Stone Restoration and Maintenance Corner: The New Install Repair Blues

Bob Murrell

M3 Technologies

Photos by Bob Murrell

|

|

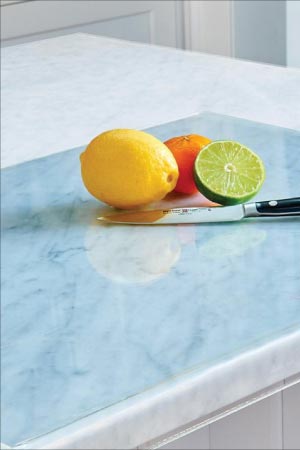

Yes, you can cut fruit and veggies directly on stone, but why ruin your knives, and why risk damaging that $5,000 countertop? |

|

|

Above: Scratching from sanded grout. |

|

|

Above: Scratching and etching on this just-installed inlaid marble floor: it’s enough to make tough installers cry. |

How many times have you received a call from a potential client regarding issues with their new or recently installed stone? If you haven’t gotten one of these calls – you will. Hopefully, most natural stone kitchens, baths and floors are being installed by qualified stonemasons. Some, however, are not so qualified.

Sanded grout, excessive lippage, and just plain poor installs are becoming more common because clients use unqualified installers, possibly to save a few dollars, or even possibly because the installers convinced them that they were qualified. In any case, I have heard from multiple restoration contractors that they are indeed seeing more and more of these type issues relating to a new install.

Of course, there are also other “aesthetic” issues, too. I have heard from many a client regarding some spots on their floor or countertop that happened during the install, only to find out that these “spots” were natural inclusions in the stone. Once again, these types of mistakes are generally caused by a lack of experience from the installer.

Explain Natural Features

When a good installer notices a particular tile or piece with a potentially unacceptable natural inclusion(s), they should inform the client and offer to use another piece. The same is true of the fabricator when using slabs for countertops, islands, and vanities. This is true, even if it causes more waste on a slab or an additional slab is required. Of course there are those inclusions which, in my opinion, make the piece desirable, unique, and add to the beauty of the material. Natural inclusions are some of the features that distinguish natural stone from tile and carpet, right?

And then there are the mistakes that clients make just after the install, especially like etching. So much marble is being installed as kitchen countertops in today’s market, etches are the perfect example of an easy-to-make mistake. Polished marble kitchen countertops are basically prone to damage, and yet we see them fairly often today. Even honed marble countertops and vanities show etching, to some degree. Accidents do happen, but you can pretty much rest assured that these clients have no understanding of their stone and/or how to properly protect and maintain it.

I have seen etching on a newly installed marble countertop just recently, in fact. The GC called one of my clients in to repair some scratching that took place during the install (and some etching the homeowner had also already caused). I accompanied the restoration company to help evaluate and give recommendations.

Some scratching and etching on the center island had been repaired the week before, and this was the restoration contractor’s second trip to the home. On the first trip out, the homeowner was instructed not to cut on the marble and try to avoid contact with acidic products on the marble, as well.

On the second trip, we immediately observed that the homeowner was cutting up limes on the marble island for her spritzer water, right in front of us! It was instantly apparent this homeowner would be telling their GC to come back to fix these types of issues for a long time. “What we got here, is a failure to communicate… some people you just can’t reach!” (I’m showing my age now with quotes from the movie Cool Hand Luke.)

Why Risk It?

Use of an acrylic cutting board is highly recommended for kitchen countertops, even on granite tops. (I mean, why not?) To be honest, even if the installs are well taken care of, they will eventually need some type of stain, etch, or scratch removal, especially if the install is polished marble, limestone, or another of the chemically sensitive, soft, or porous materials.

Now, what about the materials themselves? We have previously discussed many materials such as quartzite (or not), serpentine (green marble), slate and imitation slate, limestones (including travertines), granites (including the blacks like basalt, gabbro, and anorthosite), quartz or engineered stones, decorative concrete, Corian and other similar hard surfaces, soapstone, and many others. These materials all have a useful application, but it is up to us to help assign their place in a residential or commercial setting.

There is a reason that granite countertops have become the norm in kitchens and prep areas. They resist chemical attack and scratching much better than softer calcium-based materials. If your customer prefers marble because of the color and veining, consider a honed surface instead of polished, especially for prep areas.

Another issue that has been rearing its ugly head, lately, is the rise in use of sanded grout. I have seen this in at least four recent floor install situations where scratching takes place just by the normal use of troweling and cleaning up of the grout. Excessive lippage can make this scratching problem worse.

In these cases, the grout manufacturer actually claimed on the bag that it was safe for marble and other dimensional stone applications! I am still investigating this, so suffice to say that no sanded grout should ever be used on finished dimensionally cut stone, especially polished materials.

Sanded grout makes it very difficult if not impossible for future restorations to take place without the risk of scratching. Also, grout lines of 1/8 of an inch or less do not require sand to strengthen them, as do larger grout lines for certain types of ceramic tiles. So if you are an installer, please make sure that you only use non-sanded grout for any finished (honed or polished) dimensional stone installations.

Repairing Damage

Repair of these etched or scratched surfaces normally entails the use of a 220 grit, 400 grit and possibly higher grit diamonds (depending on the type of stone) to re-hone the affected areas, prior to polishing with 5X, Marble Polishing Compound or perhaps even a product like XXX Shine.

Once the stone has been properly restored, please try to educate the client to help them minimize future avoidable issues. Also, I highly advise impregnating/sealing all grout (except epoxy type) and surfaces (especially honed or textured) to reduce foreign contaminant penetration. Develop a maintenance plan that includes both products and procedures. I advise contractors to leave behind a quart or so of the No-Rinse Neutral Cleaner, along with a spray bottle. It will make a good impression with the customer, help them care or investment properly, and is the professional thing to do.

As always, maintain a good relationship with a distributor of quality products and the technical support to back them up. It makes your job much easier.

Bob Murrell has worked in the natural stone industry for over 40 years and is well known for his expertise in natural stone, tile and decorative concrete restoration and maintenance. He helped develop some of the main products and processes which revolutionized the industry, and is currently the Director of Operations for M3 Technologies.