How to Set a 5,760-Pound Countertop

Mark McMunn

Photos Courtesy Mark McMunn

This article actually describes the installation of a massive altar top for a Catholic Church, but it’s a top, all the same. The top in this case history has the impressive dimensions of 8 feet by 4 feet by 1 foot thick. It was made from “Botticino Classico,” a beautiful dense marble from Italy, and weighs right at 180 pounds per cubic foot. The math reveals a weight of 5,760 pounds – just under three tons!

The following series of photos show how the crew from US Stars, a rigging company based in San Antonio, solved the delicate process of moving and installing a multi-ton piece of stone. As you will see, such a project takes the right equipment, the right crew of experienced workers and should not be attempted by the faint of heart or amateurs. To be very clear the description of the process is not meant to be an instruction of how to perform this work yourself, but rather to illustrate that you should know when it is time to call professionals like US Stars to ensure that the work is done safely. In the case of this particular job it was clear that the task needed to be done by a firm that had the known capabilities to perform the task.

The Task: to move a crated altar top from the ground and then up about 15 feet into a narrow side door and required the piece to be lifted to an upright position in order to fit through the door. After the crate was inside the door, the piece had to be moved while still in the upright position to the front of the altar space where it would have to be laid down flat. After carefully lowering into a flat position, the piece still needed to be lifted about three feet and moved forward onto the platform where the altar base was waiting, which was yet another three feet high. Follow along with the photos to see how this was accomplished.

It took a crew of 10 men 17.5 working hours to accomplish this task. There were more stop, starts, backups and outright start-overs than are shown in the photos. These types of tasks in the stone business are few and far between, but you must be prepared to think on your feet and think way out of the box to get the job done.

This type of work also requires a tremendous amount of foresight to anticipate any contingency and to be prepared for it. It also goes without saying that you must be EXTREMELY careful and move slowly when handing great weights, and when the piece is in motion there is no room for horseplay or joking around. You must make sure that everyone has room to quickly escape if the piece or rigging should suddenly collapse and fall.

Take what you can from the photos here if you decide you want your company to move into this segment of the industry. For safety’s sake, have the humility to know when you need outside help and call a capable firm to help you. I hope you have enjoyed seeing these great photos of a challenging task close up.

|

|

Step 1: The crew from US Stars using a 10,000-pound capacity SKYTRAK to lift the crated top off the ground. |

|

|

Step 2: Carefully moving the crate from the yard towards the building entry point. |

|

|

Step 3: Using nylon straps in the choker position to lift the crate into the vertical position. |

|

|

Step 4: Crate is now vertical and aligned with the side door entry point. |

|

|

Step 5: The first misstep. We had to back up and uncrate the piece before entering the building. This required going all the way back to placing the crate on the ground and starting over, and we lost about an hour and a half of progress. |

|

|

Step 6: When we got the piece uncrated we realized that brackets were needed to keep the stone vertical after release from the SKYTRAK. The metal brackets were fabricated / welded on site with channel iron, and took several hours. |

|

|

Step 7: We put skates under the vertical support brackets and wheeled the piece into the building after unstrapping from the SKYTRAK. |

|

|

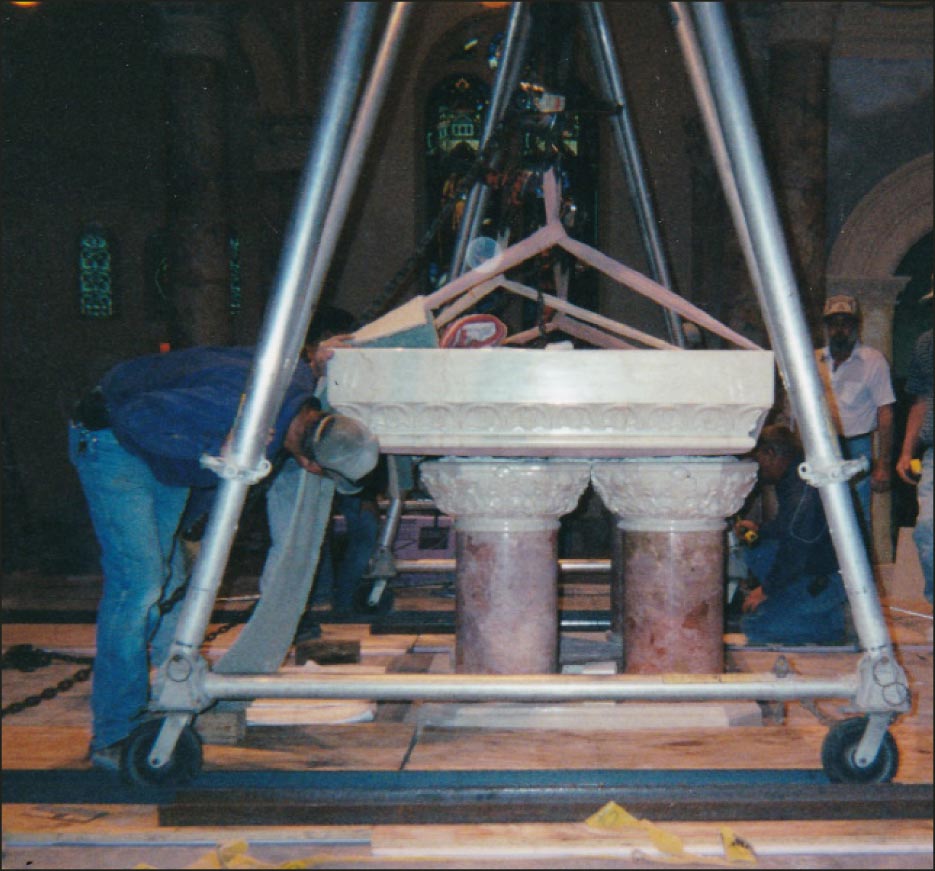

Step 8: After getting the piece into position in front of the altar and laying the piece down in the horizontal position, a rolling A-frame with a 14-inch aluminum I-beam and chainfalls were used to hoist the piece high enough to come over the top of the waiting base of four columns..Look closely and you will see that the wheels are being kept straight by a track made out of channel irons. Its important to remember this technique, as carrying such a heavy load on an A-frame support is very hard to manage and unwieldy. This task marks the end of day one of installation. |

|

|

Step 9: The piece is being moved forward over the top of the four column supports. Everyone in the photo is holding their breath at this moment! |

|

|

Step 10: All are breathing a little sigh of relief as the piece is now above the support columns. Everyone is busy centering the piece onto the column base. |

|

|

Step 11: We have to back up a little bit, but we are almost there. The altar top was centered just minutes after this photo was taken. The chainfalls are slowly ratcheted down until the piece is resting on the base. Large rubber mallets are used to tap the piece into its final centered position. |

|

|

There’s a big sigh of relief and satisfaction as the piece is now set in place. The task was completed at the end of the second day, a total of 17-1/2 hours of careful maneuvering. It bears repeating: you must be EXTREMELY careful and move slowly when handing great weights, and when the piece is in motion there is no room for error or joking around. |