Pro-Seal Preserves from the Black Hills to China

by Joel Davis

Photos SuppliedCourtesy Pro-Seal

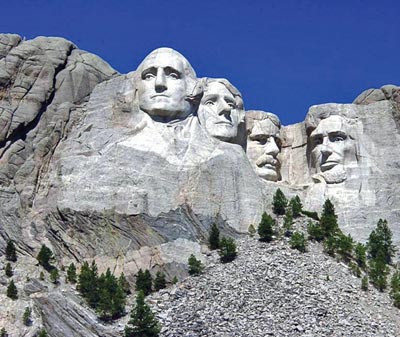

If Pro-Seal Systems Inc. can be entrusted to help save Mt. Rushmore, it’s safe to assume that it is up to the task of developing quality products for the concrete countertop industry.

If Pro-Seal Systems Inc. can be entrusted to help save Mt. Rushmore, it’s safe to assume that it is up to the task of developing quality products for the concrete countertop industry.

The Washington State-based company’s concrete repair and waterproofing materials have been used in the preservation of the Panama Canal, the Great Wall of China, the Empire State Building, and even faces of the U.S. presidents on Mt. Rushmore, CEO Tal Brammer said. “There are some of the biggest flagship projects in the world under our belt,” he said.

“We saved the features on the president’s faces on Mt. Rushmore. Solving the problem was a privilege. We were happy to do that.”

It’s not just the glamorous projects that attract Pro-Seal’s attention, however. The company offers more than 150 products to deal with water and fluid contaminant problems.

Of these, several are of interest to anyone who installs concrete countertops or works with decorative concrete.Will Kraft, a Pro-Seal sales specialist, minced no words about the company’s strengths. "We are the ultimate problems solvers," he said. “... Everybody is searching for the holy grail of concrete countertop sealers. It’s got to be acid resistant and easy to apply.”

Use the company’s Pro-Seal Ultra Shield II-A sealant, and you may just have completed that quest, Brammer said. “You are probably using the holy grail.”

Ultra Shield II-A, a hydrocarbon resistant film sealer, can improve the durability of concrete countertops. “It is the most popular (sealant) in that industry,” Brammer said. “It’s won a lot of awards.”

Industry feedback about the project has been very positive, Kraft said. “We work really closely with the guys who are doing this every day. The feedback we get from the leaders of this industry is this just works. It’s easy to lay down. It stands up to the wine and vinegar and all the things you see in a common kitchen.”

Although some contractors use burnishing pads or wheels when applying Ultra-Shield, others just use micro-fiber rags and a little elbow grease.

“You don’t have to mortgage your house to buy a special light to put this stuff down,” Will said. “It simply wipes on and off. It couldn’t be easier to apply.

”Some installers are turning to a combination of Pro-Seal products–either the DP-36 or the Pro-Seal R.O.C. Hard with the Ultra Shield II-A–to optimize the protection of concrete, Kraft said. “The nice thing is you are actually applying less Ultra Shield. There are big savings in cost, and it increases the durability of the countertop, too.”DP-36 increases the density of concrete by 10 to 23 percent by reacting with latent components within it. Those newly activated particles then fill up naturally occurring pores and air spaces, which reinforces its structural mass.

DP-36 also extracts fluid contaminants from concrete, including unwanted water, by forming a hydrostatic barrier that greatly reduces and, in many cases, stops water drive from the negative side. As part of a Pro-Seal system, it helps prevent freeze and thaw damage.Kraft is happy to advise customers on best practices in treating concrete countertops or decorative concrete.

“I keep my finger on the pulse of this industry so any time there is new information, I’m kind of a go-between,” he said. “People will call me for tips and tricks and for trouble shooting.”The company is willing to invest its time and resources into creating individual solutions to specific problems, Kraft said. “It’s more about tailor-making systems for specific problems rather than trying to throw one product at every problem.”

For example, Pro-Seal is currently working with the National Park Service to develop a system to stop erosion at some ancient Indian archaeological dig sites. The company is six years into a seven year test of the technology.

