Doing Business “The Park Way”

‘Trust, Integrity and Respect’ Create Legacy of Success

Shannon Carey

Photos Courtesy Park Industries

|

|

Above: Park Industries co-leaders Joan Schatz and Mike Schlough stand on the production floor at Park Industries in St. Cloud, Minnesota. |

|

|

Above: The Park Industries massive, modern production facility spans two large facilities occupying over 100,000 square feet. |

|

|

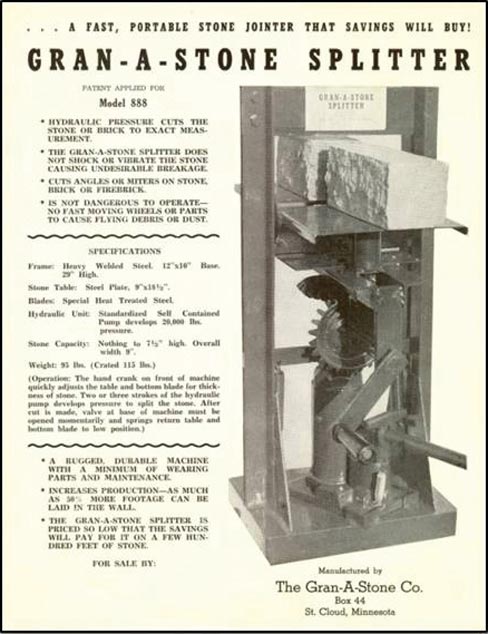

Above: Founded in 1953, Park Industries began by building small hydraulic splitters. |

|

|

Above: Park Industries transformed the thin stone production market by introducing revolutionary thin stone veneer machines, like the patented TXS-2600 Whisper. |

|

|

Above: The Park TITAN® Fab Center combines efficient sawing and accurate edging capabilities in one machine. It is capable of cutting, shaping and polishing 120 square feet with one machine, during one shift, with two operators. |

|

|

Above: Of Park’s associates, 22 percent are located in customer service/support roles. This supports the company’s commitment in providing exceptional customer service. |

There’s a lot of talk about the stone market being a young industry. When all you hear about are companies that got started in the late '90s, just as stone countertops came into high demand, it’s easy to forget that there are companies with legacies that span a half century or more, that were in stone long before it was trendy.

One such giant of the business is Park Industries, which has designed, built, marketed and supported stone fabrication equipment for more than 60 years in its hometown of St. Cloud, Minnesota.

Today, the company’s co-leaders are Joan Schatz and Mike Schlough. Mike is a third-generation Park Industries owner and family member.

Mike’s grandfather Leon got Park Industries off the ground in 1953, making a small stone-splitting machine. In those days, before industry events were available, marketing was challenging.

“You put a machine on the back of a truck and went on a road trip,” said Mike. “It was that way for years and years up until the 80s. I would hear stories of, ‘Don’t come back until you’ve sold it.’”

But even back then, the ethic that would come to be known as the Park Way was taking shape. At its heart is the idea that Park Industries can be of service to its customers, employees and the community, that by doing good the company will be successful.

By placing value on the customer experience and taking responsibility for their product, Park has stayed strong as a cornerstone of the industry.

Bringing the Culture To Life

Mike’s father, Tom Schlough, took on leadership of the company after Leon. Mike grew up around Park Industries, but didn’t join the company immediately after college. He pursued a career in engineering in “corporate America” until he felt compelled to come back home 11 years ago.

Tom Schlough brought Joan on to Park’s executive team 10 years ago, recruiting her from the Minneapolis/St. Paul area. It was the Park Industries culture that brought her on board.

“I never thought that I would work for a family business, nor did I ever think I would work in the stone industry,” she said. “I was really impressed with the culture. It wasn’t just words on a wall. I could feel the difference.”

She could also tell that Park Industries was “the best of both worlds,” a close-knit, family-owned business that was also professionally managed.

“Sometimes family businesses can have some challenges to them. I didn’t find that at Park at all. We are professionally run with an external, independent board of directors. We have the camaraderie and closeness of a family-owned business and the benefits of a professionally run business.”

Joan was also excited to be able to have an impact on the St. Cloud community. Part of the Park Way is community involvement. The company is active in the United Way, over and above embracing an annual campaign. Mike and Joan support the local Boy Scouts and Girl Scouts, and all associates receive paid time for community service.

“We’ve also observed over time that as businesses have been bought or sold out of town, the community connection and the giving back changes dramatically, and you can see it,” said Mike. “When you’re owned by somebody out of town, the importance of volunteering at the elementary school, all that essentially stops.”

“We are very much oriented around service,” said Joan. “If we live in a strong community, that helps us be a stronger business. It’s a virtuous cycle.”

