Bonstone Last Patch & Dymond: What’s the Difference?

Mike Beckmann

Bonstone Materials Corp.

|

|

Bonstone Last Patch and Dymond have similar UV-resistant properties, but different curing times and polishing characteristics. Last Patch is suitable for sandstone & limestone, and Dymond, for granite. |

|

|

Dymond has a different “sweet spot” in curing time than Last Patch, and offers a faster, harder UV-stable cure suitable for granite projects. It can even be used to repair polished granite headstones. |

You’ve probably seen (and hopefully used!) these unique patching and restoration products from Bonstone Materials. But you may not be aware of the subtle but important differences between these two product families.

The “original” Last Patch products were developed over 20 years ago to fill an unmet need for a light-stable, non-yellowing, permanent patch material for natural stone–one that would look as good after 50 years’ exposure to the elements as it did on Day One. The Last Patch Gel (for polished and honed fine-grained stones) and the Last Patch Limestone (for coarse-grained stones like limestone and sandstone) met those needs, and still continue to be best-sellers to this day.

The combination of easy-to-use, quick cure, UV-resistance, and inherent resiliency have led to their broad acceptance in the marketplace, and their use on some marquee projects including the Washington Monument and the Longfellow Bridge.

With the ever-increasing pace of life in our hectic United States, our customers are continually asking for faster-curing products. And that’s where the spark of innovation that led to Dymond comes in.

We experimented with variations of the original Last Patch formula to see if we could speed it up to the required level of cure; and it could indeed be accelerated, but we quickly ran into the Law of Diminishing Returns—we simply couldn’t get there from here. So we entered into a lengthy research project to develop a product with the following goals: retain all the desirable properties of Last Patch but find something that would cure harder and faster. And viola! Dymond was born.

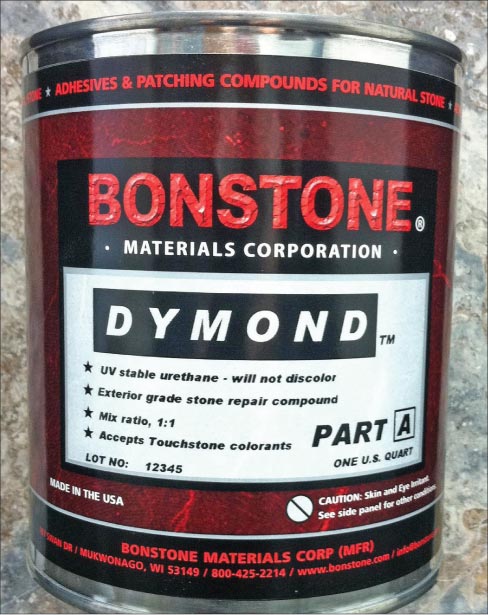

Here’s Dymond, in a very few words: “imagine Last Patch that gets harder, even faster”– that’s Dymond. It still has all those wonderful properties of Last Patch: colorless, easy to tint, easy 1:1 mix ratio, easy to apply, fast cure, excellent adhesion, great strength coupled with resiliency, non-yellowing, UV-stable . And now it also cures to a harder patch (allowing for easier polishing), and it cures much faster, too – More than twice as fast as Last Patch.

For instance, we have customers using Dymond to repair polished headstones, and they are “in-and-out” with a full color-matched and polished repair in under an hour.

We will continue to provide both the original Last Patch and the Dymond products. Though they are pretty much interchangeable, they each have their favored “sweet spots:” we mostly recommend Dymond for the harder stones (such as granite) where a high polish is required, or when someone is in a big hurry; and we recommend the original Last Patch for most other stones, or if you are working on a substrate that may experience some minor movement (such as an outdoor kitchen seam, since the slightly softer Last Patch has a little more “give” than the much-harder Dymond).

We suggest you give each of them a try in your application—you’ll most likely find one that meets YOUR sweet spot.

Last Patch and Dymond are made in the USA, and both are available through Braxton-Bragg, the premier Bonstone distributor in the U.S.

For more information call 800-575-4401 or visit their website www.braxton-bragg.com .

Starting with his B.S. in Chemistry in 1982, Mike Beckmann worked in developing epoxies and as National Epoxy Technical Service Representative for Reichhold Chemicals. In 1992, he arranged to purchase Bonstone, Inc. from then-owner and stone adhesive pioneer King Harte. The resultant company, now named Bonstone Materials Corporation, has since grown 8-fold in sales and number of employees. Mike continues to work full-time as President, and Chief Chemist, at Bonstone.