2013 MIA Pinnacle Awards, Part 2 of 2

The Marble Institute of America announced the winners of the 2013 Pinnacle Awards competition during its annual Awards Luncheon held during StonExpo/Marmomacc Americas 2014.

The Marble Institute of America announced the winners of the 2013 Pinnacle Awards competition during its annual Awards Luncheon held during StonExpo/Marmomacc Americas 2014.

The Pinnacle Awards recognize excellence in commercial, residential, and renovation/restoration of natural stone projects worldwide. Projects selected as winners must demonstrate exceptional beauty, creativity, ingenuity and craftsmanship in the use of granite, marble, travertine, limestone, and other natural stones. The sponsors of the Pinnacle Awards are Custom Building Products and Aqua Mix for the Pinnacle Commercial Awards, BLANCO for the Pinnacle Residential Awards and Coldspring for the Pinnacle Renovation/Restoration Awards. The competition is open to MIA members around the world.

During the Awards Luncheon, the MIA also presented the 6th annual Grande Pinnacle Award, sponsored by Marmomacc. A Grande Pinnacle Award was also presented to the architect involved with the winning project.

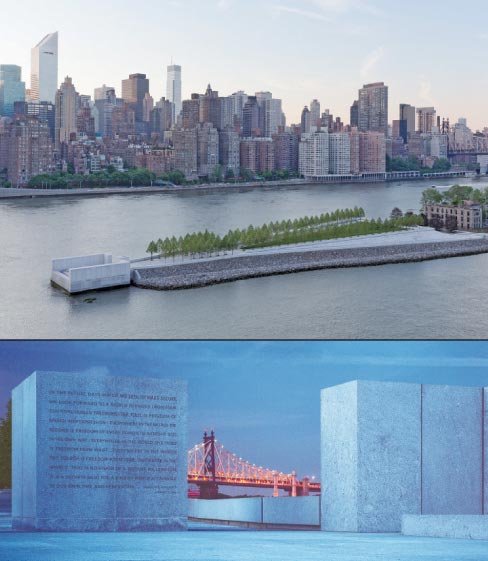

The 2013 Grande Pinnacle Award winner:

North Carolina Granite Corporation of Mount Airy, NC for the amazing Franklin D. Roosevelt Four Freedoms Park on Welfare Island, New York, NY.

In 1973, Welfare Island, a two-mile long strip of land in the center of the East River of New York City, was renamed for President Franklin D. Roosevelt, and the southernmost four acres were dedicated as a memorial for him. It was designed by the preeminent architect, Louis I. Kahn in the 1970’s. The “Room,” the southernmost part of the completed design, is the physical realization of Kahn’s famous quote: “The walls parted and the columns became,” his notion about a basic relationship between two indispensable architectural elements. The project evokes the eternal, a fitting memorial to Roosevelt’s legacy and his four Freedoms (speech, worship, want, fear). All granite that makes up Franklin D. Roosevelt Four Freedoms Park was quarried in Mount Airy, NC at the North Carolina Granite Corporation. 12,100 tons (roughly 24 million pounds) of granite were quarried to produce 7,700 tons (roughly 15 million pounds) of dimension granite. The solid granite blocks used to make the “Room” measure 6 by 6 by 12 ft. and weigh 36 tons.

The architectural firm of Mitchell/Giurgola Architects, Architect of Record for the project, was also presented with a Grande Pinnacle Award.

The 2013 Pinnacle Award winners are:

- Commercial Exterior Award of Excellence to Coldspring, Cold Spring, MN for the Intuit, Inc. headquarters in Silicon Valley, CA.

- Commercial Exterior Award of Excellence to Coldspring, Cold Spring, MN for the Ralph L. Carr Colorado Judicial Center in Denver, CO.

- Residential Interior/Exterior Award of Excellence to Valders Stone & Marble, Inc., Valders, WI for a Long Island Residence in Long Island, NY.

- Residential Interior/Exterior Award of Excellence to M&G Contracts (S) PTE LTD, Singapore for the Ardmore Residence in Singapore.

- Renovation/Restoration Award of Excellence to Miller Druck Specialty Contracting, Inc., New York, NY for the 632 Broadway building in New York, NY.

