WF Meyers: Reinventing After 130 Years

Shannon Carey

Photos Courtesy WF Meyers

|

|

Above: Alex Barnes, WF Meyers president, has made great strides in updating the company. |

|

|

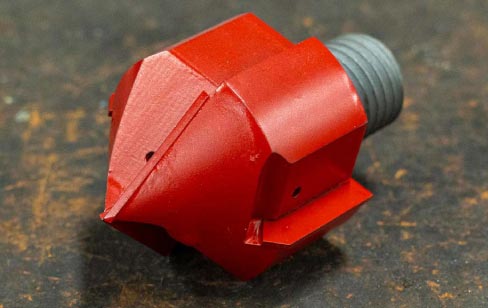

Above: Polycrystalline diamond (PCD) CNC tooling is just one of the new product lines WF Meyers has developed. |

|

|

Above: Diamond wire belt segments are made in-house, and the WF Meyers team helps select tools that are best-equipped for specific stones, maximizing speed and equipment life for their customers. |

|

|

Above: WF Meyers makes a variety of large-format blades for quarry and block saws. |

|

|

Above: Slabbing Saw |

|

|

Above: PCD Tooling for CNC machines |

|

|

Above: Testing a block-boring bit on limestone, on a Northwoods CNC machine. |

The professionals at WF Meyers are experts on diamond tooling, quarrying and slabbing equipment, and more. And with 130 years of history behind them, why shouldn’t they be? Started in 1888 in Long Island City, New York, the company moved to Bedford, Indiana, in 1911, and they’ve been at home there ever since.

But the recession hit WF Meyers hard, and old problems compounded the issue. Who better to “right the ship” than a member of the WF Meyers founding family? Alex Barnes, the fifth generation of the WF Meyers family and now president of the company, stepped up to the plate and made changes that saved the family legacy.

Accepting the Challenge

WF Meyers was founded by Barnes’ great-grandfather on his mother’s side. He grew up in and around the family business, working there during the summers. But he never intended to make WF Meyers his career.

Barnes got his undergraduate degree from Notre Dame, taught middle school for three years, and earned an MBA from the University of Colorado. After that, he didn’t have a new job lined up, so he came to WF Meyers to help out.

“I went to looking around and thought, ‘I just spent two years learning how to run a business. I think I can do some good with that. I can help my folks turn things around. There is a lot of opportunity for improvement here.’” he said. “I like a challenge. I like a turnaround.”

Barnes came on board full time in 2011 and took a hard look at methods and processes. Some of them, he said, were outdated. He looked for efficiencies and ways to modernize.

“We started with improving the physical layout of the plant. We consolidated two buildings into one. I mapped the flow of our parts through the shop and cut the distance that parts travel by half, maybe more,” he said.

Barnes brought new systems and equipment into the office and manufacturing sides of WF Meyers.

“I’m pretty excited about the new functionality of the new CNC Lathe, and things we can do with this piece of equipment. It gives us more control over the tools we make,” he said.

He also reached out for help, bringing on a part-time vice president of sales and a part-time chief financial officer as consultants.

“They do great work for us,” he said. “I’ve got these guys to lean on. They’ve got 30-plus years of experience.”

Another resource for Barnes has been joining a peer-mentoring group, “which I would recommend to anybody who’s running a business,” he said. “It’s been refreshing to me to just be able to bounce something off somebody in a different industry. It took me a couple of years to realize how much I didn’t know.”

Fixing Problematic Products

Developed and patented in the 1980s, WF Meyers’ quarrying system is widely used in limestone quarrying, and an updated belt has made the system stronger and easier to manufacture.

But Barnes said an equally well known WF Meyers product is the company’s slabbing system, “but maybe not always in a good way.” The system’s belts had a tendency to twist, “and that has been a problem ever since the technology came out in the late ‘80s, early ‘90s,” he said.

But under Barnes’ leadership, the company has proactively addressed the problem, throwing out the old belt design and starting from scratch.

“To come up with it was kind of an interesting process,” he said. “We batted around ideas in-house. We don’t have an R&D team, but we have a draftsman. We sat down and said, ‘Look, let’s get serious about making this product work.’ We went from one cable to a multi-cable design. When it was time to test it, we partnered with five local mills and gave them belts to try on the condition that they give some feedback, and it went great. After we had five belts running and people seeing better performance than in the past, we rolled them out as a product.

“It’s worked great so far. We’re getting great reviews from customers. Things are looking up from what was a problem product line for us. Public perception was that our belts were one of our weaker product lines, but I think slowly, as people are willing to trust us, they’re seeing some benefits to doing so.”

New Product Lines

While they’re busy improving old products, WF Meyers is also rolling out new offerings.

Barnes said one of WF Meyers’ “up and coming product lines” is polycrystalline diamond tools for CNC machines.

“We’ve seen remarkable growth on that over the last five years,” he said. “I would attribute it to the industry starting to embrace CNC technology. I think as people are moving away from planers, and carvers become harder to find, I think that people turning to CNC is kind of the next answer to that question.”

In 2019, WF Meyers will roll out diamond wire for the mill.

“We want to be a complete source for our customers,” said Barnes. “I think that we’ve got the ability to offer a good product there with some advantages over some suppliers with lead times, etc. Based on our location, if you’re running diamond wire, it’s easier to send it to Indiana instead of overseas.”

WF Meyers has a standard line of CNC tooling that the company keeps in stock, but Barnes said they’re working on expanding those offerings, too.

“We also have the ability to do custom tools,” he said. “Our in-house draftsman does a really good job on that. Our new lathe gives us the ability to do custom tools without relying on outside vendors.”

Looking for Feedback

Barnes set a goal for the upcoming year. He wants to visit more customers in their shops and get their feedback about products currently offered and products they’d like to see.

“I think it’s my job to be an ambassador for this company,” he said. “One of the things we like to talk a lot about, especially on the sales side, is that we’re not just a parts vendor. I like to see us as a strategic partner to our customers. We’re not so much in the diamond tooling business as we are in the problem-solving business.

“We’re here to partner with you to solve your problems. That’s the company I want to work for. I like a challenge, and I like for things to work smoothly. I think that you can buy diamond tools from a lot of places, but if you want to try something different, let us know. The good ideas come from the people doing the actual work.”

That philosophy goes hand-in-hand with the changes Barnes has made at WF Meyers.

“I think this has been a weakness in the past and something we need to work better on. In the past, the thought was ‘no news is good news.’ I think that’s a really dangerous way to do business.

“One of the ways I like to describe WF Meyers is that we’re a 130-year-old startup company. We’ve been in business for a long time, but we’re in the process of reinventing ourselves. There are a couple of great products we developed, and I think we got a little complacent. I don’t think that was to anyone’s benefit, us or our customers.”

But most of all, Barnes wants to build a relationship of trust with all WF Meyers’ customers.

“We’re taking a little bit more of an active role in partnering with folks,” he said. “That’s where I want to be. I want people to know that we’re here to help.”

For more information, visit www.wfmeyers.com.