The Curse of Callbacks

Ed Hill

Synchronous Solutions

A Callback is defined as an unplanned return trip to the jobsite, for any reason, to complete an installation. It does not matter who is at fault (the installer, the shop, the customer or anther trade). The effect is the same:

- The Customer is disappointed (at best) or outright angry (at worst). Word is spread to their friends and family that the fabricator did a bad job. Lost goodwill is very difficult to regain.

- The valuable time of the install team, or a service person must be utilized to complete the repair on a return trip.

- The established install schedule can be disrupted due to the need for return trips to jobs that should have been already finished.

- Your entire operations team must deal with the resolutions, which adds to the daily chaos.

- The financial cost of the return trip for the fabricator is very significant. It is much more than the labor cost of the Installers and the gasoline used by the truck. It includes the “opportunity cost” of the Throughput ($T) that could have been earned if that install team could focus on a new job.

Multiple return trips to complete a repair actually compound every one of these issues.

Multiple return trips to complete a repair actually compound every one of these issues.

What to Do, What to Do?

First of all, you should know your Callback Rate. This is the percentage of all installation jobs requiring an unplanned return trip. Simply keep track of the total number of jobs scheduled and the total number of return trips. Divide the number of return trips by the number of jobs and you have the Callback Rate. A realistic goal, although admittedly a tight one, is five percent, meaning five jobs out of 100 require an unplanned return trip.

However, I have found that it is more common that companies don’t know what their Callback Rate is, and when we do calculate it, the actual performance is more like 25 percent or more. I actually have seen Callback Rates exceeding 50 percent of all jobs. This is an unsustainable level of performance. Customers will disappear as your competition finds a way to do much better than this.

Knowing the Core Causes is the First Key

Measuring the Callback Rate is a start, but only that. More importantly, you will need to know the true core causes of these issues. What is the original domino to fall that caused all the others to fall?

This takes a bit of investigation as the true core cause is often not the same as your first impression. Drill down; investigate; ask questions.

The Callback was required because one top did not fit. Why was that?

- Was the template correct?

- Is the equipment properly calibrated?

- Is the template tech properly trained?

- Did the cabinets change after template?

- Did the cut parts fit the template?

- Could the slab have shifted on the router?

- Did you properly check the quality and dimensions of the piece before it left the shop?

It does take a bit of effort to drill down to the true core cause, but there is no way to stop the reoccurrence of these problems unless you know the causes and you take definitive actions to prevent them.

The Law of Unintended Consequences

By the way, some of the common steps that fabricators take to address Callbacks may not help at all.

An assigned Service Person can become a crutch for the Install Teams. “Why do I need to spend more time on this job? Joe can fix it.”

“I get paid regardless if I finish this job or not.” Trip charges to a customer who provided incorrect information are never enough to offset the actual loss of income. And, they can become a “nickel and dime” annoyance to the Customer.

Know the True Costs of Callbacks

What are the true financial costs of Callbacks? As said, it is much more than wage rates, supplies and fuel costs of the install team that does the repair. In fact, it is the opportunity cost of the lost income that could have been earned if that team had been able to install another job instead of taking drive time and job time to do that repair.

Throughput ($T) is the measure of value added by the company. It is the monetary value of all that the Fabricator does. It is the difference between your investment in materials and the amount you are paid for the finished product.

A $T Example:

A kitchen countertop job with a sales value of $5,000 might have a material cost of $2,000. The $T for that job is $3,000. Through the work of your company and its people, you made that $2,000 investment worth $5,000 to your Customer.

You created $3,000 in value. That is $T.

Effectively, $T is only earned when an installation is complete and the Customer is satisfied. Customers don’t pay for templating, cutting, routing or polishing. They only play for the finished product. Therefore, Installation is “where your cash register rings.” As such, it should be your point of focus. Everything you do should enhance your ability to complete installations on time and with excellent quality. A Callback is the worst thing that can happen to your ability to earn $T. Not only did you not earn the $T as planned, but you now must commit more of that valuable resource to get the job completed.

We measure the value of installation (and the cost of Callbacks) as “Octane.” This is the $T earned per hour of time at installation. Over the years, we have learned that in the countertop industry a good install team should earn $T at about $700 per hour of their time. This would include travel time to the jobsite and installation time at the jobsite. In an eight hour day, a good Install Team should earn about $5,600 in $T for the company.

This means that when an installation team must spend time dealing with a job that was not completed on the first trip, it is not earning the $700 per hour that it should be. If it took an hour in drive time and an hour to complete the job, that is $1,400 in lost $T for every Callback, every day.

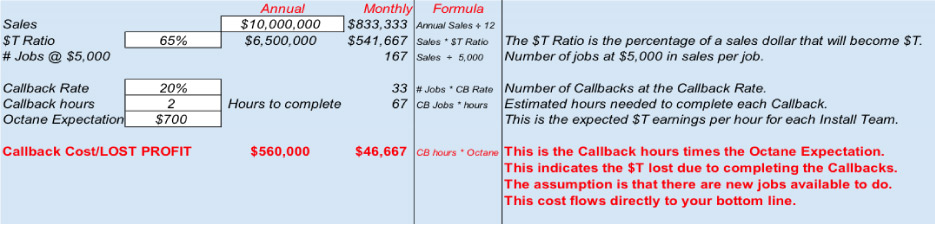

As an example, if your annual sales are $10,000,000, your $T value would be about $6,500,000. At a sales value of $5,000 per job, you would sell about 167 jobs per month. If your Callback rate is 20 percent, you would return to about 33 jobs per month.

Assuming each Callback takes two hours to complete and at an Octane value of $700 per hour, this example suggests you would lose about $560,000 per year due to Callbacks. Note that this is lost value to your bottom line – essentially lost profits.

And, that example does not consider the other negative factors concerning Callbacks such as customer dissatisfaction, lost goodwill, disruption to the schedule and added chaos to your organization.

Substitute your numbers in the white cells in the chart below and calculate your true cost of Callbacks. Consider the impact on your bottom line if you could just cut it in half.

The Solution

First, know what your Callback rate is. Track it daily and accumulate that information over every month of the year.

Drill down to the true core causes of those Callbacks and analyze the data over time. Deal with the chronic causes first. Take only a few targets at a time and take aggressive proactive actions to prevent their reoccurrence.

Drill down to the true core causes of those Callbacks and analyze the data over time. Deal with the chronic causes first. Take only a few targets at a time and take aggressive proactive actions to prevent their reoccurrence.

Know the quality and the quantity of the work leaving the shop. Check both every day. Develop the confidence that when those install trucks drive away, they can complete the jobs on the schedule and without undue extra effort (and time).

Accordingly, make sure jobs are completely ready each morning for the install teams. A delay of one hour to wait for the last pieces to be finished is lost $T at the same Octane Rate of about $700.

Consider an Installation pay system that compensates install teams only for completed jobs. Typically, subcontract installers are more productive and they have a lower Callback rate.

That is because typically they are paid only for completed jobs.

You can do that with your employee install teams, too. It takes a cleverly designed system and compliance with your state’s Wage & Hour regulations, but such a plan will dramatically increase productivity and decrease Callbacks. The Callback costs apply to both employee and subcontract install teams.

Reducing the curse of Callbacks should be a focus for your company. The opportunity to improve your bottom line is significant.

For more information on this or other Synchronous Solutions topics, visit www.SynchronousSolutions.com or call Ed Hill at 704-560-1536.