- Renovation/Restoration Award of Excellence to Rugo Stone, LLC, Lorton, VA for the Cathedral of the Immaculate Conception in Wichita, KS.

The Pinnacle Awards of Excellence were all featured in the April issue of the Slippery Rock Gazette.

Congratulations to all the winners.

Judges for the 2013 Pinnacle Awards competition were:

- Kent Duffy FAIA, SRG Partnership in Portland, OR.

- Steve Poland, Ankrom Moisan Architects in Portland, OR.

- Christian Pongratz, Pongratz Perbellini Architects in Verona, Italy.

- Michael Twiss, Immediate MIA Past President, Columbia Stone, Inc. in Tualatin, OR.

- Chuck Muehlbauer, Technical Director, Marble Institute of America in Cleveland, OH.

Photo by Martin van Hemert

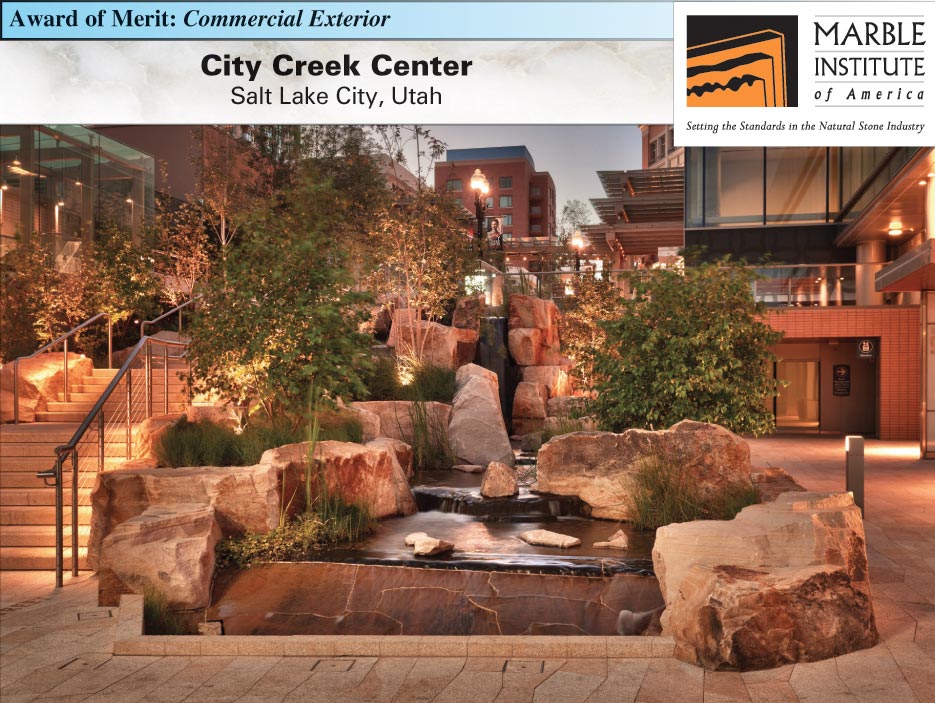

City Creek Center

Salt Lake City, Utah

MIA Member Company:

Bestview International

Glenview, Illinois

Stone Supplier | Stone Fabricator

Coldspring

Cold Spring, Minnesota

Stone Supplier | Stone Fabricator

KEPCO+

Salt Lake City, Utah

Stone Installer

Other Project Team Members:

City Creek Reserve Inc.

Client

SWA Group • WET Design

Hobbs & Black

CMS Collaborative Inc.

Architects

Jacobsen Construction

General Contractor

Caffall Tile & Stone Co., Inc.

