J.C. Stone: From Quarry to Client

Custom-Sawn Natural Stone Products from Maine

by Peter J. Marcucci

Photos by Peter J. Marcucci

Additional Photos by J.C. Stone

From quarry to client, J.C. Stone offers New England’s largest variety of custom-sawn natural stone products.

From quarry to client, J.C. Stone offers New England’s largest variety of custom-sawn natural stone products.

With a stone-rich lineage since 1995, Jamie Carle and wife Kathleen Carle have been doing business in Jefferson, Maine as J.C. Stone Inc. since 2000, but this story and its humble beginnings can be traced back to the small town of Washington, Maine as Jamie and his then partner drove load after load of landscape stone from the quarry to clients —usually local landscapers.

With a stone-rich lineage since 1995, Jamie Carle and wife Kathleen Carle have been doing business in Jefferson, Maine as J.C. Stone Inc. since 2000, but this story and its humble beginnings can be traced back to the small town of Washington, Maine as Jamie and his then partner drove load after load of landscape stone from the quarry to clients —usually local landscapers.

If it could be peeled off the mountain, they loaded it into their dump truck and found a buyer. As time passed and sales increased, so did the extraction process and inventory. A new market had been created, and the sales yard was filled with Maine’s finest veneers, flagstones and wall stones. The writing was on the wall, the contracts were getting inked and the bills were being paid. The back-breaking work was paying off, and success was on the horizon, but, says Kathleen Carle, it was smart management, industry prowess and marketing savvy that brought J.C. Stone Inc. to its current level of success in just over decade.

If it could be peeled off the mountain, they loaded it into their dump truck and found a buyer. As time passed and sales increased, so did the extraction process and inventory. A new market had been created, and the sales yard was filled with Maine’s finest veneers, flagstones and wall stones. The writing was on the wall, the contracts were getting inked and the bills were being paid. The back-breaking work was paying off, and success was on the horizon, but, says Kathleen Carle, it was smart management, industry prowess and marketing savvy that brought J.C. Stone Inc. to its current level of success in just over decade.

“When the company first started, Jamie was working at a quarry with a partner and two other guys doing landscape stone,” said Kathleen.

“When the company first started, Jamie was working at a quarry with a partner and two other guys doing landscape stone,” said Kathleen.

“Then, when this property became available, he came home one day and said, ‘What do you think about opening up a stone center?’ I just said, I guess we can try it!—and ever since then we’ve just grown. It’s been wonderful. We went from landscape stone with two guys, to a thriving company of 46 employees in 2008.”

“Then, when this property became available, he came home one day and said, ‘What do you think about opening up a stone center?’ I just said, I guess we can try it!—and ever since then we’ve just grown. It’s been wonderful. We went from landscape stone with two guys, to a thriving company of 46 employees in 2008.”

With the purchase of several local quarries, the company of humble beginnings had gone through a massive transformation in just five years and was on a roll. Quality stone products were going out the door and company growth was the byproduct. But it wasn’t that easy. The calculus changed one fateful early morning when the phone rang.

With the purchase of several local quarries, the company of humble beginnings had gone through a massive transformation in just five years and was on a roll. Quality stone products were going out the door and company growth was the byproduct. But it wasn’t that easy. The calculus changed one fateful early morning when the phone rang.

“In 2007 we had just signed on a big project in Boothbay Harbor,” explained Kathleen. “Soon after, we had a phone call at four o’clock one morning saying there was a fire and we no longer had a saw shop, so it was a little crazy. We began to rebuild, and the guys during the day would cut with hand saws while at night we were constructing our new building. That fire transformed J.C. Stone yet again, and those guys were a big part of keeping us going as well as helping us rebuild.”

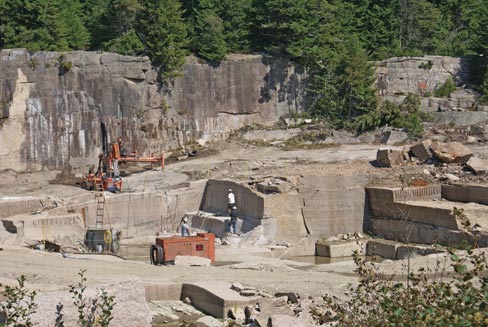

Located on 13 acres, the Carle’s shop to date is fed by seven granite quarries of remarkable beauty and colors, with their “Heritage Valley” line being their signature stone.

