Using the Prodim International Proliner

A Review of the Proliner 7 and Proliner 8 Digital Templating Tools

Peter J. Marcucci

Photos Courtesy Prodim International

|

|

Above: The Proliner 7 has built-in CAD software, allowing an operator to finish drawings in the field. |

|

|

Above: Measuring points for a backsplash can include the cutout for an electrical plate. |

|

|

Above: Prodim also offers a template plotter for those shops not yet using CNC. You simply transfer the information from the Proliner to a plotter that prints out each countertop using Mylar material. |

|

|

Above: The four-hour battery life of a Proliner gives you plenty of time to get the job done when when measure for templates on a jobsite under construction or without AC power. |

|

|

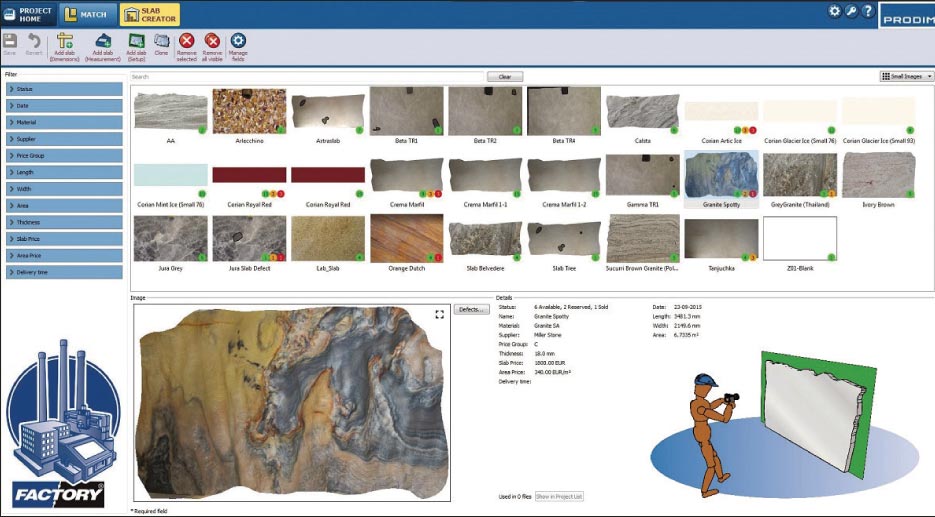

Above: Prodim Factory output showing slab layout. |

Located in Fort Pierce, Florida, Prodim International has been developing digital templating Proliner technology for over 15 years. Currently offering two models, the Proliner 7 and Proliner 8, the company continues to stay ahead of the curve by offering cutting-edge technology, explained sales manager Zach Harris.

“We are always refining our stone industry products. We do sell to other industries, but the stone industry is our bread and butter, and any time there’s a solution needed, we try to be on the front wave of that. Our Proliner digital Templater is a good example of this.”

Features & Benefits of the Proliner

The main difference between the Proliner 7 and Proliner 8 series is that the 8 is used more for 3D measuring, such as architectural work, while the 7 is used for 2D measuring, such as countertops.

Both units come with their own CAD software, allowing the user to finish all the drawings in the field, and then send them back to the shop.

This, said Harris, is one of the biggest benefits. “The Proliner has software built into the system, and you’re able to do all the editing in CAD, even building a job ticket right in the Proliner itself. You can then transfer the file via USB from your phone or laptop. This factor alone is a huge time savings.”

Anyone that’s been in the stone business for any length of time knows that accurate templating is the first step to a more efficient workflow.

It’s where all the good and all the bad begin, period!

“A good digital file is paramount,” continued Harris. “Even before getting a CNC, it’s nice to learn how to create a digital template because you’ve already got the first step down.

Moreover, where it would take one or two hours to template an average kitchen using wood strips, with the Proliner you can do it in 15 to 20 minutes.

So from taking the machine out of the bag to finishing the drawing and sending it to the shop, the time saved is substantial. The savings will add up because you’ll be able to cut out the cost of the wood strips, screws or glues used to assemble templates.

“It also looks more professional on the jobsite. Many customers don’t know what the Proliner is and think it’s a really cool tool. It’s almost a sales tool in itself when you tell the customer that you digitally template.

