Rockcrete USA: Providing Price, Performance and Peace of Mind for 9 Years

Jennifer Holder

Special Contributor

(Hover over photos to see captions)

If it’s Friday, and you need a crew to start building a trench drain or floor drain for you on Monday, look no further than Rockcrete USA.

If it’s Friday, and you need a crew to start building a trench drain or floor drain for you on Monday, look no further than Rockcrete USA.

That’s the ease of Rockcrete USA’s revolutionary pour-in-place concrete forming system, Megamax Insta-Pour.

That’s the ease of Rockcrete USA’s revolutionary pour-in-place concrete forming system, Megamax Insta-Pour.

In fact, if you have a small budget and crew experienced in working with concrete, you might be able do the installation yourself.

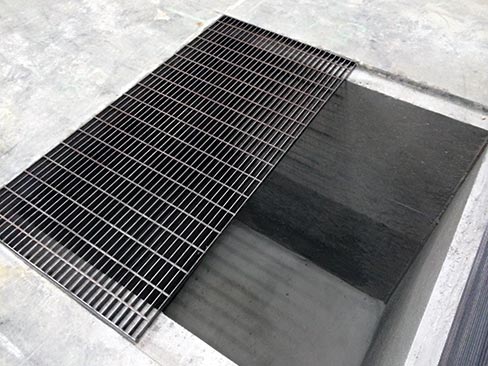

The product ranges from 4 to 48 inches wide with custom slope and grate options.

The product ranges from 4 to 48 inches wide with custom slope and grate options.

“The neat thing about this system that we developed,” says Rockcrete USA’s general manager, Hank Liebenberg, “It’s got a radius bottom built in – we can manipulate the slope.”

“The neat thing about this system that we developed,” says Rockcrete USA’s general manager, Hank Liebenberg, “It’s got a radius bottom built in – we can manipulate the slope.”

In fact, when talking about the product, the same three words came up in our conversation: ease, simplicity and strength. This system is stronger, simpler and easier to install and clean than almost any other trench drain system.

In fact, when talking about the product, the same three words came up in our conversation: ease, simplicity and strength. This system is stronger, simpler and easier to install and clean than almost any other trench drain system.

The Megamax Insta-Pour system has been around since 2005, but the latest upgrades were released at the beginning of 2013, when the company released the latest slick radius bottom development.

The Megamax Insta-Pour system has been around since 2005, but the latest upgrades were released at the beginning of 2013, when the company released the latest slick radius bottom development.

“It used to be a square bottom or radius bottom, [but] this is a super slick radius bottom,” says Hank.

Additionally, with a radius bottom, the trench is easier to clean and reduces sediment build up by up to 65 percent.

The system is also called the “pop and pour” because basically you can easily pop the system into the excavated trenches and then start pouring around it.

The system stays in place because there are alignment rods as well.

“We sell it in 8 ft sections with alignment rods that basically fit into each other, which prevents it from going out of alignment,” he says. “All 8 foot sections are numbered with arrows to indicate the direction of the flow, so you can’t go wrong. When you put it into position and you start pouring it’s not going to move anywhere.

“Normally people do multiple pours,” says Hank. “This is a monolithic pour which means…it’s much stronger. There are no corners which creates seams or weak points. It also saves a lot of time.”

In fact, Hank says that any corner is a weak point. “If you walk next to a brick building, the moment you see a corner – if it’s a real old building and there was some movement – it will start cracking in a corner. The same thing with a trench.”

Also, the trench drain holds whether you have heavy duty traffic or more light duty foot traffic. All you need is the right grate for your needs.

“We provide light and heavy duty grate options to allow for foot traffic or vehicle traffic. The grates are interchangeable.

“If you want to change your mind and start with a light duty area and later you want to get a forklift to drive over it, you can switch out the grates,” says Hank. “The base of the trench will allow for both uses but the grates determine what can drive over it.”

Rockcrete USA’s website shows their long list of clients, including everything from small granite fabrication facilities to bigger clients like New York City Department of Public Works, the US Navy and Sims-Lohman.

“Whether you need 12 feet or 1,000 feet, we’ll do it,” says Hank. “[If you need] 50 feet of trench drains in Knoxville, Tennessee, we’ll drive out there and go do it.”

They work all over the east coast, and have expanded toward the west coast to Arizona, and into Canada, and recently installed a 550-ft trench drain in L&M Laminates and Marble. Another recent job was in Duluth, Georgia, at Millworks Expressions, where they installed a 330-ft floor drain, and in Indianapolis, where a crew installed a 970-ft trench drain.

“Our [product] is very cost effective because it’s really light weight. It’s not that expensive to ship, and we can get in with a competitive price because of its easy installation.”

Rockcrete USA was created in 2005 and initially started doing machine foundations.

“Then we quickly saw there was a need for floor drains,” says Hank. “That is 90 percent of our business [now].”

And in the beginning, Hank helped install the floor drains.

“I did the jobs myself way back when the company started until we fine tuned our product and installation process.

We’ve gotten it down to a science now with what works best, what’s the most efficient, what’s the most economical way to approach a project,” he says.

They still do machine foundations, but it is a much smaller percentage of their business now.

The company is also proficient in project management from initiation to execution, including floor repair, polishing and resurfacing, and cutting, coring and drilling.

Everyone on the Rockcrete USA staff is on payroll - they do not use subcontractors.

“We would not be able to do it without them - reliable people,” says Hank.

“Your product can be as good as it gets but if you can’t rely on your people it’s impossible to pull through That’s how we live up to our slogan: Price, Performance and Peace of Mind.”

With Rockcrete, the job will get done quickly and efficiently no matter what.

The crews work together, and Hank makes sure to communicate with them regularly, and is always available to lend a hand or troubleshoot.

“I talk to the people who get down and dirty on-site every day. We know what’s going on on-site, at all times” he says.

Rockcrete USA’s system, Megamax Insta-Pour is proof that the company is here to stay.

Their annual sales are up an estimated 25 percent from last year. And from the testimonials on their website, it’s clear that they always do an excellent job for their clients.

For more information on Rockcrete USA and the Megamax Insta-Pour system, check them out online at www.rockcreteusa.com or call them at 877-999-1175.