Restoration and Maintenance Corner- My Life in the Stone Industry

Bob Murrell

Stone Restoration

Photos Courtesy Bob Murrell and Thompson Professional Photographer Archives

I am taking a break from the technical issues this month with a little history of my growing up in the stone industry. Hopefully it may help you understand where I got my experience in and why I believe what I do about certain technical issues.

So, here is a quick story on my background. I was a wayward child in my late teens, twenties, and early thirties. Some thought I would never grow up, including myself. Fortunately for me, I met my wonderful wife around the age of 35 and have been on the road to adulthood ever since (over 20 years now, and counting). Now that we have two beautiful daughters, I realize that life is coming back full circle to bite me. At least I know what boys to look out for!

So, here is a quick story on my background. I was a wayward child in my late teens, twenties, and early thirties. Some thought I would never grow up, including myself. Fortunately for me, I met my wonderful wife around the age of 35 and have been on the road to adulthood ever since (over 20 years now, and counting). Now that we have two beautiful daughters, I realize that life is coming back full circle to bite me. At least I know what boys to look out for!

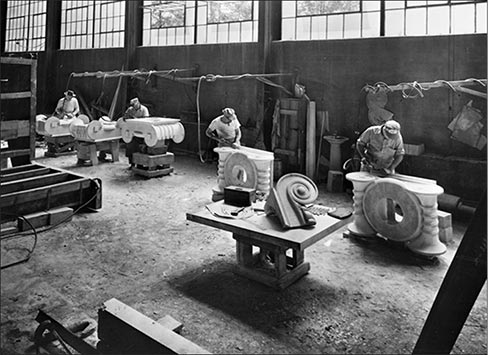

My grandfather on my step-dad’s side worked at Candoro Marble Company in Knoxville, TN starting in the 1940s. Candoro Marble Company along with Vermont Marble, Indiana Limestone and Georgia Marble were some of the longest operating quarries and mills in the country.

My grandfather on my step-dad’s side worked at Candoro Marble Company in Knoxville, TN starting in the 1940s. Candoro Marble Company along with Vermont Marble, Indiana Limestone and Georgia Marble were some of the longest operating quarries and mills in the country.

I used to love to go there when I was a kid. It was gigantic! My dad would take me during summer break from school and it was the neatest place. Large block saws were run from one giant overhead shaft. Copious amounts of water and sand were pumped into the large reciprocating saw blades.

Best I remember, it took days to cut up the blocks of Pink Tennessee marble, which now take only hours with modern diamond saws. A large part of the marble in Washington DC came from Candoro Marble Company. Many Government buildings as well as The Smithsonian and National Museum of American History are perfect examples of the beautiful stone that came out of Candoro.

Grandpa was a book matcher and polisher. He matched cut slabs together so that the veins and patterns lined up perfectly in a mirror image. Book matching was an art as was polishing the material itself, at that time.

He was called in anytime they had a material that was difficult to take a good polish. In search of a solution for difficult–to-polishing materials, he started Greenstone, a company that developed special honing and polishing abrasives called Greenstone Hones.

They became very popular with many marble quarries and fabricators and were referred to commonly as “bricks.” We also made corn shuck buffing heads which were used with putty powder (aluminum oxide and oxalic acid) to create one of the best polishing systems available at the time.

I would work on the weekends for .75¢ per hour (I was 10 years old in 1968) making these bricks with my dad and Grandpa. It was hot, miserable work. Sawdust had to be cut from oak boards, one saw blade width at a time– talk about boring. Not to mention that Carcinogenic resins (no one knew, at the time) were also used, along with aluminum oxides, silicon carbides, and Methyl-Ethel-Ketone (MEK) for hardener.

All bad stuff for 10-year-olds but like any American kid, I wanted stuff, so work was a necessary evil. To beat it all, we had determined that it had to be about 110 degrees minimum for the hones to set up properly. Whew…

After years of supplying the Greenstone Hones to other marble companies, these same companies began to ask my dad for other products, too. When industrial diamonds started revolutionizing the stone industry, he started supplying many different products and started VICCO in about 1975.

I continued to earn money making bricks on the weekends through high school. The company grew and grew and became one of the leading suppliers in the American stone industry. After graduating high school, I left Knoxville to join the Navy in 1978.

During this time, my dad continued to grow the business and the name changed to Vic Industrial Corporation. I left the Navy after a 4-year hitch in 1982, then attended college and once again began working to augment my monetary needs through– guess what– making hones and shuck heads. By now, there was a shipping department, inventory, and administrative office. I did what I knew how to do and others didn’t want to do.

After graduating college and then working at a nuclear power plant for a few years, I decided to come home and work with my dad again. Granny always said I had the gift of gab so it was decided that I would try sales. It was a perfect fit and I have never looked back.

By this time the company was called VIC International. We decided that all of this stone that was installed needed a comprehensive maintenance program to keep it looking new. At the time, there were only a few companies that had some sealers and a handful of other items, so we started the Restoration & Maintenance (R&M) division.

It was a huge success. We grew the division to be the largest supplier of restoration and maintenance products in the U.S.A. We developed many of our own products, brought in premium products from Germany and Italy (where I have visited many times), and then marketed it all through national distribution.

By developing the most successful training center in North America, we trained thousands of contractors from around the world. Chances are, if you have attended a training seminar, it was based on the VIC International training school format. We built the largest Stone Care distribution in the world, over 80 distributors in 7 countries.

After designing and adding our own line, Stone Medic, to the existing line of products, we had the most complete system anywhere. It was so successful, we ended up selling the division to one of the largest Jan-San supply companies in the world in 2002.

Through the years, I also did my share of actual restoration work both locally and across the country. I have restored thousands and thousands of square feet of most all types of stone, terrazzo, and concrete. I bought my extra amenities (boats, cars and motorcycles) with this side job money. I just never took the plunge to do it full-time as dad said he needed me at the company.

I stayed behind while the rest of the division went with the R&M sale and was moved to head up the Equipment Sales Division. In 2003 we started selling CNC machines, saws, and edge machines faster than we could bring them in from Italy.

Once again, life was good. The construction industry was booming. Unfortunately, sometimes good things do not last and with the economic crash of 2008, so did the equipment sales business. Machine sales dropped by at least 80% as did the most of the construction industry. Repossessed, below-cost equipment flooded the market.

The up-side was that our non-compete with the R&M sale was almost up, so we started designing our new product line. After all, we were once the biggest in the industry. This new program started growing quickly but the construction supply crash had already taken a drastic toll on the company.

VIC International closed their doors in March of 2012 after over 35 years of industry-leading innovation and sales. It was a devastating blow to everyone who worked there as well as the many customers who had grown to depend on us.

I was very blessed to have acquired the skills of the trade over most of my life and found employment with a good company called M3 Technologies within a month of being out of work. I have been working with M3 Technologies going on three years now and I still love doing what I do best. Of course, that is selling quality products and giving the best technical support I can to the stone industry, now going on well over 35 years.

This great industry has allowed me to travel the world, see some of the most beautiful structures built by man, help restore many upscale and historic installations, all while meeting many interesting and knowledgeable people associated with the trade. I am very thankful for that.

What I have learned is that life can be both kind and cruel. You have to do the best that you can to help make a positive difference in the world. Like many people, I wish I could take back the many years I squandered. But then, with such a great opportunity for the rest of my life, I have to wonder if it was all just part of my growing up experience.

Bob Murrell has worked as a supplier of products and technical support to the natural stone industry for over 35 years. He has written numerous articles for various trade publications and has also trained thousands of contractors over the last 25 years.