How to Build a Granite Business with $1,000 Bucks and Hard Work

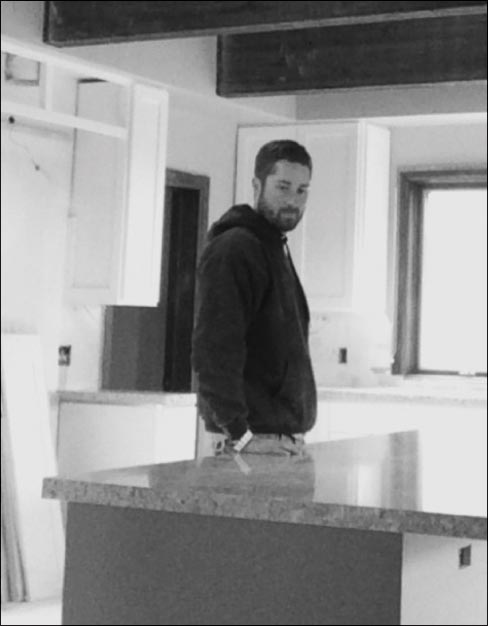

Shahn Ellis of Salt Lake City started up a granite business in 2010 with about $1,000 and a drive to succeed. Now, Ellis Stone is on its way to success in its niche market.

by Joel Davis

He started his business with $1,000 and a will to work hard. Five years later, Shahn Ellis is riding high. Although it hasn’t been easy, he says.

He started his business with $1,000 and a will to work hard. Five years later, Shahn Ellis is riding high. Although it hasn’t been easy, he says.

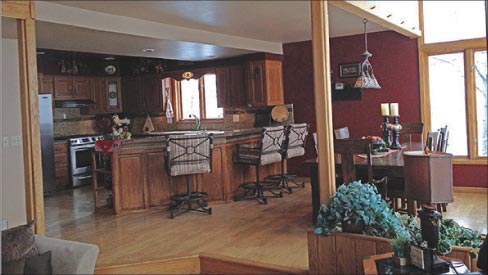

His company Ellis Stone is in Salt Lake City. It does much of its business in a nearby resort town. There are a lot of luxury properties, new construction and remodeling in the area.

His company Ellis Stone is in Salt Lake City. It does much of its business in a nearby resort town. There are a lot of luxury properties, new construction and remodeling in the area.

“We do higher-end, luxury-type kitchens, bathrooms, fireplaces, and surrounds,” Ellis said. “There are all kinds of different stuff that people want us to do. Not just your run-of-the-mill, one slab type, one color, in-and-out type of kitchens.”

“We do higher-end, luxury-type kitchens, bathrooms, fireplaces, and surrounds,” Ellis said. “There are all kinds of different stuff that people want us to do. Not just your run-of-the-mill, one slab type, one color, in-and-out type of kitchens.”

Building the business has been a challenge, but Ellis responded with a focus on customer care. “The secret is taking care of people and providing a good experience and just doing the best work you can possibly do,” he said. “If you can give them something they are proud of and want to invite friends and family over to look at, something to talk about, they are going to naturally refer you.”

Craftsmanship sets Ellis Stone apart. “Our signature is in the small details most overlook or simply do not do,” Ellis said. “It’s the little things multiplied that create a great client experience and a better finished product.”

Craftsmanship sets Ellis Stone apart. “Our signature is in the small details most overlook or simply do not do,” Ellis said. “It’s the little things multiplied that create a great client experience and a better finished product.”

The Ellis Stone fab shop relies on tools including a Park Industries Cougar Bridge Saw and a Single Speed Router.

The average Ellis Stone project is 80-120 square feet, mostly high-end residential. Quartz and miter edges are very popular. The average turnaround is 7-10 days. The shop did around 600 units last year. The company also installs cut-to-size multifamily projects.

The average Ellis Stone project is 80-120 square feet, mostly high-end residential. Quartz and miter edges are very popular. The average turnaround is 7-10 days. The shop did around 600 units last year. The company also installs cut-to-size multifamily projects.

Ellis gets his stone from several sources. The latest material gaining in popularity in his market is engineered stone. “We purchase our slabs from local suppliers where we have long standing relationships,” Ellis said. “We import our cut-to-size projects.

Ellis gets his stone from several sources. The latest material gaining in popularity in his market is engineered stone. “We purchase our slabs from local suppliers where we have long standing relationships,” Ellis said. “We import our cut-to-size projects.

“We will be starting to import and inventory slabs in the near future.”

Ellis has been a customer of Braxton-Bragg for more than five years. “I’ve been buying from Braxton-Bragg since the beginning,” he said. “They were one of my initial go-to suppliers.” (See page 38 for Shahn’s favorite products from Braxton-Bragg).

For environmental safety, the company also uses Novatek Nova air filters and an Abaco Dehydrator system, both also from Braxton-Bragg. The Abaco is an economical, one-step method for recycling water. It separates water from fabrication-produced sludge and slurry. “We strive to do as much as possible wet,” Ellis said.

Ellis Stone is OSHA certified. It is also a member of the Marble Institute of America.

Ellis plans to increase production through investing in equipment. “The next step for us will be a Saw Jet and digital templating equipment,” he said. “I believe equipment should not only increase production but enhance the artisan’s ability to create amazing works with stone.”

Eight years ago, Ellis got into the stone industry. “I’ve always loved working with my hands, and I had gotten a desk job and was going insane and got an opportunity to work in the countertop industry.”