For example, Pro-Seal is currently working with the National Park Service to develop a system to stop erosion at some ancient Indian archaeological dig sites. The company is six years into a seven year test of the technology.

“People come to us with problems that can’t be solved with one material or another,” Kraft said. “We will typically design a system for their specific problem.”Developing a formula from scratch takes Pro-Seal about five years.

Designing a derivative of an existing product takes anywhere from six months to two years.

Brammer helped found the company 38 years ago. Its original focus was the construction industry. At the time, concrete sealants were not up to the task of dealing with the environmental conditions of day-to-day construction work. “We kept thinking that nothing is ever clean and nothing is ever dry, so we wanted to develop products that could be applied in adverse environments,” he said. “There was a lot of trial and error at the start. It took us a good six or seven years to really get ramped up and get something we considered... viable for the marketplace.”

The company developed a product to extract moisture out of materials like masonry, stucco, and concrete so sealer could be applied without waiting for summer or breaks in the weather, Brammer said. It also produced sealants, patching materials, and coatings that could be applied underwater or on surfaces that were wet or covered with acids, oil, or other contaminant fluids.“From there, our philosophy has grown and changed. Our products are ‘green’ in nature. In those days, it was ‘environmentally friendly.’ Today they talk about them as green.”

One of the highlights of the company’s achievements was securing the Panama Canal contract. Winning that contract was a coup for Pro-Seal, which took on far larger competitors and won, Brammer said. “We were a small company then, and we beat out some of the biggest players in the game in terms of performance.”

Brammer grew up in the glassmaking industry. He brought technology and techniques from that discipline into the Pro-Seal approach. “Why we are able to do what we do is a process called vitriforming. Basically, glass is a vitriform. Instead of following traditional chemical processes, we use a variant of that.”The company has one facility in the U.S. as well as facilities in China, Germany, and Greece. Domestically, it employs about 15 people at its Washington headquarters. Its production facility is highly automated, Brammer said. “We can do about 2.2 million square feet of product every eight hours.”

Currently, Pro-Seal is involved in some exciting projects overseas, Brammer said. China is laying about 1 million kilometers of elevated tracks for its bullet train system. The problem is the concrete components of the tracks are being destroyed by a variety of factors: acid rain, vibrations from passing trains, salt air, and the freeze/thaw cycle.

“We are working on a couple of very large projects in China. We’re working on railway tunnels in Shanghai. They have some significant groundwater infiltration issues. We’re stopping the flow of the groundwater from the inside of the tunnel.”

Brammer said the company continues to gather information about the performance of the products in order to keep improving them.

This has been especially useful in fine-tuning its offerings for concrete countertops. “We’ve made some huge leaps in the countertop market because there is more data readily available.”Pro-Seal is constantly seeking to tweaking its products or application techniques “to get better results or better scales of economy,” he said. The company is also very serious about the ensuring proper use of its products. “We have an authorized applicator program,” Brammer said.

This has been especially useful in fine-tuning its offerings for concrete countertops. “We’ve made some huge leaps in the countertop market because there is more data readily available.”Pro-Seal is constantly seeking to tweaking its products or application techniques “to get better results or better scales of economy,” he said. The company is also very serious about the ensuring proper use of its products. “We have an authorized applicator program,” Brammer said.

“The contractors work with us. We have a university here at our facility. It’s a pretty intensive learning process. ...The benefit of it is you have contractors who know exactly what they are doing.”

The company focuses on customer service, Kraft said. “One of the biggest advantages is our technical support. Whether its a DIYer or a contractor has was been doing this for a while and has a question, we’re always available to help them out.”

“A consumer can call in and talk to a product manger and get everything they need to know to do their home project,” Brammer said.

A Pro-Seal representative will return messages within 24 hours. If it is during regular business hours, they might even be able to talk immediately. “If (customers) have a problem they know they can always call somebody at Pro-Seal, and we’ll talk them through it,” Brammer said.

Anyone interested in distributing Pro-Seal Products or becoming an authorized applicator should call 425-488-6570. For technical support, call 800-349-7325 or email info@prosealproducts.com.