(MIA Member Company)

Stone Installer

Delta Stone

Stone Supplier | Stone Fabricator

Stones:

Prairie Brown Granite, Mesabi Black® Granite

Pepper Brown Granite

Mountain Valley Sandstone

Mountain Blend Sandstone, Sunset Gold Granite

Yellow Supreme Granite

Giallo Imperial Granite

Giallo Veneziano Granite, Black Rain Granite

Salt Lake City’s 23-acre City Creek Center is the perfect balance of modern innovation and natural beauty. A LEED Gold-certified project, City Creek Center is part of a revitalization plan to re-establish the city’s downtown as a vibrant economic and cultural center. One of the Center’s most impressive features is the amazingly accurate replica of City Creek, the project’s namesake. The realistic man-made creek flows through two city blocks and includes three waterfalls, with the tallest measuring 18 feet high. 3D models of each cascade were created to assist in the careful selection of the project’s 275 boulders. Boulders were quarried locally so that the stone would be natural to the area and consistent with the architect’s desired color range.

The City Creek Center also features seven unique natural stone fountains, with three offering interactive experiences. The “Flutter” and “Transcend” fountains capture the attention of patrons with their choreographed fire and water displays, while “Engage” invites children to interact with its energetic bursts of water. The project incorporates seven different granites and two types of sandstone totaling 15,400 cubic feet of natural stone. Coldspring fabricated the Mesabi Black® and Prairie Brown granites used for several of the fountains, including the pieces requiring perfectly positioned holes for water jets, light fixtures, and fire nozzles. Bestview International fabricated the Sunset Gold granite used in the project’s intricately designed 12-piece paving pattern, and Yellow Supreme, Giallo Veneziano, Giallo Imperial and Black Rain granites used in the project’s exterior cladding. Cladding contractor KEPCO+ installed the stonework for all of the water features and much of the paving. The success of this project would not have been possible without the collaborative efforts of the complete stone team. The City Creek Center is enjoyed by all and will share its beauty, innovation, and tranquility with both locals and visitors for generations to come.