Joan and Mike have a tagline for the Park Way: “trust, integrity, respect.” It encompasses everything about the company, from how employees are treated to customer care.

“I bet we have a conversation daily in which the Park Way comes up,” said Joan. “It truly is our compass that guides how we live out our daily work.”

“Everything we do, we do it the Park Way,” said Mike. “It’s a way to cement expectations and behavior for everybody that we deal with.”

Shaping Stone, Shaping the Industry

That splitting machine that Leon Schlough developed in the '50s was Park Industries’ bread and butter until the late '70s. In the '80s, Park expanded into sawing equipment, then CNC equipment.

“Now, we have a full line of fabrication equipment for the countertop industry in addition to having roots in the larger architectural stone fabrication industry,” said Mike.

One of those, the Pro-Edge, is a Park Industries invention that became, in Mike’s words, “the Kleenex of the stone industry.” It became a household name among stone fabricators and was one of Park Industries’ top sellers until CNC technology came to the fore.

“We’ve sold over 1,000 of those machines,” said Mike. “And it’s fun to hear people talk about a different brand Pro-Edge.”

Park Industries has also received awards for innovation around the Fusion SawJet and was instrumental in the growth of the thin veneer industry, Mike said.

“We have introduced a lot of things that have raised the bar in the industry, and we’re continuing to work on things on that end. We have a research and development space that is jam packed as we speak with new stuff. We are always looking for new ways to help our fabricators.”

And where do many of these ideas get their start? From fabricators, Park Industries’ own customers. Each new product is an answer to fabricators’ calls for improved processes.

“We know a lot of people, and we have groups of fabricators that belong to some business groups that we have formed,” said Mike. “But they’re not for us to influence the members. They’re for the members to collaborate. We get to hear challenges and solutions. We’re kind of the middle group that gets to talk to thousands.

“Running a business is kind of at an evolution right now. Because of the recession, unfortunately we lost a lot of fabricators. People are forced to be more business-minded. The point is that we want to help you invest in your business.”

“Our machines transform their business,” said Joan. “It will transform their shop. It has a much larger impact. By challenging their processes, we are able to help our customers be more successful financially.”

In-House Equals Innovation, Quality, Service

There’s another aspect of the business that makes Park Industries unique.

“We believe that we are the only stone equipment manufacturer in the world that does everything on our own, front to back, from design to sales to after-market support. We have always structured our business in this fashion,” said Joan.

“In the beginning we were very, very small,” said Mike. “But as we grew we began to understand that the best way to serve our customers is to do it ourselves. We have a direct line to the customer without anybody in between.”

To achieve this today, Park Industries employs around 290 associates across a wide array of disciplines. Software, mechanical and manufacturing engineers, designers, installers, sales force, training team, phone and field service groups, manufacturers like machinists, welders and electrical technicians, all and more are part of the Park Industries team.

Every aspect of every machine is assembled in the Park Industries facility with no outsourcing.

“We literally start off with steel and some wires, and out the back door comes a completed machine,” said Joan. “At Park, we are a highly collaborative group with a wide array of skills and knowledge at our fingertips.”

That’s why Park Industries places emphasis on developing their workforce and treating their employees right.

One in five Park employees in each of the last two years has had the opportunity for promotion or a lateral move.

“We are upping the abilities of our workforce all the time,” said Mike. “We are giving them the opportunity to grow personally and professionally, too. It is our hope that because of the culture and values that we instill here that people go home and become better members of the community.”

Park Industries has about 13,000 machine installations across North America, a lifetime service guarantee, 24/7 phone support, and field support. On top of that, they conduct customer training in-house. On any given day, customers are on-site at Park Industries, making the Park Way even more important.

“We have a very complex business, there’s no doubt about that,” said Joan. “But we have really good people that work at Park, and they do a great job at keeping things coordinated within the business and for our customers.”

|

|

Today, Park Industries is the largest manufacturer of stoneworking solutions in North America. |

Looking Ahead

As for the future, Mike and Joan said their goals are not driven by numbers. They don’t want to grow just to be a big company. For them, growth is about improving the industry and helping their customers succeed.

“I think the stone industry is pretty cool and continuing to grow, and we want to grow with it. The satisfaction that we get through the company, working through problems, that’s the icing on the cake. When people say, ‘That’s why I work with you,’ that makes it all worth it,” Mike said. “We want to set the bar for excellence, and whatever that brings, we’ll embrace it. It’s fun to be able to do what needs to be done, to be able to continually set the bar for what being the best means in the community.

“That’s the fun part.”

And that’s the Park Way.

For more information, visit www.parkindustries.com .