New Product Review: Stone Pro Rock Jockey

|

|

With the Rock Jockey, picking up and moving a slab in the shop is no longer a two man job. The Rock Jockey attaches to your boom and is operated by an easy-to-use remote, giving one person — the operator — complete control of slab rotation and placement. There’s no need for a second person to do the most risky job in the shop – walking along side and guiding the slab. The Rock Jockey eliminates one of the most dangerous and potentially fatal jobs in any fab shop. |

Stone Pro Equipment, a name synonymous with timesaving inventions for fabricators, has come up with the next generation of safe slab handling. A glimmer in the eye of stone fabricators (including me) for decades, Barry Brandt and the brilliant minds at Stone Pro Equipment have managed to flesh out a long awaited device which they have dubbed the Rock Jockey.

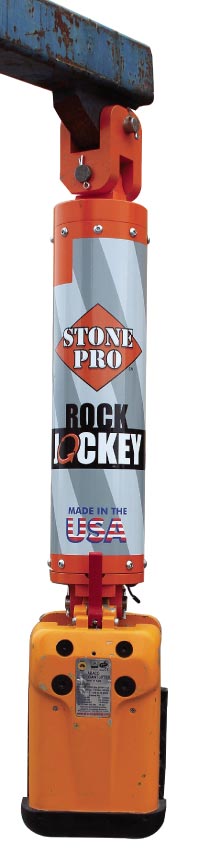

What It Is: The Rock Jockey is a radio controlled, motorized, 360 degree steerable swivel that attaches between a boom and slab clamp. Once attached, a single forklift operator can safely pick up a slab, trundle though the tightest shop and place it anywhere, a task that usually takes a two- man team. With the Rock Jockey, there’s no handler needed on the ground to guide the slab; with this device, no handler need ever get hurt again! Moreover, it keeps a volunteer fabricator where he belongs: fabricating. Are you thinking less Workman’s Comp, no OSHA visits, yet?

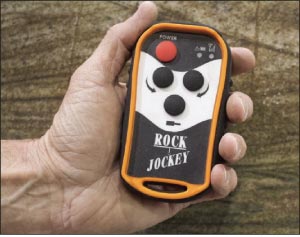

How It Works: The Rock Jockey easily attaches between any forklift boom and an Abaco 50 or standard Aardwolf slab clamp. Once connected, it is easily manipulated through the buttons on its magnetic backed, palm-size remote. Simply chock the slab, pick it up, and left or right 360 degree rotation is just a button away.

When arriving at your slab’s destination, be it a saw, A-frame storage or CNC, simply lower the boom and push the release button. The Rock Jockey is not only safe and user friendly — it even looks like fun to use!

How It’s Built: The business end of the Rock Jockey is all steel construction inside and out, and incorporates a clutch to prevent possible internal damage due to heavy wind or bumping during use. A military grade charge port for its internal 12 volt battery pack bullet-proofs this waterproof package for years of service. A big plus is there’s no routine maintenance needed.

There’s an additional safety feature built in: each hand-held remote is dedicated to only one Rock Jockey unit. This feature allows for multiple Rock Jockey units to operate in close proximity with other units, without interference. To conserve power, the remotes shut off after 10 minutes of no use. And with the exception of the battery pack, the Rock Jockey is designed, made and assembled in America! To me, this one little detail is a deal closer.

How Much Does It Cost? $4,500 will get this jewel to your doorstep, that is, if you’ve got the foresight and gumption to go for it. But why wouldn’t you? The Rock Jockey will keep your labor costs down, keep your staff safer, keep your insurance costs lower and will help to keep OSHA visiting your neighbors instead of you. And incidentally, it will give you a better bottom line.

Where to Get It: From the innovative suppliers at Braxton-Bragg, of course! Watch the video at www.braxton-bragg.com and see the Rock Jockey in action. Then call one of their sales reps. There’s one waiting to help you right now with your questions about this great new device,

call 800-575-4401, 8 a.m. to 6 p.m. EST Monday through Friday.

|

|

The Rock Jockey wireless remote connects to one and only one Rock Jockey, allowing larger shops to use multiple Rock Jockey units.

|