Twelve Great Installation Tools Every Shop Should Have

Peter J. Marcucci

Fabricators: If getting your countertops out the shop door is half the challenge, then getting them installed is the other half. How many installations have you ever seen, even with the most accurate templates and cutting, that went in without one single, hitch? I, for one, have never seen it. How about you?

Time consuming issues such as scribing, coring, breakage and unpolished returns are a few of the challenges. Then there’s the harsh weather outside and leaving no dust inside scenario, and while you’re at it — you must make sure you don’t track in any dirt, mar the walls or scuff the woodwork...

Be that as it may, the job must go in, so read on as we suggest 12 great products to help you get it done Faster, Better, and Cheaper!

|

|

TemplatePro T Deluxe Templating Kit |

|

|

Stone Pro Vacuum Template |

|

|

Makita 4101RH 5 Inch Masonry Saw |

|

|

Makita 9565CV 5 Inch Industrial Grinder |

|

|

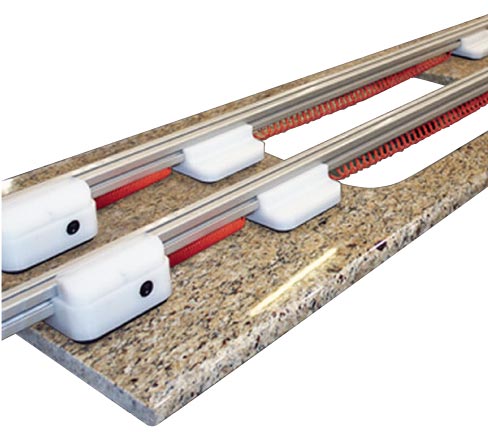

Stone Pro Vacuum Support Rail System |

|

|

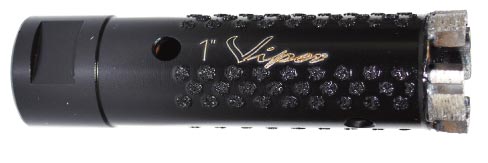

Viper Dry Side Protection Core Bits |

|

|

Elipse 6-Step Wet Polishing Pads and Patented Oscillating Back-Up Pad |

|

|

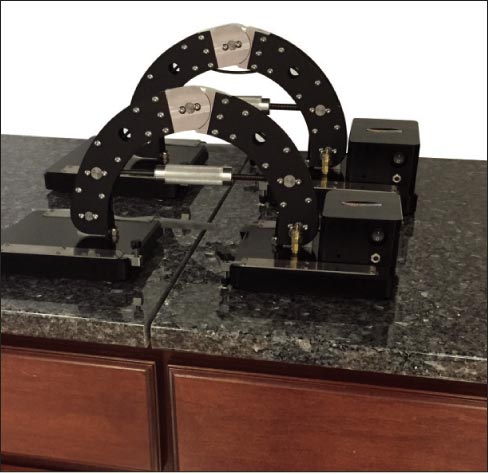

Stone Pro Seam Machine |

|

|

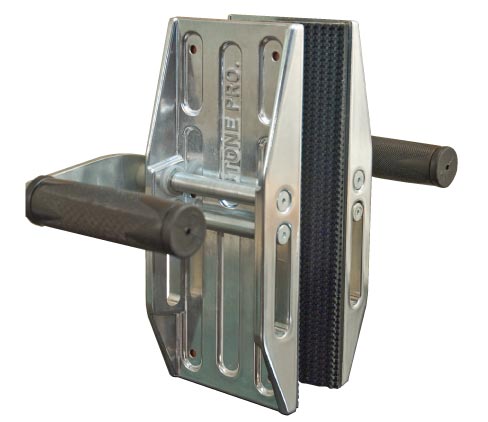

Stone Pro Carry Clamps handle up to 500 lbs and 4 cm thick material – sold in pairs. |

|

|

Stone Shield Knife Grade is fast curing, an excellent choice for your install kit. |

|

|

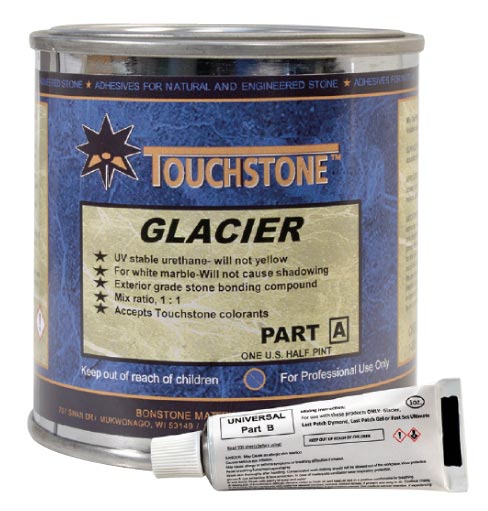

Glacier Epoxy is non-yellowing, and a true water-clear hybrid adhesive for marble. |

TemplatePro T Deluxe Templating Kit

Templates made from cardboard or paper are easily stored, but both can expand and contract with humidity, rendering them inaccurate. The use of wood strips can be accurate–that is, if they’re not damaged during transportation or storage. Enter Fab Quick’s TemplatePro T templating kit — an easy-to-use, easy-to-transport template system that has all the right stuff to get you in, get it accurate and get you out quickly.