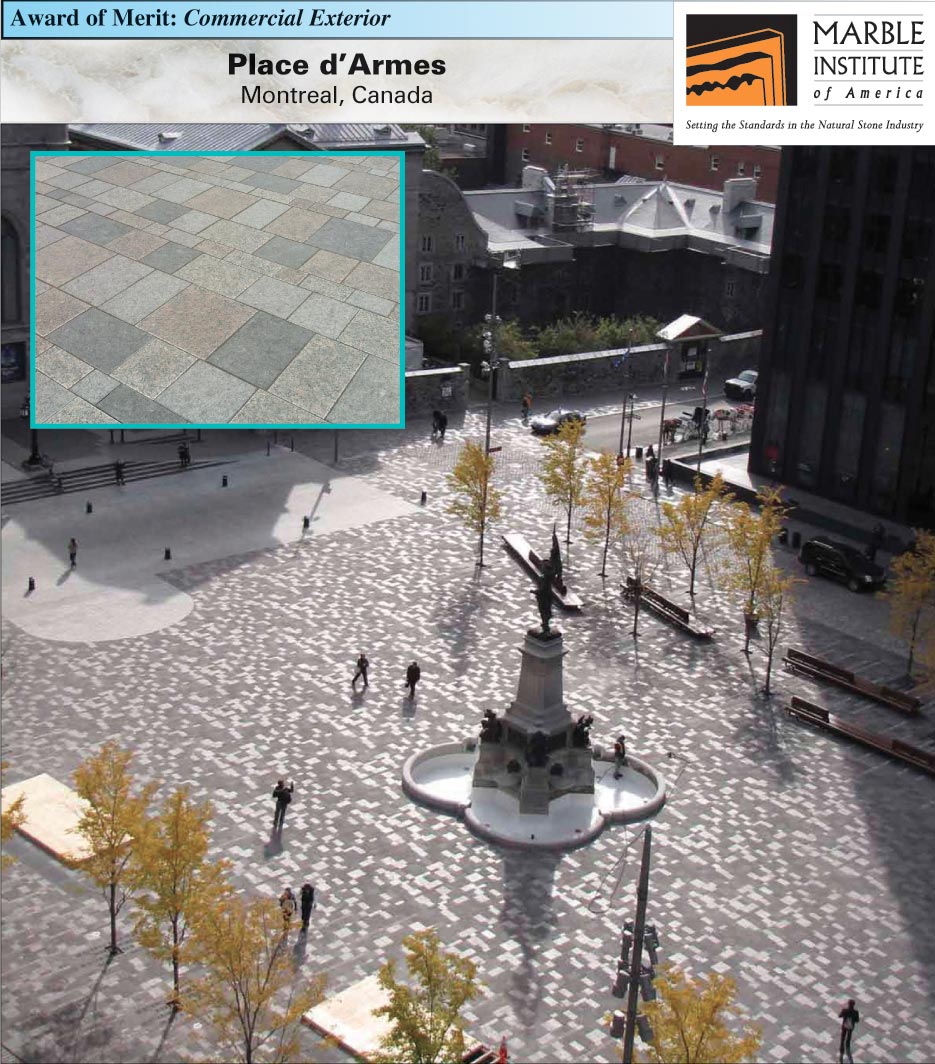

Place d’Armes

Place d’Armes

Montreal, Canada

MIA Member Company:

POLYCOR INC.

Quebec, Canada

Stone Supplier

Stone Fabricator

Other Project Team Members:

City of Montreal

Client

Cardinal Hardy

Architect

Terramex

General Contractor

Installer

Stones:

Caledonia Granite

Newton Brown Granite

Peribonka Granite

Stanstead Granite

The Place d’Armes project was not only to completely refurbish one of the most visited plazas in Montreal, but also to lower it to street level. The same running bond pattern paving was used for the plaza, crosswalks and streets requiring many different thicknesses, all with a 5mm bevel on top and bottom to avoid lippage.

The mix of color was not random, but an established pattern and every single piece had to be numbered and crated in sequence.

Additionally, to the color/finish/thickness mix, two other factors were complicating the fabrication. Because the two main streets on the North and South sides of the plaza are not perfectly parallel, a few bonds had to be fabricated with slight angles to adjust without it being noticeable.

Also, all the end pieces abutting the historical buildings had to be shop ticketed for a perfect fit without any field cutting. Aside from the logistical complexity, the multiple dimensions required in each color/finish/thickness allowed the recovery of waste to fabricate smaller pieces from the nonconforming larger ones. Cobblestones of the former plaza were also reused as accents.

Now complete, the new plaza is one of the nicest touristic, gathering places in Montreal, and will withstand even the harsh Montreal climate and the abuse of snow removal equipment.

