The Stone Shark by Stone Pro Unveiled at TISE 2018

Twelve years ago, Stone Pro Equipment introduced a handy-dandy tool called The Rock Doctor. When used on the jobsite, The Rock Doctor gave the installer the ability to level excessive countertop seam warping.

|

|

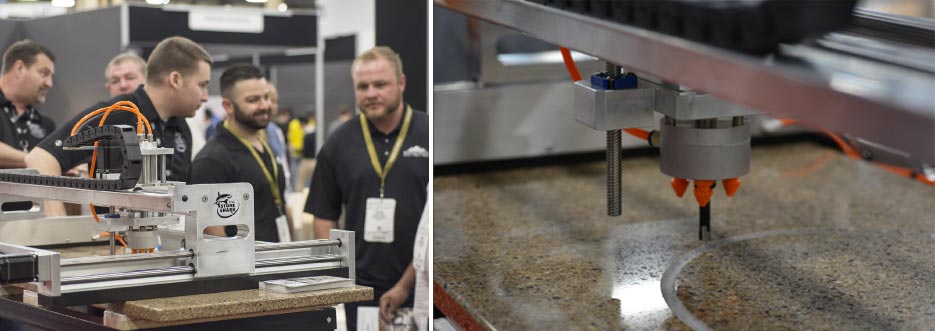

The new Stone Shark received considerable interest at TISE 2018. Here, the portable unit is demonstrated by Brad Winn.

|

Fast-forward to 2017, when another bright idea came to Stone Pro Equipment CEO and designer, Barry Brandt. After seeing a miniature CNC being used in the wood industry and then reflecting on the success of the Rock Doctor, the concept came to Brandt to develop a machine to perform precision sink and range cutouts: the Stone Shark.

With the Stone Shark, you simply set and forget it after placing it on the countertop, locking it down, selecting the correct cutout and depth and hitting the switch. It’s easy to operate and easy to move, said Brad Winn, of Stone Pro. “The Stone Shark is a light weight, easily mastered small-scale machine designed for smaller shops that fabricate by hand, and can take the place of the larger CNCs that larger shops use.”

The Stone Shark is also penny-wise, added Winn. “We’ve done extensive testing, and you’re going to get two and a half to three sink cutouts per bit. The cost of these bits is nothing compared to the cost of the bits used with large CNCs. We’ve introduced a soft stone bit and a hard stone bit, so hard materials like Violetta or quartzites shouldn’t be a problem.”

One important final point: this portable, 120 pound jewel is available just in the nick of time to help smaller shops conform to the new OSHA silica standards. Think of it! When used in conjunction with an edge profile router, the Stone Shark can really help get your dust level down to an OSHA acceptable level! And if your shop is already wet, it seems to me that when needed, the Stone Shark could be a huge asset to the owner who is caught between a rock and a hard place on whether to purchase another large CNC machine, or just scale back production to a more manageable level. Instead, these owners could now defer this purchase indefinitely.

|

|

The Stone Shark’s small footprint and portability make it the perfect tool for automating the sink cut-out process. |

Features Include:

- Easy to learn and operate

- Mobile design requires only a little space to store when not in use

- Electrical requirements: Uses standard 110V 20 amp service

- Vacuum cups keep it locked to the surface of natural or engineered stone

- Drills holes for fixtures

- Made of rugged machined aluminum and stainless steel

- Will step-cut any sink or range configuration up to 36 inches wide

- Using Stone Pro’s incremental cutters ensures longer tool life

Benefits:

- Uses software that easily converts a DXF file into a physical file

- Saves hundreds of cut out template files

- Allows shops to work more efficiently with much less dust

- Cuts sink cutouts with a perfect 90 degree edge, reducing time spent polishing

- Does sink or cooktop cutouts on any depth countertop

- Provides consistent cutouts every time

- Financing available

Specs:

- Only 120 lbs

- 54 inches wide x 36 inches deep x 18 inches high

- Center water-cooled 2 HP spindle motor

- Takes a 3-GPM standard garden hose connection

- Air: ¼ inch female

- 110v 20-amp service

The Stone Shark is available from Braxton-Bragg. Call a sales representative at 800-575-4401 to let them further explain how the Stone Shark can rock and roll your cutouts and profits! Visit Braxton-Bragg online at www.braxton-bragg.com .