Teaming up with a fabricator, Ellis went to work. A few years later, he started his own business. “I made the leap. I scraped together about $1,000 and just put together the most basic necessities to make it happen.”

The bare necessities meant a humble beginning. “I didn’t have a truck or shop or anything like that. I had a relationship with a contractor who had a bunch of spec houses he was trying to get done. He had a cargo van, and I did trade work for it. We just did everything 100 percent by hand on-site.”

Time passed. Ellis continued improving capacity. “I did that for a few months and had kind of gotten things together enough where I had gotten into a really small shop,” he said. “We were sill working mainly by hand. About two years into it, I found another shop that had just updated their bridge saw, so I bought their old bridge saw and moved into a bigger shop.”

Acquiring the saw proved a big step forward. “That bridge saw definitely helped things speed along, and it gave me capacity to increase production,” Ellis said. “I ran that pretty hard and heavy and I built it to where we were doing 7 to 10 kitchens a week, and I had seven employees.”

The growth did not bring happiness, though. “It just kind of got to be a grind for me,” he said. “I enjoy being involved in the hands-on part of it, doing fabrication and installation, so it just got to the point where I realized it was time for me to shrink things down and really focus on the niche of the jobs I liked working on – the more creative, higher-end type of projects.”

Ellis reduced his workforce to three employees and still completes three to four jobs per week. This depends on the size of the project. “I am a lot more hands-on and involved in the whole process,” he said. “It’s been a whole lot more enjoyable than the chaos and thinking I had to get every single job I was bidding on.”

Ellis reduced his workforce to three employees and still completes three to four jobs per week. This depends on the size of the project. “I am a lot more hands-on and involved in the whole process,” he said. “It’s been a whole lot more enjoyable than the chaos and thinking I had to get every single job I was bidding on.”

Focusing on less but higher quality jobs improved revenue. “It’s been half the headache,” he said. “At the end of the day, I’m taking home about double the money.”

Times have improved. Ellis has a new goal. “I’m starting to provide some information and mentoring for other people to help them avoid some of the things that I’ve gone through and try to change the mindset. Many people get into the industry and think we’ve got to grow to this huge company. It drives the whole industry into who can be the lowest bid and who can do the most volume, and it takes away from all the people who are really artisans and have those skills.”

Having tools is good. Knowing how to use them is even better. “I have nothing against technology,” Ellis said. “I just feel it should enhance the skills of a craftsman and not replace him. If you know what you’re doing, you don’t have to be in a race to the bottom to see who can be the cheapest. There are people out there who want quality, and you can have a very sustainable and very profitable business without being a massive company and relying on volume to make ends meet.”

An important business breakthrough for Ellis involved appropriate pricing. He found the lowest price wasn’t always the best. “I’ve come to the realization that when I value me and am comfortable charging what I know that I’m worth, then my clients value me and they value my work more,” he said. “Trust that people will pay for the quality they want.”

Newcomers to the industry need to know this, Ellis said. “The best piece of advice I could give them is don’t try to be the lowest bid. I did it, too. I did a ton of work and was crazy busy and had a ton of stress, but at the end of the day you can be really busy and not make any money.”

When you do most of your fabrication work by hand, the tools and supplies you choose become even more important in making your work profitable. Buying dependable tools and supplies at a great price has helped Shahn Ellis succeed. He relies on tools and supplies from Braxton-Bragg. Some of his favorites are:

When you do most of your fabrication work by hand, the tools and supplies you choose become even more important in making your work profitable. Buying dependable tools and supplies at a great price has helped Shahn Ellis succeed. He relies on tools and supplies from Braxton-Bragg. Some of his favorites are:

Viper 3-Step Polishing Pads

Viper 3-Step Polishing Pads

“We love these pads for polishing backsplashes and onsite polishing during installation. They are the only 3 step pads that actually work. I have tried them all.”

EZ-Dishwasher Bracket

“This product is the safest, quickest and easiest way to mount a dishwasher– hands down.”

U-Mount Undermount Sink Supports

U-Mount Undermount Sink Supports

“There is nothing worse than getting a call from an angry client whose sink was full of water and dishes, and just fell into the sink cabinet. U-Mounts make sure it never happens again.”

TemplatePro Templating Kit

“I like that I can use a compact car to go out and do a template on a jobsite because the finished templates can be rolled up without worry.”

Viper Dry Diamond Core Drill Bits Side Protection

“These are the fastest, longest lasting dry core bits I have found.”

Hercules Grinder Gear & Makita 9565CV Grinder

“Cut the dust and stop burning up angle grinders. We transitioned to a wet fabrication process and these grinder covers have been invaluable. They have cut my Makita (9565CV) angle grinder consumption by over half.”

Hercules Variable Speed Wet Air Polisher

“I use an air tool almost daily for polishing. The Hercules is reliable and easy to use.”

Stone Pro Suction Vacuum Cup Assembly System

“There is nothing worse than spending hours fabricating a kitchen to perfection and breaking a sink run. It takes less than 1 minute to put the sink savers on so you never break a piece again.”

Abaco Self-Locking Slab Trolley

“My trolley is a back saver and it’s great for rough terrain. It also holds big pieces up off the ground so they are easier to lift onto the cabinet during installation.”

For more information on the tools mentioned here visit www.braxton-bragg.com.