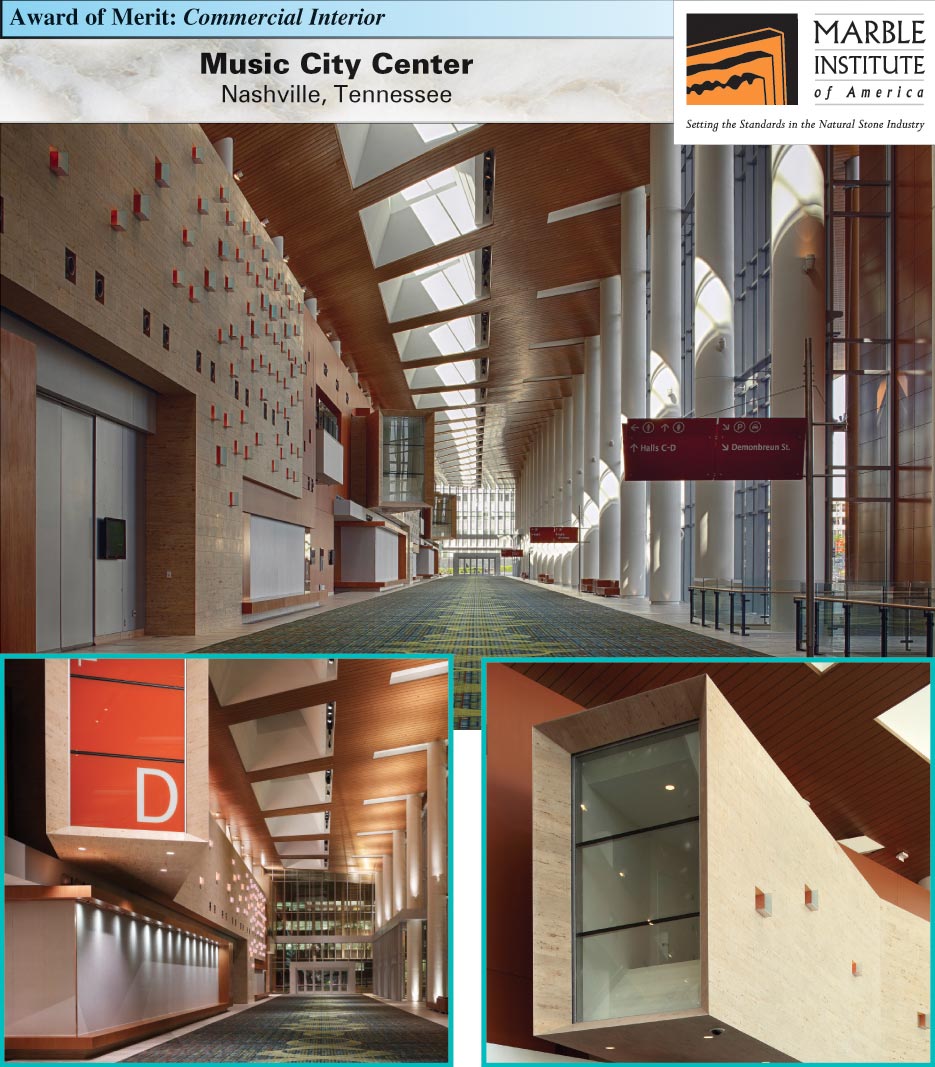

Music City Center

Nashville, Tennessee

MIA Member Company:

Associated Imports

Atlanta, Georgia

Stone Fabricator

Stone Installer

Other Project Team Members:

Convention Center Authority

Client

TVS Design

Tuck Hinton Architects

Moody-Nolan Architects

Architects

Simpson Construction Inc.

General Contractor

Bell/Clark a Joint Venture

Construction Manager

Jurassic Marble Suppliers

Stone Fabricator | Stone Supplier

Stones:

Jura Beige Limestone

Sahara Granite

Associated Imports was contracted as the prime contractor to supply, fabricate and install the natural stone building veneer at both the interior and exterior locations of the Music City Center. By collaborating with TVS Design early in the design phase, they were able to size the limestone panels at 15 inches tall, which maximized the block usage and minimized the waste, which in turn provided the best overall value to the project.

This particular quarry layer was 48 inches tall and, when processed into three 15 inches tall vein cut panels, it yielded three fairly distinctive panels; light vein, heavy vein and a no vein, or “mud” panel. Once properly blended onsite, the end project was seamless.

This early involvement allowed for optimal stone usage and coordination/alignment with other materials, such as window mullions, metal panels and brick coursing.

In addition to the 24,500 sq. ft. of exterior limestone veneer, 4,500 sq. ft. of cubic stone caps and 2,200 sq. ft. of exterior granite, the interior concourse hosted the most dramatic stone facades. The main concourse contained three large feature walls, each 125 ft. long and 35 ft. high. Each wall was accentuated with pocket lights trimmed in acrylic. This combination provided a great ambiance when viewed from both the interior and the exterior.

The project earned a LEED Silver certification. Sustainability features included a four-acre green roof and 260,000 gallon rain water retention tank. Associated Imports was able to contribute by providing local and recycled setting materials including thin set, grout and the stone joint sealants.

Associated Imports also directed 20% of the contract value to help meet the overall project’s goals for the DBE participation. As a whole, over 130 minority/women/disadvantaged businesses were contracted for the project.

Liberty Mutual Insurance Company World Headquarters

Boston, Massachusetts

MIA Member Company:

Kenneth Castellucci & Associates

Lincoln, Rhode Island

Stone Installer

Client

Liberty Mutual Insurance Company

Other Project Team Members:

CBT Architects

Architects

Turner Construction Company

Construction Manager

Polycor (MIA member)

Euromarble

Granites of America

Stone Suppliers

Stones:

Roman Travertine

Cambrian Black Granite

Jet Mist Granite

The project encompasses the expansion of the Liberty Mutual Insurance Company world headquarters within an urban corporate campus in Boston, MA. The new twenty-two-story office building lobby is an elegant two-story space connected by a grand staircase of stone and glass.