Even the largest countertop replicas are easy to transport and store because the plastic templates can be rolled-up. Overhangs are a breeze to template as well, using the supplied overhang clips. So whether you’re a bigger shop laser templating, or a smaller shop looking for better ways to do things, this is very practical product that can save you time and give you the highest professional results!

Stone Pro Vacuum Template

This gem of a tool came about after Stone Pro’s Barry Brandt witnessed installers not only making dust while dry coring fixture holes, but having their bit walk off center when beginning the cut. Something new was needed.

The Stone Pro Vacuum Template attaches to your wet-vac hose via a friction fit cone. You then select the proper size bit insert placing it in the unit, and then align it over your mark. Once aligned and the wet-vac is switched on, the Vacuum Template is sucked down tight to the stone. You’re now able to easily begin drilling while every drop of water is sucked into your wet-vac. The core will fall through, but they’ll be no water or dust anywhere. It works equally well in vertical applications such as walls, too. It’s the quick and clean solution to accurate coring explains Braxton-Bragg V.P. of Customer Service, Steve Bussell.

“While showing this product to onlookers at the last StonExpo trade show, the manager of a fabrication company stepped up and explained that what separated his company from his competitors is jobsite cleanliness and looking professional. Spraying water on the wall or floor or leaving dust everywhere else is not good he stressed.

With this tool, you can go from one hole to the next keeping things simple, efficient and clean. It comes with 6 different size coring inserts that serve as a guide to hold a true 90 degree angle, creating a perfect hole every time. Works great on textured surfaces, too. The Stone Pro Vacuum Template even looks professional and is one of the smartest products we’ve ever sold!”

Makita 4101RH 5-Inch Masonry Saw

Makita has made the 4101 for a long time. It’s compact, cuts through 3cm material like a hot knife through butter, and is extremely durable, as it is made specifically for a wet, dusty environment. “We sell this saw every day,” said Bussell. “Other saws may look similar, but cannot hold a candle to this tool.”

The Saw features include:

- Powerful 7.9 AMP motor for the most demanding applications

- A special cover design that prevents water from entering the motor housing

- It can cut up to 1-5/8 inches (3cm) deep at 90° and 1 inch at 45°

- Lock-on button for continuous operation

- Adjustable depth of cut

- Built-in ground fault circuit interrupter (GFCI) plug.

The Makita Masonry Saw kit includes 15 feet of tubing, a water pressure regulator and water valve.

Makita 9565CV SJS 5˝ Industrial VS Grinder

While other grinders have comparable features, this grinder has become the industry standard and the go-to tool for fabricators everywhere. Why, you ask? Well, it’s the size of the tool as well as its RPM range — slow enough to do dry polishing — fast enough to core drill or cut. The machine holds up well to all of these tasks and is Braxton-Bragg’s top seller, explains Steve Bussell. “We sell a lot of grinders, but at the end of the year, when we look at what’s been popular, we like to say that it’s been the customer that’s made the choice. By far, this solidly-built, dependable workhorse has sold 100 to 1 against similar grinders.”

Stone Pro Combo Pack Vacuum Support Rail System

It is said that an innovator drives development — and a leader sets the pace. Stone Pro is both. Designed to carry any size countertop, this well thought out, well-machined support system was designed to carry even the weakest countertop safely from truck to house.

Bussell explained, “One of the differences of this product is that it carries 8 AA batteries, allowing 8 hours runtime. But the real beauty of this tool is the CNC-style cups that work great on any surface. They hold just as tight to any textured or rough surface as they would to a polished surface. It’s the only support system that I know of that does this!”

Viper Dry Side Protection Core Bits

These core bits flat-out rock! Steve B. thinks so, too: “These ultra reliable bits are our number one seller! They cut clean and fast with minimal breakout, even when coring the toughest stone. Use them wet from 2,000 to 4,000 RPM and dry at 10,000 RPM.”

Viper Dry Side Protection Core Bits come in 9 different sizes ranging from 1 inch to 3-1/2 inches. They will save you time and money, and saved money means a better bottom line for your shop!

Elipse 6-Step Diamond Polishing Pads

For over two decades, polishing pads made of Phenolic resins have been the de facto standard of the industry. They undoubtedly got the job done, and some pads like the Viper and Talon still work very efficiently, but all phenolic resin pads are limited by two things: their ability to hold higher quantities of diamonds, and worse, “diamond dropout” eventually renders phenolic resin pads useless.

Enter the solution that the stone industry has been waiting for: TrifectaMate Technology, a physically and chemically different material far superior to conventional resins, and proprietary to all Elipse pads.

