Keith’s Quality Marble and Granite

Proving Quality Belongs in Their Name

by Joel Davis

Photos Courtesy Arica Olson and Keith’s Quality Marble & Granite

Keith's Quality Marble and Granite Inc. of Holly Hill, Florida, is proving that even in today’s hyper-competitive stone marketplace, doing things the right way is never old-fashioned.

Keith's Quality Marble and Granite Inc. of Holly Hill, Florida, is proving that even in today’s hyper-competitive stone marketplace, doing things the right way is never old-fashioned.

The company provides luxury kitchen and bathroom remodeling service. Business really took off after Keith’s began fabricating its own stone countertops about three years ago.

The company provides luxury kitchen and bathroom remodeling service. Business really took off after Keith’s began fabricating its own stone countertops about three years ago.

Keith Edwards co-owns the business with his son, Jonathan. He has been in the tile and marble business for 39 years.

“We’ve grown from three people to 23 people at this point,” Edwards said. “We’ve been doing quite a bit of business. We average from three to four kitchens a day.”

Once Keith’s began making its own countertops, customers started pouring in. “The second year business doubled, and this year we’ve almost doubled again, which is almost unreal,” Edwards said. “We’re doing something that is obviously right. We want to continue to do that.

“It has a lot to do with the guys in the shop. They’ll keep us going. If this economy keeps rolling, we’re going to roll right with it. My son says we’re riding a train. That’s what we’re going to do.”

In November, Keith’s moved into its current 21,000 square foot facility, which is a far cry from the 1,300 square-foot garage it had been operating out of a few years before. “We have really grown,” Edwards said. “It’s been beneficial for us. It gives us a venue to display some of our goods.”

Edwards believes in having strong personal investment in the craftsmen that work for him. “An important factor for me is my relationship to my help,” he said. “These are good boys, they have good families and whatever help we can give them we do. We try to keep close to them.”

The fab shop crew at Keith’s is extremely talented, Edwards said. “In my opinion, we have some of the finest fabricators. One of our boys can literally turbo a top almost dry. We call him our little Master Yoda in the shop. He just does a heck of a job. He can build sinks out of granite by hand.”

In addition to a 6,000 square-foot fabrication shop, the Keith’s facilities include a 1,200 square-foot template shop. “Everything we do is old-school,” Edwards said. “It isn’t digital. We do everything by hand, which we pride ourselves in.”

The company has invested in new technology to complement its emphasis on manual craftsmanship — finding tools to improve the product while retaining the hands-on approach.

“We just bought a machine for dropping sinks,” he said. “It’s called the Fab King. We love it to death. It saves us a lot of time.”

“We just bought a machine for dropping sinks,” he said. “It’s called the Fab King. We love it to death. It saves us a lot of time.”

The Fab King Work Center, manufactured by RYE-Corp and distributed through Braxton-Bragg, can be used to cut out sinks, profile edges, drill utility holes, polish back splashes, antique stone, and polish out scratches.

The Fab King Work Center, manufactured by RYE-Corp and distributed through Braxton-Bragg, can be used to cut out sinks, profile edges, drill utility holes, polish back splashes, antique stone, and polish out scratches.

“Machinery is a wonderful thing,” Edwards said. “We’ve done everything stone age for quite a while, and we’re growing.”

“Machinery is a wonderful thing,” Edwards said. “We’ve done everything stone age for quite a while, and we’re growing.”

In addition to the Fab King, the Keith’s shop includes a Marmol line machine and an automated bridge saw.

In addition to the Fab King, the Keith’s shop includes a Marmol line machine and an automated bridge saw.

Taking care of the crew pays off with reduced turnover in the staff, Edwards said. “We have a very good continuity within the shop, which I love. You don’t see that often. It takes a little bit of work to get to that point, but it’s something we strive for.”

Taking care of the crew pays off with reduced turnover in the staff, Edwards said. “We have a very good continuity within the shop, which I love. You don’t see that often. It takes a little bit of work to get to that point, but it’s something we strive for.”

Keith’s recent growth has come despite the continuing effects of the economic downturn of recent years.

Keith’s recent growth has come despite the continuing effects of the economic downturn of recent years.

“For the last three years what we do has really been a good thing in the area we’re in,” Edwards said. “We have come out of a hard economy. This business environment has just been hard, but we built our business in hard times, and, by doing so, we got our foot in the door on hopefully what we’d call a turnaround.”

One of the most important components of Keith’s recent success has been based on good management, Edwards said. “I have an office manager who is a heck of a bulldog. Billy Simpson is probably one of the best I’ve ever seen.

