New Adhesive for Difficult White Marbles

Mike Beckmann

Special Contributor

We are all familiar with the typical adhesives that have been used in stone countertop fabrication for decades: polyesters, epoxies, acrylics, urethanes, and combinations we’ll simply call “hybrids.” In the spirit of “if it ain’t broke, don’t fix it,” those adhesives have served the industry well for many years. Until something new came along…

We are all familiar with the typical adhesives that have been used in stone countertop fabrication for decades: polyesters, epoxies, acrylics, urethanes, and combinations we’ll simply call “hybrids.” In the spirit of “if it ain’t broke, don’t fix it,” those adhesives have served the industry well for many years. Until something new came along…

With the recent skyrocketing popularity of ultra-white marbles like Carrara and Thassos, it’s become painfully evident that those chemistries mentioned above just don’t “cut it” on these materials. Sure, they stick just fine, but they cause what is variably called “shadowing,” “darkening,” “staining,” or “yellowing,” of the bond line — whatever you call it, it just looks bad.

It usually appears as a faint but definitely visible line along both sides of the joint. This line is caused predominantly by the “wetting” of the substrate by the adhesive. Think of water applied to dry, un-treated concrete — the light-colored concrete is immediately darkened as the water penetrates and fills the open pores of the concrete. This is not really “staining” in the classic sense, because when the water evaporates the concrete returns to its original color. With an adhesive, however, there is no evaporation so the darkening effect is permanent.

You might ask, “Why doesn’t this also happen with other marbles, or with granite, limestone, sandstone, etc?” That’s a very good question! And the answer is: no one has really been able to fully explain it (at least, to my satisfaction).

What is commonly postulated: 1. These marbles are more porous than the other stones, so the adhesives penetrate deeper; and 2. The ultra-white color of these stones exacerbates the darkening effect—it simply stands out more on a bright white than it would on a grey, red, or brown stone.

This makes sense to me… but regardless of the explanation—these adhesives don’t work!

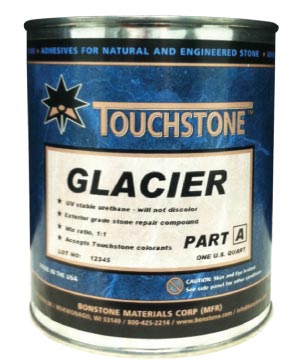

Bonstone Materials, Inc. has developed a solution to this problem. We have essentially modified an existing technology to create a new class of chemistry, so new it hasn’t even really been given an accepted name yet. For purposes of our discussion, let’s just call it “MPH”—stands for Modified Polyurethane Hybrid. Our trade name for this new product is Touchstone Glacier.

Touchstone Glacier is a 2-part adhesive, looking and acting very similarly to a conventional epoxy—with several critical differences. First, this new adhesive is ultra-clear—much better than even the clearest epoxy. Second, it doesn’t appear to have the affinity for the stone that the other adhesives have—it just doesn’t seem to “wick in” as much as the others (or perhaps because it’s so clear we just can’t see that it has). Finally, and probably most importantly—it cures so quickly that it doesn’t have time to soak in deeply.

Even though it doesn’t appear to penetrate deeply, it still has outstanding adhesive strength and durability – rivaling that of a high quality epoxy. And one more thing that really puts Touchstone Glacier in the winner’s circle – it is UV-stable and non-yellowing – making it ideal for outdoor installations!

Now for the first time, you can fabricate these popular marbles with confidence, knowing you have a permanent and invisible bond. And of course Touchstone Glacier also works on other stones too: marble, limestone, granite, travertine, onyx—it works on all these, and more—even engineered stones! And now Touchstone Glacier is also available in convenient cartridge packaging that fits a standard caulk gun—no special 2-component gun required.

Give Glacier a try. You’ll be glad you did.

Glacier is available through Braxton-Bragg, the premier Bonstone distributor in the U.S.

For more information call 800-575-4401 or visit their website www.braxton-bragg.com.