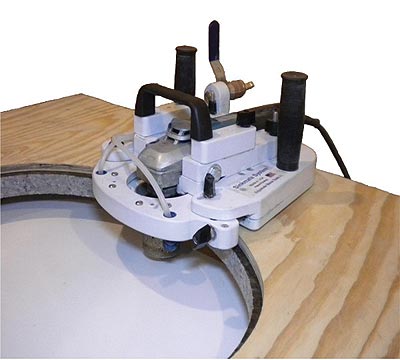

Sinkmate System Offered by Braxton-Bragg Delivers Fast and Clean Sink Cutouts

Braxton-Bragg is offering a faster and safer way to cut out sinks at an economical price. The Sinkmate System also gives small shops a way to compete with larger competitors, Product Manager Steve Bussell said

“The primary design is for cutting out sinks accurately and quickly and safely,” he said. “It follows an inexpensive template that can be made from plywood. There are guards that are provided so it’s very safe. You can do the work of accurately cutting out sinks in record time and safely, unlike the current tools used by most shops.”

The Sinkmate System uses three separate tools for sink cutouts. These three tools follow the same template, creating a very fast and accurate system for cutting, Bussell said. “The Sinkmate is specifically designed for just cutting out sinks. It’s a very safe process, and it uses water so it doesn't create dust.”

Sinks can be cut out at an impressive rate, Bussell said. “If you want to cut an accurate vanity sink out in four minutes, it will let you do that.”

The three components of the Sinkmate System are:

The Chopper TS6 uses a 6-inch contour blade. It can cut a 3 cm lavatory bowl hole in less than four minutes. Adjustable guides allow the operator to change the size of the sink hole. The operator can quickly change blade depth for step cutting while holding the blade at the perfect angle. Chopper saves clean-up time by leaving a vertical edge on the finish side of the bowl hole. It can also step cut the corners of a rectangular sink hole, leaving very little material to remove with a clean-up drum.

The Chopper TS6 uses a 6-inch contour blade. It can cut a 3 cm lavatory bowl hole in less than four minutes. Adjustable guides allow the operator to change the size of the sink hole. The operator can quickly change blade depth for step cutting while holding the blade at the perfect angle. Chopper saves clean-up time by leaving a vertical edge on the finish side of the bowl hole. It can also step cut the corners of a rectangular sink hole, leaving very little material to remove with a clean-up drum.

- The Tracker TS8 uses a standard 8-inch turbo blade and follows a template for straight and curved cuts. Tracker was designed to step cut while following the straight inside edges of a sink template.

A heavy duty pivot gives the operator a very accurate plunge cut and a trigger to quickly release the spring to lift the blade out of the stone. This allows the saw to be quickly repositioned for the next cut. Tracker has two flange wheels that follow the edge of the template. These wheels are adjustable so the operator can change the distance between the blade and the template. Tracker’s patent pending design allows the operator to step cut a curved countertop. Using all three tools together, an operator can even fabricate an outside radiused vanity.

- The Bandit RB2 is a variable speed router designed to clean up and polish the sink hole following the same template. The base of the tool has a rotating collar, which can be adjusted to change the distance between the abrasive and the template. This design allows the fabricator to make a smaller sink cutout using the same template and to also adjust for the wear on the abrasive.

For additional information on these products, contact the sales reps at Braxton-Bragg. Call toll free, 1-800-575-4401. Braxton-Bragg offers a full range of fabrication tooling and installation accessories including sinks, installation hardware, and every tool and piece of equipment needed to run a professional stone, tile, and polished concrete shop.

For more information about Braxton-Bragg and its publications and products, contact them toll-free at 800-575-4401 or visit the website www.braxton-bragg.com for current sales and new products.

![]()