Also, there’s no need for a truck to haul the wood, the tools, or finished templates. You can transport the Proliner to the jobsite in a small car.”

Proliner Setup

At the jobsite, you simply set the tripod, mount the Proliner, turn it on and start measuring. There is no leveling either, said Harris.

You just basically put it in the best position to measure the complete kitchen and begin, even if the countertops are a full 360 degrees around the Proliner.

It comes with a 21-foot cable, so you have a 42-foot working diameter from one position.

If needed, you can move the Proliner, explained Harris. “It has a built-in reposition function, so if there’s a countertop that you can’t get to from one location, you can easily set up from a different position. The Proliner is a coordinate measurer, so you are actually touching what you’re measuring. Wherever you touch is the exact point the Proliner is going to record, up to 15 thousands of an inch. So the accuracy is far better than other methods.”

Small Shop or Large, All Sizes of Shops Can Benefit

Harris stressed that you don’t need a CNC to take advantage of the Proliner because Prodim also offers a template plotter for those shops not yet using CNC. You simply transfer the information from the Proliner to a plotter that prints out each countertop using Mylar material.

“For the smaller shop, the biggest return on investment (ROI) is the time savings,” Harris continued.

“Basically, you’ll get your ROI within a few months, because instead of going to just one or two jobs throughout the day, one person will be able to template five to six jobs per day. So you’re getting more jobs through, and that will help grow the company.

“For larger shops, the ROI is due to all of the above, plus higher accuracy and fewer mistakes, and the more accurate and fewer mistakes, the more money you make.”

Built-In Software

According to Harris, the software for countertops is basic 2D elementary CAD that uses easy-to-learn symbols. Every time you touch a symbol, the Proliner tells you what it wants you to do next for that command.

It’s tailored to the stone industry, so you’re able to add color-coded radiuses, seams and overhangs.

You can also create your own sink and edge profile library, so for the sinks that you use that come with a DXF file from the manufacturer, you can upload them into the Proliner library and drop them into the drawings.

It’s also easy to double-check all measurements in the Proliner software before beginning production.

Prodim International additionally offers a slick little option for the Proliner, explained Harris.

“We also offer another solution for fabricators called ‘Prodim Factory’ which is used for slab matching. You simply take the digital templates within the Proliner and overlay them on the slab pictures stored in the software’s “digital warehouse.”

Customers can now see and sign off on book matched seams, the sink and backsplashes while you maximize the use of slabs.

“You also have the ability to create quotes using customer drawings. For instance, if someone came in with measurements of a countertop, you could type in those measurements, add the edge and cutout and give a quick estimate right then and there. So the Proliner really is a sales tool as well.”

Battery Power for Jobsites

The Proliner is powered by both AC (wall current) and DC (battery packs), and comes with two battery packs and an AC power supply.

Each battery pack is good for approximately four hours, so you’re good for a full day of templating.

It also comes with a one-year warranty. “If there’s a malfunction due to a parts or software issue it is fully covered under the one-year warranty,” said Harris.

Training

For fabricators buying into the Proliner system, hands-on training is available at their facility in Fort Pierce, Florida, explained Harris.

“Onsite training is usually one day. We have a demo kitchen counter with full height backsplash, a demo shower and a demo staircase. Anything you would need to measure, we have it set up here. After training, if the user has any technical questions, he or she can call our office. Our people know the Proliner inside and out and can help out with any issue that may be happening. There is never a charge for any after the sale support like this. Online training from one of our many instructors is also available. It’s live, one-on-one and usually lasts about three hours.

“The Proliner software and Prodim Factory is a one-stop solution tailored for stone fabricators. We made it that way, so if you have the Proliner you can finish everything on it. The software is easy to update, too. So if you’re thinking about going digital or just want to increase efficiency, the first place to start is by acquiring accurate digital templates using our Proliner.”

For those interested in seeing the Proliner 7, Proliner 8 and Prodim Factory in action, visit the Prodim International booth at the January 2017 StonExpo in Las Vegas or visit www.prodimsystems.com .

|

|

Above: Screen shot of Prodim Factory software, showing a collection of actual slab photos that have been added to the software’s digital warehouse. This innovation allows fabricators to present choices to customers about matching seams and patterns from their in-stock slabs, quickly offer quotes, and also maximize the use of slabs. |