“He’s helped to structure and build our business to where it is today. He is very aggressive. He is good with operating the sales end of this thing.”

Edwards began his career in 1975 as an apprentice at a tile and stone business. After about five years, he went into business for himself. Enjoying marble work and design, he gravitated toward technically complex projects, difficult designs that were too high-tech or architecturally challenging for most shops to be interested in taking on. “I could take two to three months in a bathroom doing a mosaic, and it wouldn’t bother me at all,” he said.

It was during these years that Edwards developed his insistence on quality and craftsmanship. “I did what the customer wanted,” he said. “I made sure it was right. I was always the guy more concerned with what was going on behind the tile or marble more than finish because I knew if you got that right, it would be perfect.”

Edwards calls Keith’s a family-oriented business. In addition to his son, the business also employs a cousin, his youngest daughter and son-in-law, a sister-in-law, and even his 81-year-old father, whose duties range from transporting materials to cutting the grass at the shop. “He’s having a blast,” Edwards said. “It is definitely a family-run business, and we’re proud of that.”

When Keith’s began installing countertops, Edwards soon found that he could not rely on the craftsmanship of third party fabricators to meet his standards or needs. Not always satisfied with the products available to it, Keith’s expanded into fabrication services itself in 2011. This turned out to be a tremendous asset for the company.

“I couldn’t control my quality, and I couldn’t control pricing,” Edwards said. “That was an issue for us, so we decided to do it for ourselves. Now we have our own control over our quality, which is a very big factor for me and my company.”

Being able to have direct control over the quality of the products is very important to Edwards, who values being able to deliver exactly what the customers want.

“If I tell you we’re going to be there, we’re going to be there,” he said. “I’m a man of my word and the guys in my shop know that. What we say is what we mean, and we stand up behind it.”

The company’s business philosophy is simple. Customers are the first priority at Keith’s Quality Marble and Granite. Satisfaction with the service is guaranteed and the crews work hard and pay attention to every detail for its clients’ home projects.

In an industry dominated by competition driven by slender margins, Keith’s Quality Marble and Granite refuses to take shortcuts that save money but inconvenience the customers. “We make sure our customer service is number one,” Edwards said. “This is a must. It’s very hard to do that in the granite business.

Continued from page 2

We are going to answer the phone, show up, and do what we need to do to make the job what it needs to be.”

Edwards said he tries to instill those values in his fabricators. “I want to make sure the customers are comfortable with us. It’s not just another job for me. We get to know them as much as we possibly can. We help everywhere we can.”

Whether his crews are installing a cookie cutter prefab sink or working on a high-end luxury custom job, Edwards preaches consistency. “We do the same quality of work on both. It’s a pure fact for us. I address that stone top and bottom. I want my overhang to be smooth. That’s a big thing to me. Whether it’s a standard top or a custom top, we address it the same. We are trying to keep the quality where it needs to be. I think the industry has lost that because of the competition.”

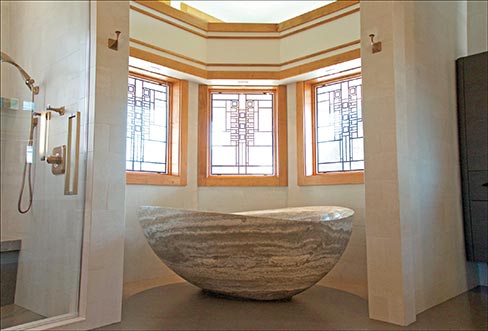

Keith’s recently finished a project on a Frank Lloyd Wright-inspired house for a customer. It took two years and eight months of effort, involving what Edwards called “over-the-top, extremely perfect work” on more than 2,000 square-feet of stone inside and more than 4,000 square-feet, outside.

“I’ve been privileged to be on quite a few jobs like that,” he said. “They are very artistic, and they don’t go fast. A job like that is not done by the foot. Not too many people get to do that.”

As the price and quality of available stone has changed over the years, fab shops have had to compete aggressively on price but cutting corners is not the way that Keith’s does business, Edwards said. “Now we have to be competitive, but our competitive edge is not just the price, it’s the quality and the service. Those are the adages that help us make our business successful. We’re proud of that.”

As a family business, Keith’s has benefited from the vision of Edward’s son, Jonathan, he said. “When we get older, we don’t dream like we do when we’re young. I dreamed when I was young.”

This collaboration pushes the company forward. “We meet, we talk, and we make discoveries,” Edwards said. “We are by no means done. We have more plans ahead of us.”

For more information visit their website www.keithsqualitymarbleandgranite.com