Family is the Cornerstone of J & J Stone Fabrication

Peter J. Marcucci

Photos Courtesy J & J Stone Fabrication

|

|

Above: 3cm Light Emperador marble vanity with ogee edge |

|

|

Above: Mitered quartz waterfall island installed in a new residential project. |

|

|

Above: 3cm Juparana Persia kitchen: countertops and full-slab island with ogee edge, and a custom tile backsplash. |

|

|

Above: Home spa with sunken garden tub with marble surround and a custom tile and terrazo floor. |

|

|

Above: 3cm Juparana Persia with ogee edge was used throughout this kitchen. |

|

|

Above: This modern kitchen uses Viatera Rococo quartz countertops and the full height splash to add light and contrast to the rich woods in this upscale project. |

Be it family or extended family, both have taken J & J Stone Fabrication from its very humble beginnings to its present level of success.

Located in West Monroe, Louisiana, the company began in the minds-eye of founder and president James Rogers, but only after traversing a few stepping stones, recalled daughter Amy Chandler.

“Dad was a tile setter and began doing stone work back in the 1990s. When I was just a little girl, I remember him carrying eight color samples around in a little box in his truck. He would have any marble work fabricated in Dallas, and then install it in some of the homes in Monroe, which was very new back then. Later, in 1997, there was a company in Greenville, Mississippi, that needed a person to oversee their fabrication, and they offered him a job. He had four kids, teenagers and younger, and we all moved up there for seven years. It was here that he learned how to fabricate using large machinery.”

According to Amy, after seven years, James Rogers decided to move back home to the family farm located in Start, Louisiana, wanting to create a business that son Josh could come home to and be a part of.

“Josh had been on a church mission for a few years and was coming home that September. So the company started out very small in our barn in June of 2005, giving Josh a job to start when he got home.”

J & J Stone Fabrication serves a 90-mile radius around West Monroe. This extends from the Mississippi river to Shreveport, and from the Louisiana border down to Alexandria, Louisiana: basically the entire north of Louisiana. The company employs a crew of 12 full-time employees, including family members James Rogers (still at the helm), Amy, Josh and Adam. That said, it’s the extended family members that are the backbone of the company, according to Amy.

“If it wasn’t for our employees, we would not be able to do half of what we do. Right now, we have some of the best people we have ever had, ever! For some reason, over the last year, the Lord has shined on us and given us some exceptionally hard-working, intelligent people, and we would not be where we are without them.

“I do most of the sales and talking to contractors, while dad is the president and mostly helps get the jobs completed. My brother Josh is our main installer and takes care of anything we need on the jobsite. He is also our go-to person. Our brother Adam, who is our computer genius, does our CAD drawings. He taught himself and has been a huge asset for us moving towards CNC production. Without him, we would not have been able to do this. Typically, anything that someone would have had to go to school to learn, Adam has taught himself how to do. He’s amazing!”

J & J Stone Fabrication’s equipment consists of an Intermac CNC, Matrix bridge saw, Park Industries Pro-Edge and a radial arm polisher, said Amy, adding, “There was a company in town about five or six years ago that was trying to get rid of an Intermac CNC machine. It was just sitting in their shop taking up room, and they didn’t want it anymore. We bought it, and Josh took that machine, without any training from Intermac, and put it back together and made it work. He did, however, talk to the company at the time, and they were very helpful.”

Production is a 50/50 mix of natural stone and engineered stone, mostly 3cm for the company’s mid to upscale residential clientele.

“We do a lot of large residential,” continued Amy, “and we’ve been making our own shower pans out of engineered stone on our CNC rather than ordering them. We can now do showers without all the prep work, and they are waterproof. Our CNC creates the slope and drain and then cuts it out. I would really like to do more of these. It’s a nicer look, lasts longer than cultured marble, and I can do it for the same price as cultured in certain colors. That Intermac has really been a major asset to us, letting us do things that other area companies don’t do.”

According to Amy, due to the recent purchase of a laser templator from ETemplate, their next planned purchase is a CNC saw.

“A saw person is the hardest person to teach, because they have to see so many things. But if we had a CNC saw, the slab would already be laid out and just cut, rather than thinking about how it needs to be cut. Around here, it’s really hard to find someone that knows how to cut.”

Aside from one other company, J & J Stone Fabrication has been in business longer than anyone else in their area. Priding themselves for knowing the products better than most other companies, they also have a keen sense for knowing what customers want and where to get it, explained Amy.