The first floor lobby welcomes employees and visitors into the building. The second floor lobby connects to a pedestrian bridge and corporate cafeteria. The lobby walls are comprised of a series of articulated travertine panels accented by floor to ceiling light coves that highlight the articulation. Dark cherry wood panels complement the 10,000 sq. ft. of Roman travertine. The floors consist of two types of North American granite: Jet Mist and Cambrian Black featuring thermal finishes.

The most challenging aspect of the interior installation was the use of Roman travertine. The design plan called for a completely uniform background color with individual stones placed randomly to avoid a repetitive pattern.

This was achieved by having the project team make six trips to Italy. The initial trip entailed reviewing the slabs to establish the allowable range of material and size of the allowable fissures.

Subsequent trips included visiting the quarry to hand select the seven blocks required for the project and a trip to the fabrication facility to review the slabs from the selected blocks to ensure that they met the design intent and the allowable range approved during the initial trip. Another visit to the fabrication facility to review the entire 10,000 sq. ft. dry-laid elevation by elevation allowed the architect to reject any stones that did not meet the approved range.

In addition, the architect was able to place individual pieces to achieve the desired “random” look. After each dry-lay was completed, each stone was assigned an individual number to determine its final installation location in the lobby.

Renaissance Shanghai Putuo Hotel

Renaissance Shanghai Putuo Hotel

Shanghai, P.R.C.

MIA Member Company:

Creative Edge Master Shop, Inc.

Fairfield, Iowa

Floor Design and Fabrication

Other Project Team Members:

MingJie Real Estate

Client

VOA Architects

Interior Designer

Aalto Design

FNW Co.

Floor Design and Fabrication

Stones:

Royal Botticino Marble

Bursa Dark Beige Marble

New Botticino Marble

Limra Limestone

This five-star Renaissance Hotel was built in the up-and-coming Putuo district of Shanghai. The contemporary interior, designed by VOA Architects, is themed around wind patterns. The client wished to add a floor pattern that was minimal and contemporary, yet bring in elements more organic than can be achieved with typical pavers or tile.

The floor pattern was developed to follow the curvatures of the ceiling patterns and the flow of traffic from entry to reception desk to guest rooms and through the bar and seating areas. The client also requested that the design include a representation of the RuYi, a ceremonial scepter or talisman, and a Chinese symbol of power and good fortune. This object was subtly integrated into the linear patterns of “wind.”

Because of the long curves of this pattern, the main challenge of this project was the fit from factory to jobsite installation. This was ensured through complete factory layout and dry-fitting at the site.

Also, to ensure the continuity of the pattern, the color, tone and texture of each of the four beige stones had to be carefully planned, so they would be clear and distinguishable from each other, yet subtle so as to not take away from the rest of the lobby features. The lobby and bar areas are approximately 8,000 sq. ft.

