Classic Stone Works: High Country Experts in the Custom, Hand-Finished Approach

Joel Davis

Feature Contributor

Photos by Classic Stone Works

|

|

Classic Stone Works of Linville, North Carolina are pros in producing custom countertops. “We specialize in doing out-of-the ordinary countertops like curved islands and laminated, multi-profile edges,” said Production Manager Joe Magid. Above: Rainforest granite with a travertine tile backsplash and matching travertine farmhouse sink. |

|

|

Above: Onyx and absolute black inlaid floor makes a stunning entryway. |

|

|

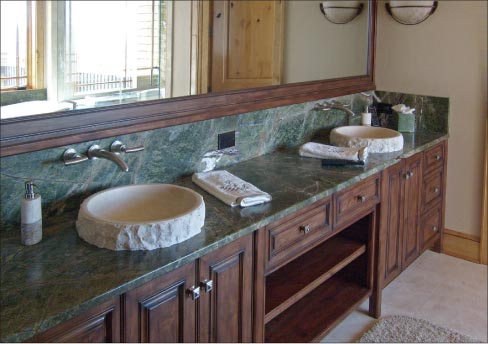

Above: Green rainforest double vanity top with hand-cut marble sinks. |

|

|

Above: This custom designed, fabricated, & installed Jerusalem Gold fireplace surround & hearth features clean, classic lines. |

|

|

Above: This custom bath features a Silver travertine vanity, backsplash and drop apron paired with an Absolute Black granite vessel sink. |

It starts with quality and taking the time to achieve it. “Our bottom line is not a number,” said Debbie Guinn, who owns the business with her husband, Eric. “It is how we did our job that counts. Our goal is for our clients to love their project once it is completed. We do not encourage fast turnaround. We want to do it right the first time.” Linville, North Carolina-based Classic Stone Works supplies quality stone countertops and custom stone projects from Key Largo to Manhattan. This is one stone company that isn’t tied down by its regional roots. So how does this small shop prosper in a high-end market?

High-quality custom work is the company’s specialty, Production Manager Joe Magid said. “We do a lot of high-end homes with high-end builders and designers. We specialize in doing out-of-the-ordinary countertops like curved islands and laminated multi-profile edges. It’s all custom work. We don’t do any cookie cutter or production-type multi-unit work.

The scale of a project doesn’t matter. Classic Stone Works can fulfill customer wishes. “Every job we do is a unique custom job,” Magid said. “We do anything from four-square foot vanities to 300-square-feet of countertops in houses.”

The company started out in the tile business. Now about 75 percent of jobs involve stone. “We do primarily natural stone, but we are getting more and more requests for quartz all the time,” Magid said. Engineered stone is growing in variety and popularity. “We are getting a lot more variety of materials from our distributors,” Magid said. “We’re getting some really pretty stuff that mimics natural stone,” Magid said. “It doesn’t all look uniform now. There are a lot of interesting patterns and great color choices. We’re able to help people who want the durability of granite but the look of marble. When that’s what they ask for, we steer them toward quartz.”

There is no typical Classic Stone Works project. “We have people from all over the country building vacation homes in this area. We have people who bring a lot of styles with them. There’s just not one specific style that is popular to the mountains because we get a wide diversity of clientele. We get a lot of different design requests. We still do a lot of mountain cabin looks, a lot of rustic treatments. We get requests for weathered materials and honed materials.”

Projects often reflect the mountain setting, though. “Our clients are steering more toward natural earthy looks as opposed to glitzy and flashy in their tile and countertops,” Magid said.

Classic Stone Works Inc. started in 1999 as Classic Tile and Marble. It began with only two employees. It was primarily a tile installation business. As business grew, it began getting requests for natural stone countertops. There were no fabrication shops in its service area. Its crews began traveling to Asheville to fulfill client needs.

After a few years, Eric and Debbie Guinn decided to expand. The company purchased fabrication equipment and moved to Banner Elk, N.C.

Then came the name change. The business relocated to Linville. “We’re in the middle of where everyone wants to be, the North Carolina mountain resorts,” said Debbie Guinn,

The business currently employs six fabricators. It has a total staff of about 15.

“Our employees are our family and we support each other on the job and away from the job,” Guinn said. “Every employee is dedicated to seeing Classic Stone Works be successful. Our success is their success, and we make sure they know it.”

Classic Stone Works has a full-service tile showroom and design center, but the business no longer installs tile, Magid said.

The company has a 15,000 square foot showroom and fabrication shop. It has the largest slab yard in the High Country of North Carolina.

“We buy from vendors up and down the East Coast,” Guinn said. “Most of our inventory is on consignment from different vendors. If a material does not sell then we switch it out for another.”

“We have done some nice work in the Diamond Creek development (in North Carolina),” Magid said. “For one of our higher-end builders, we’ve been doing some really interesting countertops with multi-profile laminated edges and curves and lots of mitered apron-front islands.”

Diamond Creek is a private gated golf course community. It is located outside of Banner Elk, and founded in 2003.

The company’s fabrication shop is heavy on manual equipment. “We have two Park Industries bridge saws that are manually operated,” Magid said. “We have a Park Industries Wizard Radial Arm Workstation.

Also, we’ve got our Marmo electric routers and lots of hand-tooling and air polishers.”

Manual tools suit the Classic Stone Works philosophy. “Primarily, everything we do is by hand,” Magid said. “We prefer the personal touch and having everything handmade as much as possible. We hand-build our own templates to use … that way we get the exact look we’re going for.”

The business has added a center pole crane to the shop. “We’ve been using that for the last few years, which has certainly made our production a lot quicker and safer for our fabricators,” Magid said.

Classic Stone Works focuses employee training. “All of our training is in-house,” Magid said. “We don’t have a high turnover so we’re able to train in-house and get people where they need to be as to the skills for their particular job.”

What sets Classic Stone Works apart from competitors is simple. “We offer a personal touch that our clients and contractors we work with really appreciate and keep coming back for,” Magid said. “We have a really high quality standard that we adhere to. All our return customers know to expect that regardless of what problems occur, they are going to end up with a high-quality product when the job is done. That is the thing we’re known best for – the overall quality of our work and dedication to making sure every job is as perfect as possible before we finish.”

This serves as the main advertising for the business. “It’s almost entirely world-of-mouth,” Magid said. “We do some very small local advertising. We don’t do any billboards or television or radio advertising.”

Referrals and repeat customers are the core of the business, Magid said. “We have designers… and even a lot of homeowners that have multiple projects going on that we see over and over again. Almost all of our business comes from our repeat customers and their referrals.”

Braxton-Bragg is Classic Stone Works’ primary supplier for fabrication tools and polishing pads, Magid said.

“We like the Viper line of pads,” Magid said. “We’ve tried lots of different pads, but we seem to get a better quality and faster polish with our Viper wet pads than anything else we’ve tried. We pretty much enjoy the entire Viper line.”

This includes wet pads, cutting pads, and drill bits. “There’s certainly a lot of miscellaneous items we buy there regularly,” Magid said.

The business doesn’t stand still. The staff continues to learn. The owners of Classic Stone Work are certified concrete countertop artisans. The business is working toward OSHA certification, Magid said. “That’s an important step for us.”

What’s next for Classic Stone Works? “We see a bright future,” Guinn said. “We plan on doing what makes us who we are —serving our clients to the best of our ability, turning out quality work that we stand behind, and having a good time while we do it.”

To learn more about Classic Stone Works, visit their website www.classicstoneworksinc.com