The all-under-one-roof shop houses a cache of G.M.M. block and bridge saws as well as a Park Industries Python II, while a Flow waterjet, G.M.M. lathe and Bidese Impianti contour wire saw serve to do shaping. A Thibaut surface polisher rounds out the arsenal. To facilitate movement of materials throughout the fast- paced shop, a 3-axis overhead crane spanning the entire work area makes optimal use of the 13,500 sq. ft. building, while two jib cranes satisfy the more intensely used areas. During the tour Jamie was eager to point out that they work closely with the Maine Department of Environmental Protection and employ ecologically friendly techniques during fabrication and quarrying, using closely monitored run-off ponds in the quarries and a huge, slightly “tricked out” Fraccaroli Balzan water filtration system throughout the shop. Clean environmental manufacturing and safety for the 32 employees are top priorities according to the Carle’s.

“We are 100% closed loop in this shop, which is huge—especially for a company this size,” said Jamie. “The filtration system came with an electric pump, and we replaced it with an air operated pump, and now it works flawlessly. It can pump 24 hours a day.”

“We have many of our original employees,” Kathleen added, “and they are fun, they are hard working, and they like what they do. We try very, very hard to keep our people safe by offering classes and getting them everything they need to work safely and efficiently.”

When asked about being able to hold their prices, Jamie remarked, “We have our own quarries and that gives us a competitive edge while still keeping our prices up, but you still have to be competitive. We had grown so much and then things slowed down in 2008, and we had to diversify. We went more into commercial work looking for more volume. At one point we were running three shifts, seven days a week, twenty-four hours a day for nineteen months just trying to keep the volume. We then dropped the volume and went back to 40 hours per week with more quality jobs.” Pointing to a block of Heritage Valley granite as we continued to walk, he turned and said, “This is a premium block and it’s high-end residential. It looks like an exotic marble when it’s cut into a slab with the grain and polished. Heritage Valley also makes great veneer or pavers. It’s also a very hard stone.”

Equipment for those quarries includes three Caterpillar 988s, a T-REX forklift, multiple wire saws as well as all the necessary gear to operate three quarries at any one time. Moreover, the Carle’s said that as far as available colors from their quarries, Heritage Valley is their signature stone, but their granites such as Englishman’s Bay, Jonesboro Red, Northern Mahogany, Oak Hill and others are longtime favorites, especially with New England’s finest builders and sculptors.

“We’ve been in business for 16 years, and whether it’s honed, polished, brushed or bush hammered, we can create a nice finish on each of our colors,” said Jamie. “Building, cladding, paving or slab, we try to stay in the residential market as much as possible, but we’re about 75% commercial right now. We cut 2 and 3cm slabs and do surface polishing for jobs we are working on such as outdoor or indoor kitchens or bathrooms, just not on a large scale at this time. As we progress, we will probably send out those same blocks to Canada to have them cut into 2 and 3cm slabs, polished and returned to us. We will then put them on the market depending on the colors, but right now the market is so saturated that we stay mostly with dimensional and landscape stone.”

“We’ve been in business for 16 years, and whether it’s honed, polished, brushed or bush hammered, we can create a nice finish on each of our colors,” said Jamie. “Building, cladding, paving or slab, we try to stay in the residential market as much as possible, but we’re about 75% commercial right now. We cut 2 and 3cm slabs and do surface polishing for jobs we are working on such as outdoor or indoor kitchens or bathrooms, just not on a large scale at this time. As we progress, we will probably send out those same blocks to Canada to have them cut into 2 and 3cm slabs, polished and returned to us. We will then put them on the market depending on the colors, but right now the market is so saturated that we stay mostly with dimensional and landscape stone.”

The Beginning Of A Bequest by the Carles, As Told By Kathleen

“Jamie and I had gone to a Maine Stone Workers Guild meeting in 2005 as corporate members and talked to a lot of the artists and members to learn more about them. When we left, Jamie and I talked about holding a sculpture symposium at J.C. Stone. By 2010 we had gotten to know many of those artists including Don Meserve, Andreas von Huene and Dan Ucci. I had also been talking with someone at the Maine Botanical Gardens about J.C. Stone hosting a symposium. I still wasn’t sure what I wanted to do and I was just throwing the idea out there.