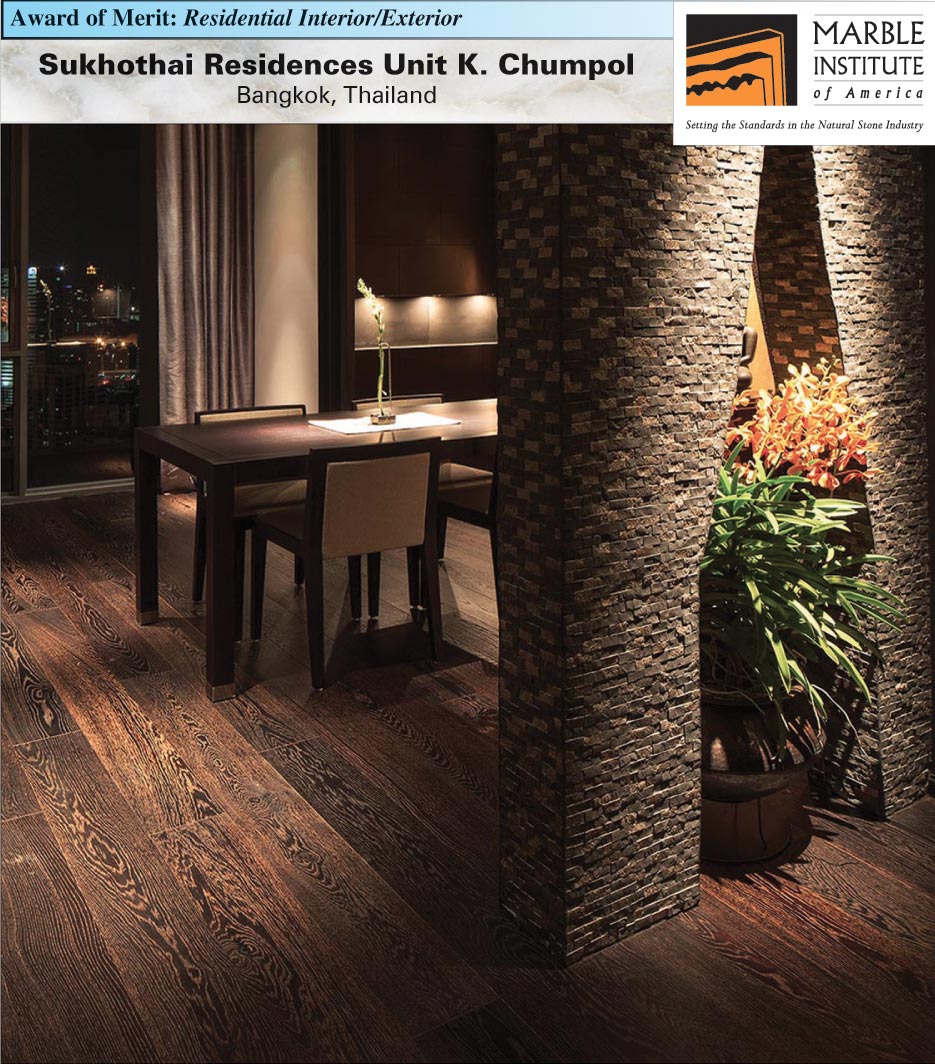

Sukhothai Residences Unit K. Chumpol

Sukhothai Residences Unit K. Chumpol

Bangkok, Thailand

MIA Member Company:

Stones and Roses

International Co. Ltd.

Samutprakam, Thailand

Stone Supplier

Stone Fabricator

Stone Installer

Other Project Team Members:

K. Chumpol Uchukamol

Client

Gooseberry Design

Architect

Classic House Furniture Co. Ltd.

General Contractor

Stones:

Black Basalt Granite

Sandstone Mosaic

Stanstead Granite

The design of the living room and dining room is primarily inspired by the architecture and interior design of the adjacent Sukhothai Hotel. There is an evocation of the Thai culture, religion and architecture. The design aims to theatrically create an atmosphere conducive of spirituality, serenity and refinement.

The main stone material, a honed black basalt, contributes to creating mystery and serenity. The plain black color of the stone reacts to the lighting featuring shades of medium grays to deep black which dramatizes the “mise en scene” of the Thai artworks.

The Thai style arch which separates the foyer from the dining area features a split face mosaic designed by Stones and Roses International. This mosaic mixes split face brown sandstone chips with titanium ore blocks. The choice of this material is inspired by the ancient Sukhothai temples and chedi which were originally built in bricks.

The mandala panel separates the dining area and the living room. It features concentric circles carved into the stone at increasing depths. The pattern with expressed joints is reminiscent of Angkor Wat where large stone carvings are built by stacking rectangular stone blocs in a geometrical pattern. It was a deliberate choice to execute this piece of work mostly by hand to bring a sense of humanity.

