Safety First

Codiak San Herrell

Solid Surface Designs

It had been a normal day in the shop, so far. I was walking back to my work area after lunch, headed toward my helpers when someone ran up to tell me that one of them had de-gloved their finger between two slabs, narrowly missing getting it crushed, but still peeling some skin off. He had held onto a slab a little too long after the clamp was released.

On the weeks prior to this event, I had prided myself on keeping a decent track record of low recordable accidents under my watch. But instead of getting down on myself, I knew our team needed to learn and grow from this narrow escape.

In after-event analysis, the forklift driver and the slab guider may have been too comfortable with their jobs, underestimating the magnitude of an possible accident. And obviously, the guider’s hand shouldn’t have still been on the slab. Should we have Instituted the procedure of the guider announcing “clear” after picking or releasing the clamp? We learned a few important things from this incident: never forget that slabs weigh thousands of pounds. You can never be too careful even doing routine tasks moving a slab. Always follow safety procedures and protocols, check your fall zone, and call ”Clear” when releasing a load.

Solid Surface Designs uses the Southwest Missouri Safety Company to help keep up to date with OSHA’s rules and regulations. We have an in-house safety/maintenance man, Brad Stanley. We hold a safety meeting once a week to help keep us safety minded. It is a time to bring concerns and ideas to a group, to focus on handling terror-like incidents or natural disaster protocol.

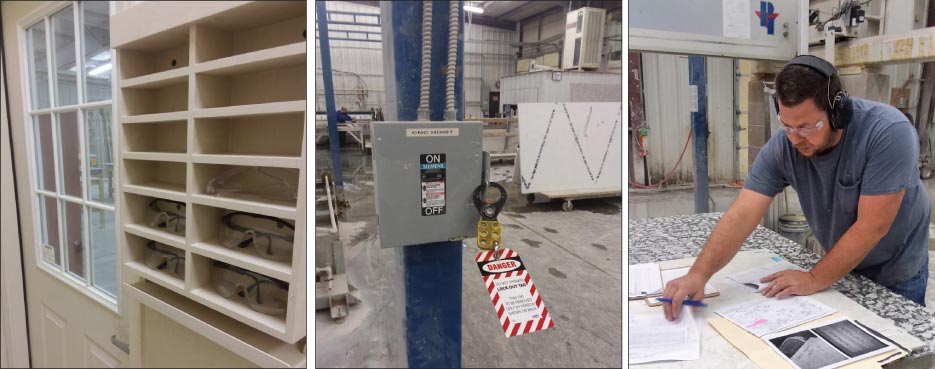

To help with implementing steel toes company wide, we are having a “boot truck” make visits to sell employees nice boots. This plan uses a payroll deduction payment method, worked out with our company. We are also advocate of the common “lock out tag out.” As well as seat belts and safety glasses. Safety glasses being many managers or safety committee’s main headache. We found that after being diligent and reminding employees continuously does pay off and workers will start humoring you.

|

|

Above, Left: Two ideas to promote safety in the shop: A handy storage space and easy access for eye protection for visitors

|

As for customers and visitors, we have safety glasses stationed next to the door coming from front office to shop, also from the showroom to shop. The customer safety glasses are also a different style of glasses than employees wear to prevent over circulation. We are constantly doing air sample testing to monitor silica levels to prevent serious illness.

Let’s face it, safety is always going to be a major topic in any business. Easily preventable injuries that are not prevented can put a dent into a company’s bottom line. A team can institute a book full of rules and policies, but without constant awareness and enforcement, your record for non-recordable accidents will never reach as many days (without an incident) as you want it to. And even if you achieve a good safety record, you cannot let yourself become complacent about the importance of constant personal safety vigilance for yourself and your peers, or dismiss the risk of working with and moving heavy materials.

Codiak San Herrell is a native of Aurora, Missouri. He is Warehouse Supervisor with Solid Surface Designs, where he serves on their safety and LEAN committee. Codiak is CPR / AED certified and currently working on other certifications.