Put simply, the TrifectaMate resin allows a higher concentration of diamonds–more than twice as many, depending on the grit, than traditional pad technology. Moreover, the resin is “stickier” and holds onto the diamonds longer, yielding more linear feet of polish per pad, with faster results.

Additionally, Elipse pads use polycrystalline diamonds — the same diamonds used in oilfield drilling, where a 100% duty cycle is required. They are a little higher in cost than standard industrial diamonds, but offer substantial gains in performance.

Bussell continues, “The word on this product is spreading like wildfire. It’s very positive. The speed that you’re able to do the polishing and how evenly they polish, especially anything flat or beveled, is amazing! For best results when using these pads, we encourage everyone to also use the Elipse Oscillating Back-up Pad.”

One last point: due to the makeup of the patented TrifectaMate formula, the Elipse final polish pad will achieve a superior finish on all materials, even engineered stone, with no worries of color transfer from pad to material. For a polishing demo filmed at StonExpo 2016, see the Elipse Polishing System page on www.braxton-bragg.com. You’ll be impressed by how quickly you can take a rough-cut backsplash to final polish. And for dry jobsites, the Elipse 3-Step Dry Pads for Granite Pads are awesome for installation touch-ups of granite and marble.

Stone Pro Seam Machine

In the past, Stone Pro as well as others made seaming tools that were completely rigid. The only time older model seam setters flexed was if you were pushing or bending the stone. Unfortunately, whenever the stone flexed even slightly, many times the cup pulled loose from the stone.

Unlike its predecessors, the new Stone Pro Seam Machine pivots. Each support arm comes out independently, so when it lifts one side of the stone it pushes the other side down, independently. Not only that, Stone Pro added an arch design to the Seam Machine, so you can get your hand underneath to clean the seam while it’s setting-up. Unlike all other seaming tools, the Seam Machine has no obstructions to prevent you from cleaning. No other seaming tool offers this. As a plus, it works just as well on textured materials as on polished.

Each Seam Machine is an independent, autonomous unit. There’s an independent vacuum pump on each cup, so there’s no hoses to get in your way. Moreover, there’s no power cord, because the power is also onboard. It will run for 10 hours, so if there’s no power at the jobsite, you’re still good to go.

The Stone Pro Seam Machine is made with stainless steel and aluminum, and looks quite “space age,” explained Steve: “The Seam Machine was such a unique looking product at our booth, at Surfaces 2016 in Las Vegas, that we had people, even ones that weren’t in the stone industry, wanting to know what it was. With its arched supports, it almost looks robotic, and it caught everybody’s attention. Each suction pad will handle 800 lbs, and it levels seams just like it’s supposed to. All these features, plus the fact that the clearance of each support arms gives you access to the seam while it’s curing, sums-up why everyone was very impressed.

It’s very effective, well-designed, and a game changer.”

Stone Pro Carry Clamps

Stone Pro Carry Clamps are nothing new; they’ve been around a long time. For the price, they make carrying countertops so easy. Strong and maintenance free, they’ll handle countertops up to 500 pounds and 4cm thick. The hardware is bomb-proof and the rubber is replaceable. This product is a proven performer for carrying in countertops and staging, and the choice of many installers. Stone Pro Carry Clamps are affordable and every installation crew should have them.

Stone Shield Transparent Knife Grade Polyester Adhesive

With strong bonding and excellent polishing traits, Stone Shield’s Transparent Knife Grade Polyester Adhesive is the perfect choice for laminating, patching or filling all types of stone, including engineered stone.

“It’s our most popular polyester and has all the attributes installers look for,” explained Steve. “It is very clear and as strong as any of the high-end polyesters.

People also like the consistency and fast curing time. It works with all color dyes, too.”

Touchstone Glacier Non-Yellowing Knife Grade Epoxy

These days, white marble (especially in the kitchen) has become extremely popular, requiring special adhesives that don’t discolor or leave a “wet look.” That said, standard transparent glues used for adhering laminated or mitered edges to these countertops can cause great disappointment. Luckily, genius comes in many forms — this time it’s in the form of Touchstone’s Glacier Non-Yellowing Knife Grade Epoxy.

“I love this product because it can be used in almost any application,” explains Bussell. “We’ve run into examples where customer have gotten ghosting or shadows from other products when they’re used on white marble such as Carrara or Statuary. Touchstone Glacier Non-Yellowing Epoxy is a true water clear adhesive that sets up quick. You can treat it like a polyester, but it has the strength of an epoxy. So whether it’s hot, cold or damp, inside or outside, you can do stone to stone, stone to glass or stone to metal with no problems. Works great on glass and engineered stone, too! Anything that requires an epoxy, you can use this product in its place. As a plus, the hardener is in a tube (7 included) and is mixed 1 to 1, so there’s no measuring needed. It’s foolproof and without the waiting time of other epoxies. It takes standard polyester colors, too.”

So what are you waiting for? — saved money is easy money, and it all starts by speaking to a Braxton-Bragg representative today or visiting the website www.braxton-bragg.com.