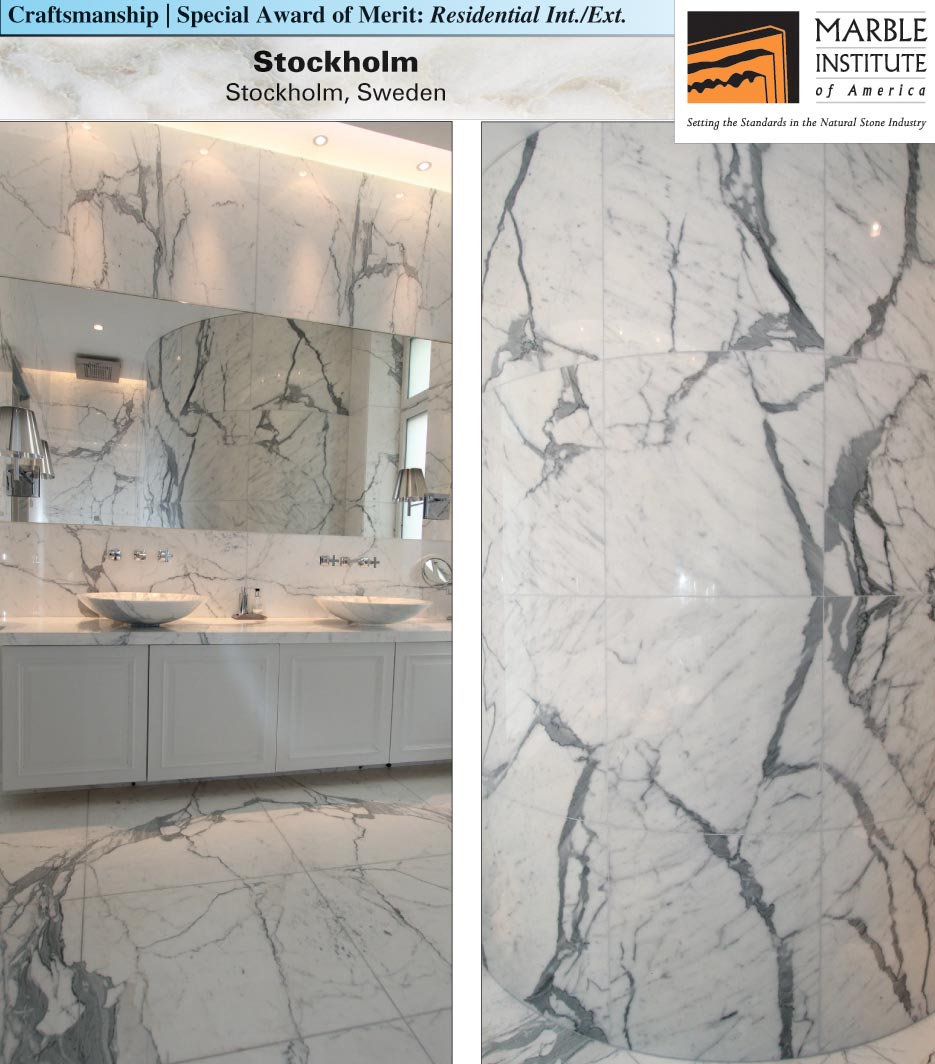

Stockholm

Stockholm

Stockholm, Sweden

MIA Member Company:

StenCentrum

Molndal, Sweden

Stone Fabricator

Stone Installer

Other Project Team Members:

Private Residence

Client

Samark Architecture and Design

Architect

Kungsfiskaren Bygg och

Fastighet AB

General Contractor

Santucci Armando

(MIA Member Company)

Stone Supplier

Stone:

White Statuario Marble

This project began four years ago in a meeting with architects. The meeting concluded with one goal; white statuario marble, very characteristic, big tiles and book matched. The pursuit for good material started immediately.

Most blocks did not fulfill the requests, but finally, one was found. It was a very sound block with the right dimensions and heavily veined. Realizing that it would be much more difficult to achieve the look with this strong veining, the project forged ahead. Before presenting the material to the client, the opportunities were discussed with the architects. Sketches were made of the best use of the material. The architects were very open-minded, realizing the difficulties of the project, but also very demanding regarding design and details.

StenCentrum staff went to Stockholm to measure the two bathrooms in question. After making drawings of the rooms, slabs were compared to the drawings spread all over the workshop. Realizing dimensions from the architect’s drawings could not be followed new sizes were created to follow the book matched pattern. Frames to doors, windows and shelves were carefully cut to book match the wall pieces.

Finally, when all the pieces were installed, the client said: “I would like to have the same stone on the curved wall in larger book matched pieces. I also want to be able to put a door in the middle of the wall in case we put a Jacuzzi on the other side.”

The project was a huge challenge, with a lot of ideas and requests from both client and architects. Without the supplier, my workshop and field staff, this project would not have been possible.