“When a customer comes to me, I know what they are talking about. I stock a lot of colors and, if needed, I can find exactly what they are looking for elsewhere. I.G.M. in Atlanta, Georgia, usually visits me on a weekly basis, and I’ll just have them send the material to me if a customer wants it. Carolyn is my favorite person to deal with there. I also buy from the Verona Marble Company in Dallas, Texas. What I like so much from them is that they have a really nice website that shows their inventory. The pictures are high resolution, and I can sell the slabs to the customer that way. I can get them here quickly, too, and can always send them back. So we continually strive to produce a great product and to go the extra mile to get the customer what they want.”

Customer wants include fireplaces, furniture and showers as well as a full line of multi-edged countertops. Clients can choose from an array of samples when stepping in to the company’s large, well-appointed showroom. “We have a wall with a lot of slab and tile samples, and an island with a large sink,” continued Amy. “If it can be done with stone, I love to say that we can do it. I don’t, however, want to be the lowest priced company around. We’ve got a few of companies in town that thrive on those kinds of jobs; you know, $27 to $32 per square foot. We are not that company, and we don’t want to be that company. We are the company that when you come to us, we will give you a good product made with good material, and if you don’t want me to do it, you are going to have to go somewhere else. But you will come back — most of them do.”

Amy’s Outlook for the Coming Decade

“We have grown in a lot of ways, and not grown in a lot of ways. We made it through the recession, which was good, but it was tough around here for awhile. We made it through because we make a quality product, we are honest, and we take care of our customers in a way that I would want to be taken care of. Fortunately, this year, I’ve seen more growth, especially in cash flow, than ever. Our company is about having happy customers that want to come back, and it’s that part that makes me feel better than even the money part. That’s how I do business and why I take more time with the customer.

“Furthermore, we have a larger number of contractors, designers and walk-ins coming in to see us. We don’t cater to commercial work. We’ll do it, but we don’t like the cookie-cutter commercial world. We are more of a custom company and would much rather build a custom shower or kitchen. That is our bread and butter and where we do our best. We don’t advertise and have made it through by word-of-mouth. If we did advertise, I’d be kind of scared to see what would happen! I don’t think we could handle that production workload, right now! But we are at a point where we are doing better than we have ever done.

“We had a flood here last year, and as a result there were a lot of new companies that popped up; some came here from Shreveport. So there’s a lot of competition, but there’s enough work to go around because there is a lot of building going on. Something that we do that other companies don’t do, and we are good at, is restoration, including the re-polishing of floors. Josh is amazing at taking stone and making it look new again, and that is an avenue that we would love to get fully into, but we really don’t have the manpower to do it at the moment.

|

|

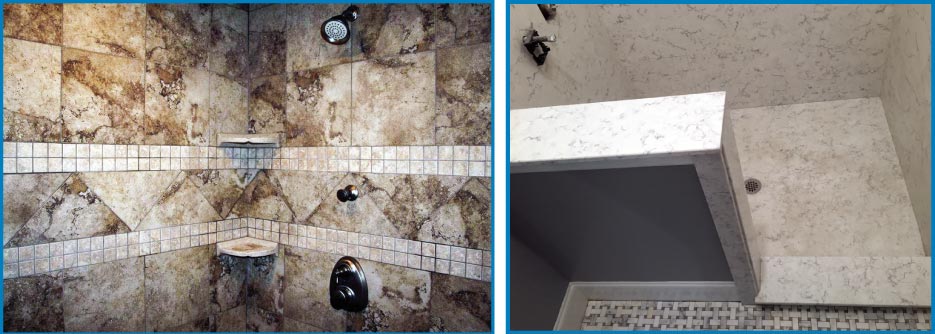

Above Left: Light Emperador Marble Tile Shower. |

“So, our future is looking just great. I see a lot of new avenues to explore and some expansion. I see us doing more work than what we are doing now, and we are moving to two full-time installation crews by the end of the year. I don’t know why we work together so well, but the driving force for us is keeping this business together and doing what we do to provide for every one of us and our families. We are all about family and unity, and what we do between all of us is for our kids.”

J & J Stone Fabrication is a member of the Northeast Louisiana Home Builders Association. The most recent notable project is the renovation of the former Virginia Hotel located in downtown Monroe, Louisiana, supplying all countertops and window sills. The six-story building, constructed sometime in the mid-1920s, originally housed the Louisiana State Office building. It is now the home of Vantage Health Plan Incorporated. For more information on J & J Stone Fabrication, visit their Facebook page: www.facebook.com/pg/jandjstonefabrication/.