Are You a Manufacturer?

Ed Hill

Synchronous Solutions

In his book Wealth of Nations, first published in 1776, Adam Smith wrote that there are only three ways to create wealth: mining, farming and manufacturing. All other methods of work, certainly including service industries, only redistribute the wealth. A quick examination of these three ways to create wealth reveals that although our nation is rich in natural resources, there is certainly a finite supply, and mining does not provide many jobs in today’s economy.

In his book Wealth of Nations, first published in 1776, Adam Smith wrote that there are only three ways to create wealth: mining, farming and manufacturing. All other methods of work, certainly including service industries, only redistribute the wealth. A quick examination of these three ways to create wealth reveals that although our nation is rich in natural resources, there is certainly a finite supply, and mining does not provide many jobs in today’s economy.

The USA has taught the world to farm and remains the most productive farming nation on earth, but as a result of mechanization, this industry no longer provides the millions of jobs that it once did. Manufacturing, throughout our nation’s history, has been the foundation of our economy. Making things (aka manufacturing) still provides many jobs, and again is a growing sector of our economy.

The technical definition of a manufacturer is “an organization that coordinates the efforts of skilled workers who operate various forms of tools and equipment to cut, mold, join and finish the raw materials into products that customers will buy.”

In order to be successful, there are three things manufacturers must do or requirements they must meet:

Quality. Generally, the quality of the finished product must be excellent. This is not a competitive opportunity. In other words, it is no longer valid to say that your quality is better than your competition. Everyone’s quality must be excellent, or you will not be allowed to exist in the market.

Pricing. The pricing of your products must be reasonable, but in a custom manufacturing market it is not much of a competitive opportunity, either. If you compete on pricing, you will become a commodity. Someone can always make it a bit cheaper. It is much better to maintain a reputation for excellent quality at reasonable pricing than to compete on pricing alone.

Moreover, in many cases, the price of your product is dictated by your customers, so you have little opportunity to negotiate.

Service. Time, speed, velocity. This is the competitive opportunity for the custom manufacturer. Most companies can produce a good quality product at a reasonable price. The best companies are those that can do all that plus do so faster and with more reliability than their competitors. It is one thing to quote fast lead times. It is yet another to be reliable to meet those quotes. Speed to market, while maintaining excellent quality and reasonable pricing, should be the focus of the successful manufacturer today.

Velocity Metrics

There are three primary metrics that measure time in a manufacturing system. All of them relate to the amount of inventory within the system. In other words, the more open orders in your system, the longer your time to satisfaction of any order. Inventory equals time.

Lead Time is defined as the time between the initiation and the completion of a production order. Basically, Lead Time is the days or weeks between the confirmation of a sale to the completion of that order at the satisfaction of the customer. Of course, that includes any quality corrections that must be addressed after the product was completed and installed for the customer. (See “The Curse of Callbacks” in the January 2019 edition of the Slippery Rock Gazette).

Process Time is the period during which raw materials are transformed into a finished product by a manufacturing procedure. Basically, this is the time from order entry into the manufacturing system to the completion of that order at the satisfaction of the customer.

Touch Time. This is the amount of time that a product is actually being processed at a machine and/or by an employee. For a man’s dress shirt, as an example, touch time is about ten minutes. For a granite countertop it is about two hours. Touch time does not include all the idle inventory time in which job materials wait between manufacturing operations. It also does not include the time a file waits on the desk of some Project Manager prior to release into manufacturing. In ultimate Lean Manufacturing, called “single piece flow,” the process time approaches the touch time.

In custom manufacturing it is reasonable to maintain some accommodation for “Murphy” (aka: stuff happens). In making widgets, like automotive parts or printing, engineers work to eliminate variability. In custom manufacturing, we accept the inevitability of some variation (Murphy) and we set the system to deal with it. The two things you can and should do to accommodate Murphy are maintaining some Protective Capacity and some levels of inventory “Buffers” between operational steps. Both of these strategies are essential in the custom manufacturing world.

The Process Time is the velocity you can control within your system. It begins when you have confidence of three essential elements for any manufacturer:

1. All information known. All means all. You can’t possibly produce a finished product without knowledge of exactly what the customer wants. It is foolish to enter a job into your system when any piece of information is unknown. This is one of the most important disciplines of the successful manufacturer. It is the responsibility of the Sales and/or Project Management staff to secure this information before a job is released to manufacturing.

2. All material available. Again, all means all. Either the material should be on site or there should be some confidence that the necessary quantity will arrive before the first manufacturing step. Any delay in a manufacturing step will lengthen the Process Time.

3. Jobsite ready. This means that someone (probably Project Management) has spoken with the customer to confirm that all preparatory steps will have been completed before the arrival of your Team for Templating and Installation. This would include items such as cabinet installation, other trades out of the way, easy access to the jobsite, etc.

Ultimately, Inventory equals time. In any manufacturing system, the amount of orders within your system determines your lead and process times. If you have three weeks of orders from Sales through manufacturing, you will have a three-week lead time. If you have two weeks of orders between Templating and Installation, you have a two-week process time.

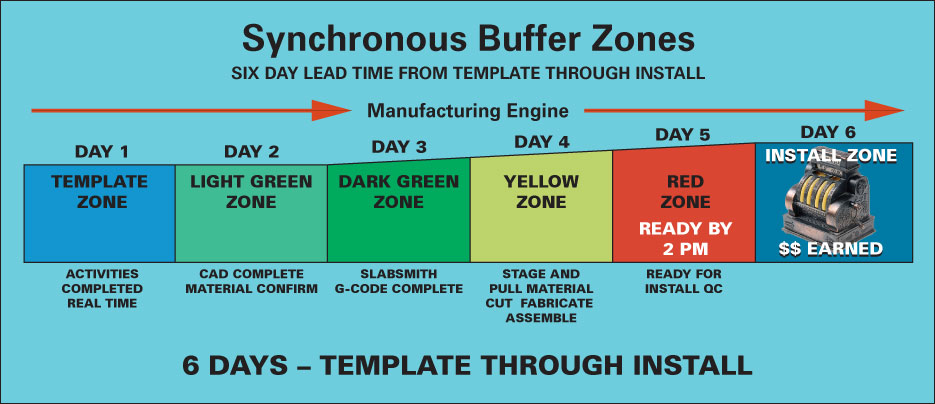

The market, which feeds the “Manufacturing Engine” depicted in the graphic below, is fickle. Completely. The smart manufacturer is one who carefully manages the release of new jobs into the Manufacturing Engine. The fact is that controlling the quantity of orders within the system can increase its productivity. Conversely, allowing the market’s fickle nature to determine the quantity of work-in-process will decrease system productivity.

Imagine a mountain river. Where the water is deep, it is moving slowly. Where the water is shallow, it is moving rapidly. The velocity of orders moving through your system is much the same. Maintain the number of days inventory you desire as a process time. Release new jobs into the system at the same rate that completed jobs exit the system. That is how you maintain a fixed process time.

Manufacturing is an admirable vocation and can provide a sense of accomplishment with every completed job and satisfied customer. Beyond excellent quality and reasonable pricing, it’s all about speed and reliability. If you haven’t already, read The Goal by Dr. Eli Goldratt. This book explains the value of rapid process times and how to synchronize your business system.

For more information on how to maintain a rapid and reliable process time, contact Ed Hill at Synchronous Solutions, www.SynchronousSolutions.com , or call 704-560-1536.