“Jamie and I had gone to a Maine Stone Workers Guild meeting in 2005 as corporate members and talked to a lot of the artists and members to learn more about them. When we left, Jamie and I talked about holding a sculpture symposium at J.C. Stone. By 2010 we had gotten to know many of those artists including Don Meserve, Andreas von Huene and Dan Ucci. I had also been talking with someone at the Maine Botanical Gardens about J.C. Stone hosting a symposium. I still wasn’t sure what I wanted to do and I was just throwing the idea out there.

Eventually I called Don Merserve and told him what I was doing and he said, ‘That’s a fantastic idea — let’s keep the ball rolling!’ Don then called me back not even two months later and said, ‘I don’t want to wait.’ And as soon as he said that I knew something was wrong. I said tell me how to do this — point me in the right direction and we’ll make it happen. So Don hooked me up with local artists Dave Sywalski and Dan Ucci while he was calling local artists. My biggest thing was that I wanted Maine artists using Maine stone. After meeting these artists in 2005, I felt that sculpture was an under-appreciated art. I then contacted Maine Home and Design Magazine and told them what we were up to. They got on board and helped sponsor the show with their photography and advertisements and did an incredible job promoting it. Before it began I said to Jamie, let’s just give back. I want recognition for these artists, I want them comfortable here and I want them to pick through our stone and people to commission their art. Most of the artists loved it because they don’t get to work with bigger stone. They all have their studios but don’t have the large equipment to move or flip the large stones. The deal was that you come here, I will help you sell your piece when finished and you keep the money. The artists were allowed to use any block on the lot. I can’t tell you why, but it was extremely important for me to do this. That symposium was in 2010.” (Please note: Don Merserve, who passed away in 2010, was a world-class sculptor who was loved by many and is missed by everyone.)

Eventually I called Don Merserve and told him what I was doing and he said, ‘That’s a fantastic idea — let’s keep the ball rolling!’ Don then called me back not even two months later and said, ‘I don’t want to wait.’ And as soon as he said that I knew something was wrong. I said tell me how to do this — point me in the right direction and we’ll make it happen. So Don hooked me up with local artists Dave Sywalski and Dan Ucci while he was calling local artists. My biggest thing was that I wanted Maine artists using Maine stone. After meeting these artists in 2005, I felt that sculpture was an under-appreciated art. I then contacted Maine Home and Design Magazine and told them what we were up to. They got on board and helped sponsor the show with their photography and advertisements and did an incredible job promoting it. Before it began I said to Jamie, let’s just give back. I want recognition for these artists, I want them comfortable here and I want them to pick through our stone and people to commission their art. Most of the artists loved it because they don’t get to work with bigger stone. They all have their studios but don’t have the large equipment to move or flip the large stones. The deal was that you come here, I will help you sell your piece when finished and you keep the money. The artists were allowed to use any block on the lot. I can’t tell you why, but it was extremely important for me to do this. That symposium was in 2010.” (Please note: Don Merserve, who passed away in 2010, was a world-class sculptor who was loved by many and is missed by everyone.)

The Future

When asked what the future holds for J.C. Stone, Kathleen gently responded, “We love quarries—especially in Maine and I think we’ve done a good job of resurrecting the quarry industry here. Our market is very strong in New England, and we are currently expanding west. Our goal is to become even more available in these states. We see a bright future in the growth of our landscape stone and intend to put more block colors on the market. We will also continue to stay heavily involved with the Viles Arboretum as well as symposiums such as the Schoodic International Sculpture Symposium, but no on-site symposiums are in the works for the near future.”

J.C. Stone Inc. is a fast-paced, supercharged company engineered to produce all types of fabricated stone quickly and accurately. The Carles and their crew are the perfect combination of steely discipline and market sensibility. They are not the Fast and Furious—they are the Adept and Accurate, offering clarity and great products to clients in a sometimes murky market place. They bring character and class as well as tradition and renaissance to an industry that once produced a specialty, not a commodity. They are also recipients of the Marble Institute of America Pinnacle Award in 2009 for their contribution to the restoration of the Bowdoin College Museum Of Art in Brunswick, Maine and can always be counted on to selflessly support the visual arts. J.C. Stone Inc. is truly a world-class, full spectrum stone company that works in the present, and owns the future.